News

Advantages Of High-Power Aluminium Laser Cutting Machine

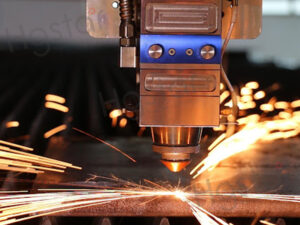

Fiber laser cutting machines are currently a relatively common piece of metal processing equipment. High-power fiber laser cutting machine is the general trend in terms of market competition and user practical application.

The market for aluminium laser cutting machines was dominated in the early years by low-power machines such as 500W, 750W, and 1000W, which were gradually replaced by 3000W and 6000W. Until now, 12000W, 15000W, and 20000W have been the industry standard for large metal processing.

Why can high-powered aluminium laser cutting machines gradually replace low/medium power machines? What are its benefits?

Increase in the plate’s ultimate cutting thickness:

Carbon steel plates up to 80mm thick and aluminium plates up to 100mm thick can be cut with today’s high-power aluminium laser cutting machines. The data presented above are all 20000W power cutting data.

The plate cutting thickness will continue to increase as laser cutting technology improves. 6000W power, when compared to low and medium power, can cut carbon steel with a thickness of 25mm and aluminium with a thickness of 20mm. The maximum cutting thickness has been greatly increased.

The speed of sheet metal processing is increased by multiples:

In the actual application of a aluminium laser cutting machine, the cutting speed of various materials is the deciding factor. In the processing of medium and low thickness plates, the aluminium laser cutting machine offers significant advantages.

An increase in cutting speed directly leads to an increase in economic benefits. Using the current common 12000W vs. 6000W as an example, cutting 16mm stainless steel plates is the same.

The 6000W power cutting speed is only 0.6m/min, while the 12000W power cutting speed is 2.4m/min. In comparison, production efficiency can be improved concurrently. This type of manifestation will become more visible in thick plate cutting about three times.

The cutting process is more diversified and developed:

The increased power of the aluminium laser cutting machine causes an increase in sheet thickness as well as an increase in cutting speed. As laser power increases, new tricks in the laser cutting process may emerge.

High-speed bright surface cutting technology, for example, adjusts related parameters using a combination of small nozzles, low air pressure, and high power to produce workpieces with a smooth section and a smaller taper.

These more accurate products can better meet the needs of customers. The market for high-power aluminium laser cutting machine has gradually opened up in response to this demand.

The samer pro series aluminum laser cutting machine from HGSTAR offers faster cutting speed and perfect cutting accuracy. Equipped with exchange platform to improve cutting efficiency.