What Exactly Is Laser Cutting? There are several types of laser cutting, but in general, it uses a highly concentrated stream of photons to cut various materials such as metal. Depending on how you program it, they can make basic cuts, carve intricate shapes, or even engrave designs on the surface of a material. To…

At present, most popular laser welding machines are in the form of water-cooled refrigeration. The weight of the whole machine with coolant is about 300-400kg, which is inconvenient to carry. In terms of size, a car cannot be installed. At least a pickup truck is required to put it down. The new laser welding machine…

welding of impellers, kettles, handles, and other components in the hardware industry, as well as complex stamping and casting parts. engine cylinder gasket welding, hydraulic tappet sealing welding, spark plug welding, filter welding, and so on. Medical equipment welding, stainless steel seals, and structural parts of medical equipment industry: welding of solid state relays for…

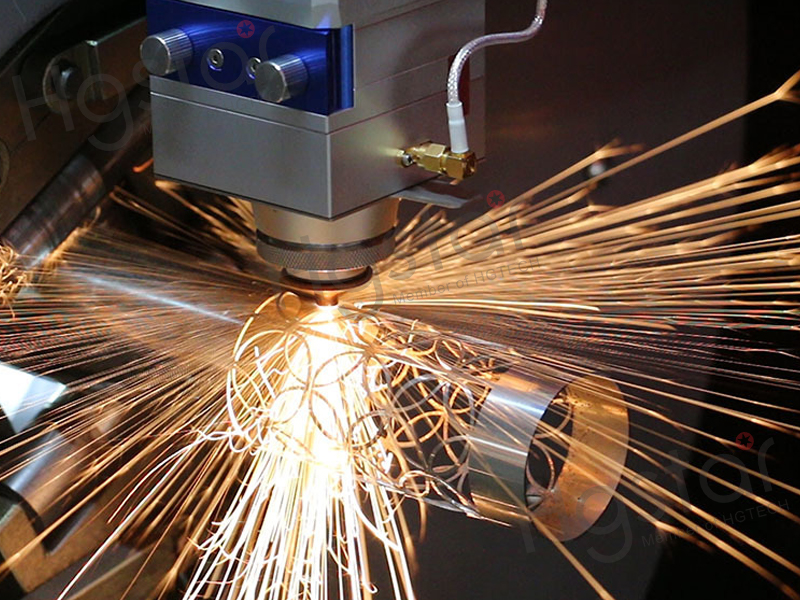

For the zero-tailing pipe laser cutting machine, these are non-existent. In theory, the length that can be cut will achieve zero-tailing cutting, greatly increasing the pipe’s utilization rate. The zero-tail pipe laser cutting machine can perform three chucks simultaneously to assist with clamping and has the benefits of fast cutting speed, high processing accuracy, and…

Any new technology that is easily recognized by the majority of people must have characteristics that the old technology lacks. The laser pipe cutting machine should then have specific characteristics and advantages over traditional pipe processing equipment. Let’s take a look at its features and benefits! 1. Flexibility The laser pipe cutting machine can cut…

Metal furniture is becoming more common in everyday life. Metal furniture, whether in the home or in public places, is attractive, long-lasting, and simple to clean. It has gradually replaced traditional wooden furniture and has become the new home favorite. Metal tube laser cutting machines, or laser pipe cutting machines, are commonly used in the…

1. If the final appearance of the aluminum material is unimportant, the aluminum material can be painted black, which effectively reduces the reflectivity of the aluminum material to the laser, allowing the aluminum material to be cut more easily. 2. If funds are available, a larger laser can be replaced. The light reflectivity of common…

Increase in the plate’s ultimate cutting thickness: Carbon steel plates up to 80mm thick and aluminium plates up to 100mm thick can be cut with today’s high-power aluminium laser cutting machines. The data presented above are all 20000W power cutting data. The plate cutting thickness will continue to increase as laser cutting technology improves. 6000W…

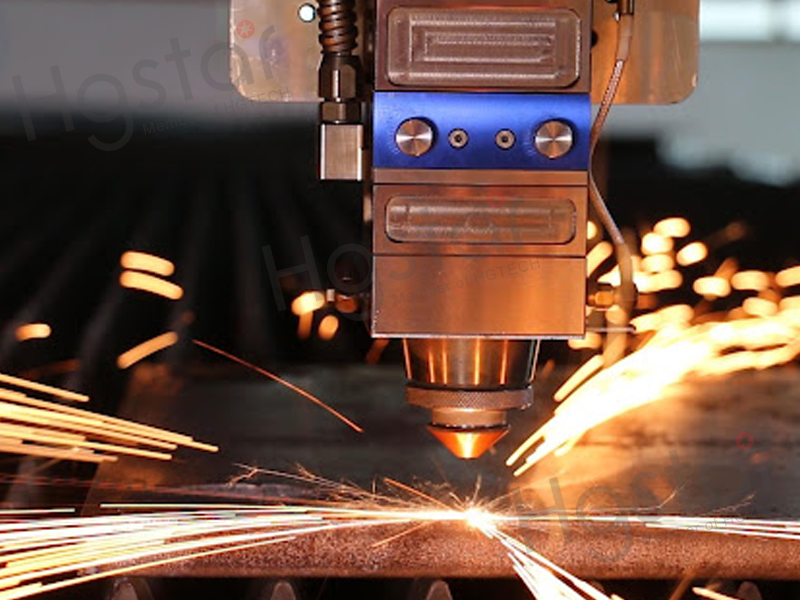

The laser cutting system employs a laser focusing system to direct high-energy laser light onto the material’s surface. The laser energy is absorbed by the material, which causes it to be locally heated above its melting point. Simultaneously, the coaxial high-pressure gas or generated steam blows the molten metal away, leaving cavities on the material’s…

CNC Laser Cutting Machine Lens Why Will Be Dirty When the laser cuts the material, the working surface emits a large amount of gas and splashes, causing the CNC laser cutting machine lens to be damaged. When contaminants land on the surface of the lens, energy from the laser beam is absorbed, resulting in a thermal…

.jpg)