In recent years, laser handheld welding has become a dark horse in the field of laser applications, with an annual compound growth rate of over 100%. At the recent Essen Welding Exhibition, laser companies’ handheld welding products bloomed, and many companies engaged in traditional welding also began to enter the field of laser handheld welding.

The advantages of laser handheld welding

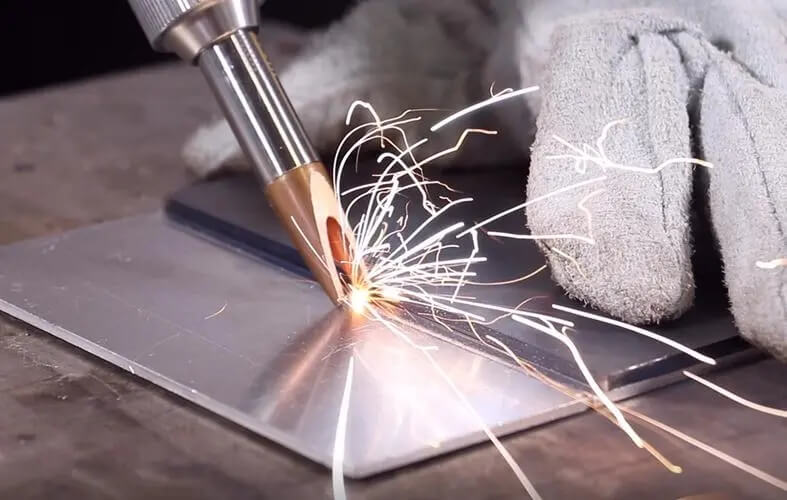

China’s manufacturing industry is undergoing upgrading, and advanced products and technologies will inevitably eliminate outdated production capacity and technology. Laser handheld welding has many advantages such as fast operation, beautiful welds, low overall cost, and environmental protection, which can solve the problems existing in some welding scenarios. Laser beam welding can realize the thin plate welding without deformation and discoloration, and the welding speed is 4~10 times faster than the traditional arc welding.

Moreover, laser handheld welding can greatly eliminate steps such as pre welding cleaning and post welding polishing for factories, effectively saving production time and labor costs. In particular, some thin iron plates and aluminum alloy plates used for splicing can neither be polished (easily damaged) nor spattered. Laser beam welding has obvious advantages over traditional welding in these fields.

Although there are still shortcomings in many fields of laser handheld welding, manufacturers can bring users more abundant programs and more comprehensive services through Laser beam welding.

Challenges Faced by Laser Handheld Welding

At present, laser handheld welding mainly involves low-power lasers below 3000W, which are used in the thin plate welding market such as kitchen utensils and sheet metal. However, it is powerless in the field of thick plate welding above 10mm. In addition, in some small household welding machines, laser handheld welding also lacks competitiveness. For example, if a bicycle leg is broken, it can be easily welded with just a few clicks, and the price of this type of small welding machine is low.

Overall, laser mainly replaces the argon arc welding market for welding thin plates. Therefore, although laser welding has developed rapidly in the past few years and occupied a certain market, its overall share is not high.

At present, laser handheld welding is limited in power and can only weld thin plates. However, in the future, it will definitely develop into the field of thick plates, and the laser power will also increase accordingly. High power lasers can cause harm to human skin and eyes. In the future, higher power welding machines will not only require enhanced employee protection, but also require assistance from cantilevers, robotic arms, and other devices.

As an important puzzle in the field of welding, laser handheld welding has made up for some of the shortcomings of traditional welding processes and improved user experience, thus gaining recognition from traditional welding manufacturers.

At the same time, laser handheld welding will not truly “completely replace” a certain welding process, after all, the welding application scenarios are very diverse, and many scenarios are not suitable for using laser handheld welding. Therefore, the coexistence of multiple processes can truly meet user needs.