Preface

The global automotive industry has undergone significant changes, and with the increasing call for energy conservation, emission reduction, and improved driving experience, a trend of “lightweight” has emerged in the automotive manufacturing industry. Reducing self weight to achieve lightweight of automobiles has become a breakthrough point for major automotive companies, which has put forward higher requirements for automotive panel processing. Laser uncoiling and material cutting technology, with its unique advantages, has gradually become a new favorite in the industry.

Four major processing difficulties

Hot formed parts are the key to weight reduction and ensuring vehicle safety, but four major processing difficulties urgently need to be solved:

① Hot formed parts have high tensile strength and complex shapes;

② Traditional stamping processes require long development time for mold opening and processing;

③ Fast mold loss and high investment cost;

④ The machining accuracy of the mold is insufficient and there are errors.

How to ensure high precision and quality of workpiece dimensions after forming? How to solve the defect of low forming rate of complex workpieces? We also need to focus on practical applications in the industry and attach importance to real user feedback.

The advantages of solving processing difficulties

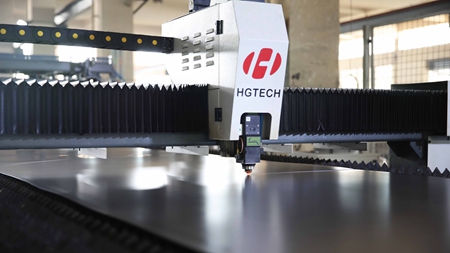

The coil feeding laser punching line integrates multiple processes such as laser cutting, coil processing, and material forming, achieving efficient and accurate continuous production. This technology not only significantly improves production efficiency, but also brings many benefits to the processing of automotive panels. Firstly, it can precisely control the use of materials according to the needs of different components, thereby achieving maximum utilization of materials and reducing costs. Secondly, thanks to the addition of the coil fed laser cutting system, laser uncoiling and material cutting technology can quickly respond to various complex shape processing needs, improving the forming rate of the workpiece. Finally, due to the use of non-contact machining throughout the entire machining process, the loss and error of molds in traditional processes are avoided, resulting in better assurance of the accuracy and quality of the workpiece.

It is worth noting that laser welding is one of the key technologies in the automotive manufacturing process. It connects plates of different thicknesses, materials, or performance into a whole through laser cutting and assembly technology, and then forms a certain part of the vehicle body through stamping. The online circle feeding laser cutting line adopts laser welding technology, which can significantly reduce the number of parts and molds, optimize material usage, and have a cost reducing and efficiency increasing effect.

Summary

The laser uncoiling and feeding line can not only accurately cut and save materials in batch production, but also respond well to various material shapes under the control of the coil feeding laser cutting system, saving time required for mold replacement. We have solved our four major processing difficulties very well.