Preface

In recent years, thanks to the rapid development of the new energy industry, laser welding has rapidly penetrated the entire new energy industry due to its fast and stable advantages. Among them, the application proportion of laser welding equipment is the highest in the entire new energy industry.

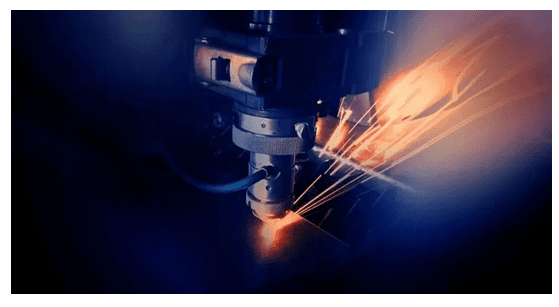

Laser welding has quickly become the preferred choice for various industries due to its fast speed, large depth, and small deformation. From spot welding to butt welding, overlay welding, and seal welding, laser welding provides unparalleled accuracy and control. It plays an important role in industrial production and manufacturing, including military, medical, aerospace, 3C automotive parts, mechanical sheet metal, new energy and other industries.

Compared with other welding techniques, laser welding has its unique advantages and limitations.

Multiple advantages of laser welding

- 1. Fast speed, large depth, and small deformation.

- 2. Laser welding can be carried out at room temperature or under special conditions, and the welding equipment is simple. For example, a laser beam will not drift in an electromagnetic field. Laser can be used for welding in vacuum, air, or certain gas environments, and can also weld materials that pass through glass or are transparent to the laser beam.

- 2. Can weld difficult to melt materials such as titanium and quartz, and can also weld dissimilar materials with good welding results.

- 3. After laser focusing, the power density is high. The aspect ratio can reach 5:1, and the highest can reach 10:1 when laser welding high-power devices.

- 4. Laser micro welding is possible. After focusing the laser beam, small light spots can be obtained and accurately positioned, which can be applied to the assembly and welding of micro and small workpieces, achieving batch production automation.

- 5. It can weld difficult to reach areas and perform non-contact long-distance welding, with great flexibility. Especially in recent years, laser processing technology has adopted fiber optic transmission technology, making laser welding technology more widely promoted and applied.

- 6. Laser beams are easy to achieve time and space splitting, and can be processed simultaneously by multiple beams at multiple positions, providing conditions for precision laser welding.

Limitations of laser welding

- 1. High assembly accuracy is required for the workpiece, and there should be no significant deviation in the position of the beam on the workpiece. This is because the laser spot size after focusing is smaller, the weld seam is narrower, and it is difficult to add filler metal materials. If the assembly accuracy of the workpiece or the positioning accuracy of the crossbeam cannot meet the requirements, welding defects are prone to occur.

- 2. Laser and its related systems have high costs and a large one-time investment.

Summary

When selecting laser welding equipment, in addition to referring to the advantages and limitations of laser welding, a comprehensive evaluation and selection should also be made based on the actual situation.