Lithium battery PACK modules require certain welding conditions for laser welding. 1. When assembling or welding, prevent short circuits. 2. During the welding process, the cell body’s influence on temperature should not be greater than 60 degrees Celsius. 3. The welding area’s minor oxidation area has no impact on the tabs’ conductivity. 4. Mass production…

Laser has become the copper-aluminum welding of power batteries, and the only technology that can weld electroplated nickel to copper materials, due to its advantages of focused energy, high welding efficiency, high processing precision, and big weld seam aspect ratio. A wise choice of welding methods and procedures will have a direct impact on the…

Xi Jinping, general secretary of the CPC Central Committee, president and chairman of the Central Military Commission, emphasized during a visit to Wuhan City in Hubei Province on the 28th that scientific and technological self-reliance and self-improvement is the foundation of national strength and security. We must complete, accurate and comprehensive implementation of the new…

There are several elements that influence laser welding quality, some of which are exceedingly dynamic and unstable. The practicality of laser welding technology, an important issue of industrialization, is related to how to correctly set and control these parameters so that they can be controlled within a suitable range in the high-speed continuous laser welding…

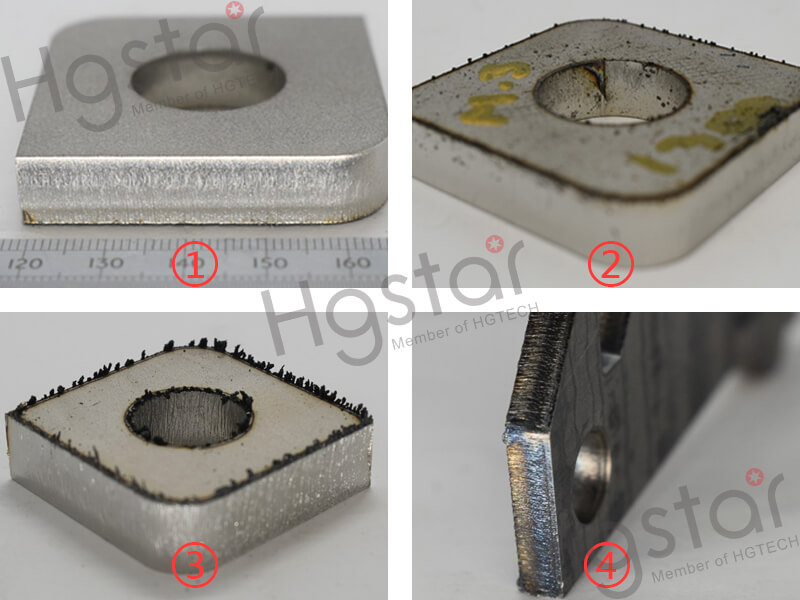

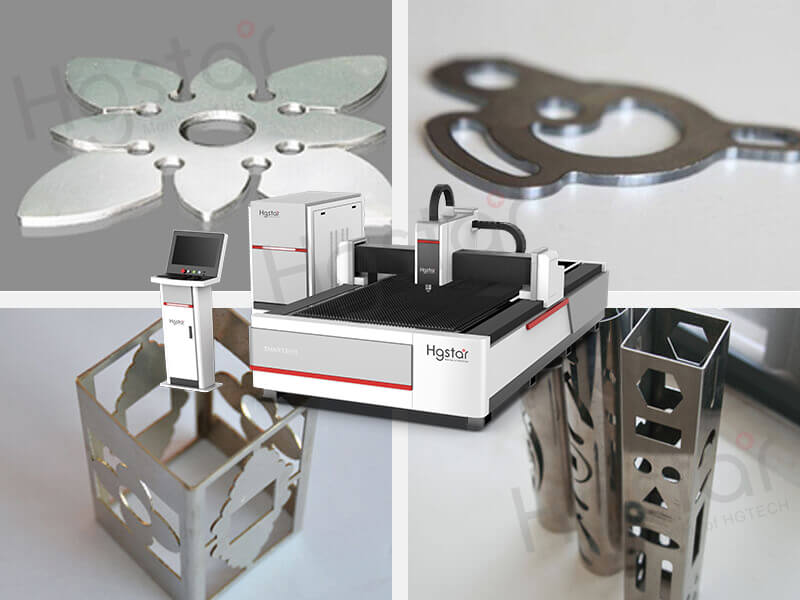

Are you planning to purchase a laser cutter, but are doubting which one is best for stainless steel? This page will tell you the key factors to consider when purchasing a laser cutting machine for stainless steel as well as the cost. 1 Stainless Steel Laser Cutting Speed The cutting speed is determined by the…

the influence on the thermal motion of the molecules can be avoided, and the surrounding material will not be thermally affected. Laser “cold working” can reduce melting and heat affected zone, resulting in less microcracks in material. Picosecond laser wire cutting technology is used to cut the whole plate of the mobile phone camera protection…

Is it possible to cut aluminum with a laser? Aluminum can be cut and engraved using industrial lasers. The majority of lasers that can cut through steel plates are high power capacity CO2 lasers. When compressed gas technology is used, metals such as stainless steel and aluminum can be cut with a laser. How long…

1. The metal laser cutter features a gantry-type single-side double-drive structure, an imported high-precision reducer, a gear rack, and a linear guide, as well as smooth transmission, fast acceleration, and bit precision. 2. The entire welded structure is used for both the bed and the moving beam. The welding process can be completely eliminated after…

What does smart manufacturing look like in your mind? Are tens of thousands of products being processed orderly on unmanned production lines? Or do operators manage remotely, precisely allocate materials, and grasp the rhythm of production? “Black light factory” “digital workshop”… These are all intelligent manufacturing, and intelligent manufacturing is much more than that. How…

It is time to say goodbye to traditional welding method. Traditional welding is difficult to operate, the efficiency of the welding is unsatisfied and the the work-piece is easily deformed. The equipment is costly to purchase and maintain. In addition, the radiation, fumes and harmful gases are also harmful to the health of the workers. Nowadays…