Introduction

In the high-precision and high demand field of aviation industry, laser 3D cutting technology is increasingly demonstrating its strong potential and value. This technology not only improves the manufacturing efficiency of aviation components, but also ensures the accuracy and quality of the components, providing strong support for the manufacturing of modern aircraft.

Application advantages in the aviation industry

1. Precision manufacturing of complex components

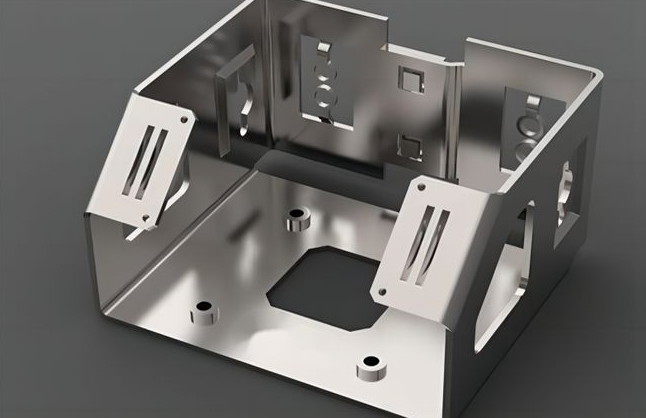

Many components in the aviation industry have complex structures, and traditional processing methods are difficult to handle. Laser 3D cutting can accurately and quickly manufacture these complex structures, such as engine blades, fuselage frames, etc.

2. Wide material adaptability

Whether it is metal, non-metal, or composite materials, intelligent equipment for large-area high-power laser groove cutting can demonstrate good processing results. This makes laser cutting an ideal choice for processing multiple materials in the aviation industry.

3. Improve production efficiency

Laser cutting has a fast speed and high degree of automation, which can greatly reduce processing time and labor costs, and improve production efficiency.

Challenges Faced

1. High technical difficulty

Laser cutting requires precise control of the path, speed, and power of the laser beam, which requires extremely high technical proficiency from operators.

2. Material limitations

Although laser cutting can process multiple materials, the effectiveness of laser cutting may be affected for certain special materials, such as high reflectivity materials or certain composite materials. In the aviation industry, the application of these special materials is quite extensive, so the application of laser cutting in these situations is somewhat limited.

3. Working environment limitations

Laser cutting equipment requires a stable working environment, such as temperature, humidity, vibration, etc., which need to be controlled within a certain range. In the production site of the aviation industry, these environmental factors may be affected by various factors, thereby affecting the effectiveness and stability of laser cutting.

4. Cutting thickness limitation

Laser cutting has certain limitations for thicker materials. As the thickness of the material increases, the difficulty and cost of laser cutting will also increase accordingly.

Future outlook

With the continuous development of technology, laser technology is also constantly advancing. In the future, we can look forward to the emergence of more advanced and intelligent laser cutting equipment, bringing greater convenience and benefits to the aviation industry. Meanwhile, with the continuous emergence of new materials, the application scope of laser cutting technology will also be further expanded.