Laser cleaning technology has many advantages that traditional cleaning methods can not reach, in order to ensure the cleaning effect, you can choose different wavelengths of laser according to the difference in laser absorption rate of the cleaned object at different wavelengths.

Demand Of New Laser Cleaning Technology

However, for the cleaning of composite materials, if the absorption rate of different components in the material is very different for the same laser wavelength, there may be a phenomenon that some components of the material are successfully cleaned while other components cannot be removed.

Development Of Laser Composite Cleaning Technology

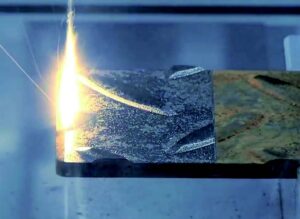

In order to solve the related problems, a variety of new laser composite cleaning technology came into being. As early as 1977, there was research on laser cleaning of composite materials. The laser composite cleaning method has the advantages of fast speed, high efficiency, more uniform cleaning quality, and smaller sparks and smoke.

For different materials, lasers of different wavelengths can also be used for cleaning at the same time to achieve the purpose of removing composite material stains, effectively solving the problem that traditional laser cleaning technology is difficult to clean composite materials.

Composite laser cleaning technology can achieve the efficiency of 1000W pure pulse laser cleaning machine with 4000W continuous +500W pulse, and achieve the efficiency of 2000W pulse cleaning machine with 6000W continuous +1000W pulse.

Advantages Of Laser Composite Cleaning Technology

However, the advantages of laser composite cleaning technology are not only the superposition of two lasers, but also the energy utilization rate is much greater than the simple addition of two heat sources.

In the laser cleaning of thick coating materials, due to the large output of multi-pulse energy of a single laser and the high cost of high-power pulsed laser, the laser cleaning of thick coating materials is limited, and the pulsed laser-semiconductor laser composite cleaning can quickly and effectively improve the cleaning quality, and the substrate is not easy to cause damage.

In the laser cleaning of highly reflective materials such as aluminum alloy, a single laser has problems such as large reflectivity, and the use of pulsed laser-semiconductor laser composite cleaning, due to the role of semiconductor laser thermal conductivity transmission, increases the energy absorption rate of the oxide layer on the metal surface, so that the pulsed laser beam can peel the oxide layer faster, so as to more effectively improve the removal efficiency.

On the basis of the same price, the cleaning efficiency is doubled 2-3 times by process improvement. It has the advantages of improving the cleaning quality, increasing the cleaning efficiency, stabilizing the cleaning process, and being suitable for the cleaning of high reflective materials, so as to avoid the shortcomings and shortcomings of a single cleaning.