Whether you need a handheld, manually loaded, or fully automated laser cleaning solution, our experts can assist you in selecting the right machine and options. Paint, oxide, rust, and other contaminants can be removed from metal surfaces using our machines. With laser texturing, they can also improve surface adhesion.

Laser Cleaning Machine Parameter

| MODEL | HP 100 | HP 200 | HP 300 |

|---|---|---|---|

| Size | 350*450*700mm | 900*560*100mm |

1015*730*1100mm |

| Power | 100/200/500/1000W | ||

| Speed | ≤10000mm/s | ||

| Mode | Manual / Auto | ||

| Cooling System | Water cooling | ||

| Working Temperature | 0-40℃ | ||

| Working Standard | 160 Standard, 210, 250, 300mm | ||

| Fiber Length | 4.5M / 10M Standard | ||

| Demand Vibration | Less than 0.98m / ≤2(1G) 10 60HzTransportation Less than 4.9m / ≤2(0.5G) | ||

| Power Source |

100-200W: 200V 50KHz 500-1000W: 380V 50KHz |

||

Product Details Display

Minimal Maintenance

The strength lies in its ability to operate without the need for regular upkeep, resulting in reduced time, effort and costs associated with maintaining its functionality.

Multiple Scanning Modes

Six cleaning modes can be provided (only one linear mode for single axis ), which can be switched freely according to the actual scene requirements.

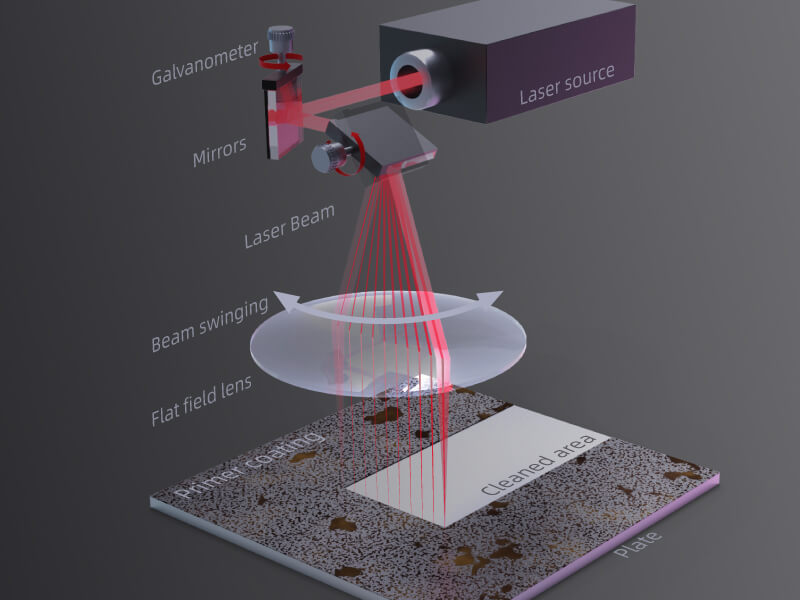

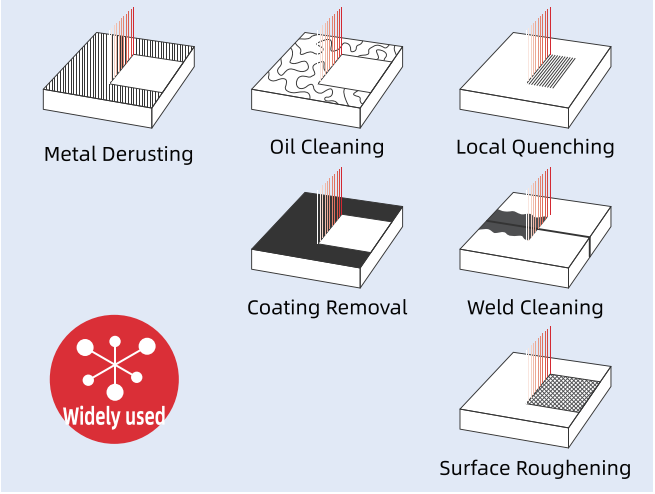

Laser Cleaning Solutions

Laser cleaning machine can be used for metal rust removal, oil cleaning, local quenching, surface roughening, coating removal, weld cleaning.

Benefits of Laser Cleaning

An easy-to-operate product reduces the learning curve for users, enabling them to use the machine confidently with the minimal likelihood of errors or misuse.

Laser cleaning effect

Laser cleaning can remove various types of contaminants from the surface of various materials, to achieve a cleanliness that can not be achieved by conventional cleaning. It can also selectively clean the material surface without damaging the material surface

Are you interested in our product?

Please feel free to contact us, we would like to help you with advice and support.

상품평

아직 상품평이 없습니다.