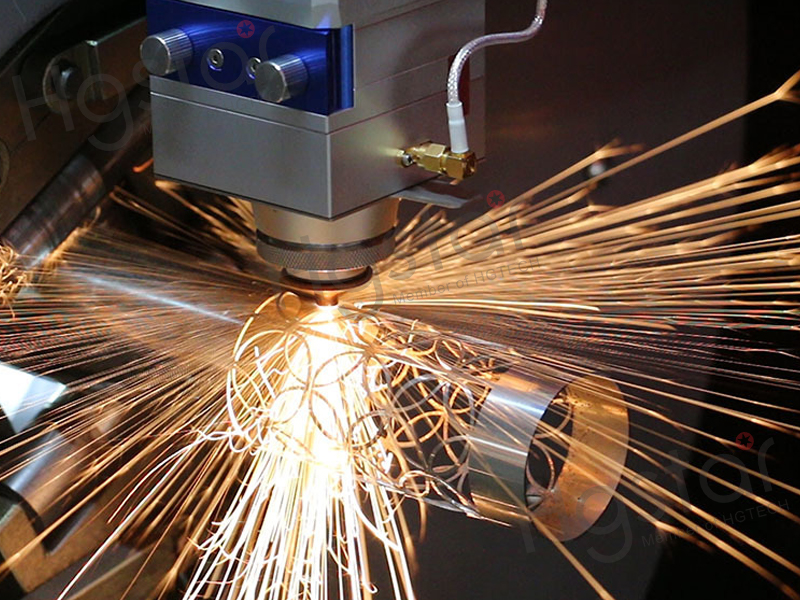

With the continuous development and improvement of metal tube laser cutting machines in recent years, the degree of use of metal tube laser cutting machines has increased. The use of metal tube laser cutting machines has changed many industries and accelerated the development of sheet metal processing, hardware cabinets, elevator processing, hotel metal users, and other industries.

Laser cutting, as an important cutting technology in the laser processing industry, can account for up to 70% of the total, demonstrating the breadth and importance of its application. Laser cutting technology is an important part of laser processing technology, and it is also recognized as one of the most advanced cutting technologies in the world.

Metal furniture is becoming more common in everyday life. Metal furniture, whether in the home or in public places, is attractive, long-lasting, and simple to clean. It has gradually replaced traditional wooden furniture and has become the new home favorite. Metal tube laser cutting machines, or laser pipe cutting machines, are commonly used in the production of metal furniture because the cutting of metal planes and metal plates is involved.

In fact, many metal products in modern homes are processed using metal tube laser cutting machines. This is due to the higher processing quality required for metal furniture, particularly the quality of cut sections. Traditional methods of metal processing are difficult.

Picking-sawing machine Blanking-lathe processing, bevel-drilling position proofing, and punching-drilling-cleaning-transfer welding are the nine processes involved in the traditional furniture industry manufacturing process.

As a result, the price of metal furniture used to be very high, but now that metal tube laser cutting machines are used for metal processing, not only is the cutting speed fast, but any graphics can be cut, the cutting mouth is smooth, there is no burr, there is no mold consumption, and there are no other problems.

In this age of individuality, metal tube laser cutting machines can produce a wide range of furniture products at the same cost and output as traditional processing methods. While refined processing was required, it solved many problems and enabled product diversification and multi-function.

Cutting boards can be processed using furniture products. To meet market demand, the laser cutting machine realizes the sophisticated cutting machine accuracy function, increases processing efficiency, lowers costs, and discovers a new starting point for modern furniture design. Incorporate a new experience and a different way of life into modern home décor.