The era of myriawatt laser cutting machines has arrived

With the pursuit of efficiency and process in the entire processing and manufacturing industry, laser cutting technology continues to make breakthroughs. With its unique advantages such as high power, high efficiency, and high stability, Wanwa laser cutting machines are warmly sought after by the entire industry. The era of 12kw fiber laser cutting machines has arrived, owning ten thousand watts leads the future.

Why are 12kw fiber laser cutting machines popular

At present, the most popular laser cutting power in the market is in the tens of thousands of watts, and the most popular among them is the 12KW laser cutting machine, which occupies a large market share with its excellent performance and price advantages.

Advantage 1: Significant increase in cutting limit thickness

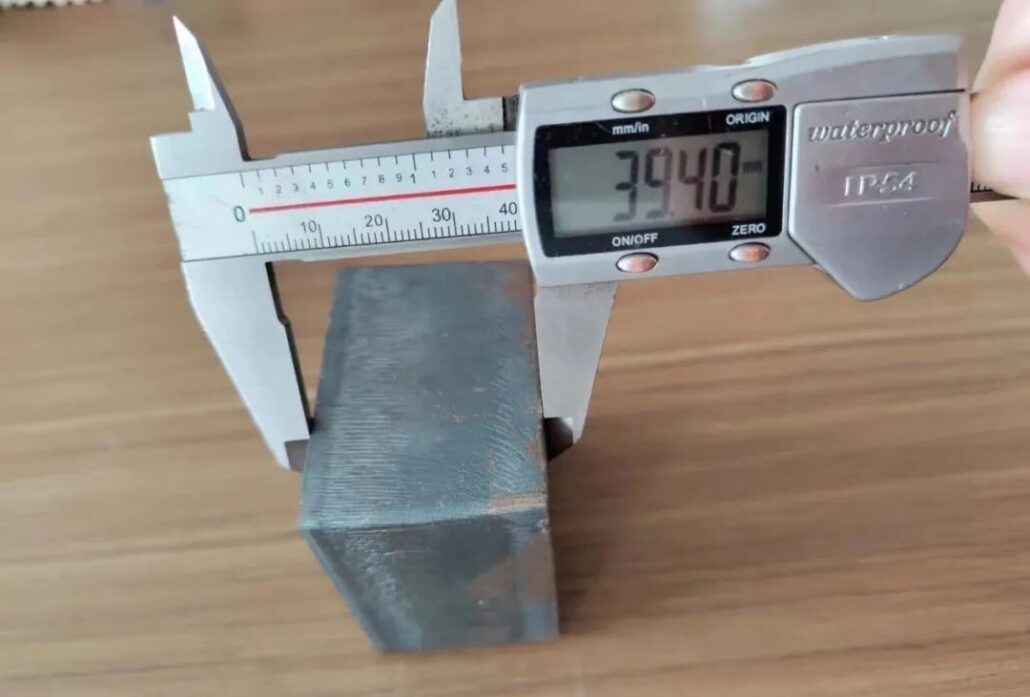

The cutting limit thickness of the 12kw fiber laser reaches 40mm or more, and the carbon steel reaches 50mm, and the cutting cross-section effect is good.

Compared to lower power lasers, the improvement in cutting ability has made a qualitative leap, resulting in a huge increase in the processing range of laser cutting machines.

Advantage 2: Significant improvement in cutting speed

When selecting the power of laser cutting equipment, the cutting speed of different materials is a key factor to consider. The application of fiber laser cutting has significant advantages in the processing of medium and low thickness plates, and the increase in laser power can accelerate the cutting speed.

The increase in speed brings about an exponential increase in the economic benefits of fiber laser cutting machines. Especially for medium thickness materials currently used for fiber optic cutting, the increase in cutting speed can reach more than twice.

Advantage 3: Increased diversity of cutting processes

In addition to the advantage of cutting thicker and faster, as the laser power increases, the laser cutting process can also create more patterns. For example, the highly acclaimed high-speed bright surface cutting technology and thick plate small hole cutting technology currently available.

Epilogue

At the same time, with the significant advantages of the Wanwa series, the market is starting to develop towards higher power, moving from 12KW to 20KW or even 30KW in an attempt to achieve more possibilities. Higher power equipment has also stirred up a whirlwind in the market with its unique advantages. Everyone couldn’t help but start thinking, is higher power better? Which power has the highest cost-effectiveness? Which one is more suitable? Regarding these, many people may also have doubts. In fact, for different users, due to the different processing materials and product requirements of each company, the production needs are also different.

So choosing what suits oneself is the most important thing, not the higher the better.