News

New Product Launch: HGLaser Makes a Grand Appearance at the China International Machine Tool Show

China International Machine Tool Show · CIMT

On April 21, the China International Machine Tool Show opened grandly in Beijing. HGLaser showcased two groundbreaking intelligent devices centered around high-end manufacturing, demonstrating its strong capabilities in independent research and development. The solutions presented include “Laser + Intelligent Manufacturing” for industries such as automotive manufacturing, sheet metal processing, and shipbuilding and bridge construction.

April 21-26, 2025

China International Exhibition Center (Shunyi Hall) · Beijing

Booth No.: E3 Hall B011

1.Star Product Upgraded for Debut

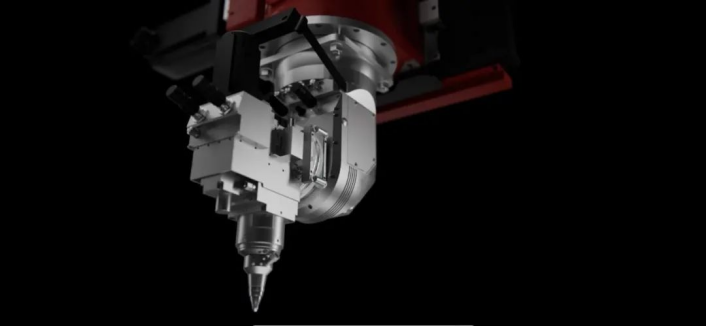

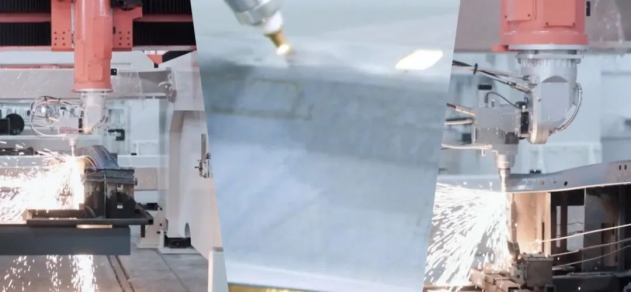

Fifth-Generation Intelligent 3D Five-Axis Laser Cutting Equipment

HGLaser’s Fifth-Generation Intelligent 3D Five-Axis Laser Cutting Machine makes its global debut, leading the global laser equipment industry with multiple groundbreaking technologies. The key core components of this equipment are 100% independently controllable, and its processing efficiency meets the world’s top standards. It perfectly addresses the requirements for cutting holes and trimming on curved workpieces.

Remote Operation and Maintenance System

Integrated with full-lifecycle equipment management, this system enables efficient cross-regional and group-level coordination through intelligent monitoring, automated work order processing, and a preventive maintenance framework.

Precision Enhancement System

Breaking through foreign technological barriers, our self-developed intelligent compensation technology achieves micron-level dynamic error compensation, with application scenarios covering the entire field of precision manufacturing.

Intelligent AI Interaction System

Achieving millisecond-level voice response for fully automated intelligent interaction, the digital assistant helps users complete machining, operation, and daily maintenance of CNC machines.

Intelligent Programming System

Effectively reducing burr rates at internal and external corners, controlling average burr height, and significantly improving programming efficiency for complex workpieces, enabling beginner-friendly expert-level operation.

2.High-end Manufacturing New Product Debut

Six-Axis Laser Micro-Hole Processing Equipment for Complex Surfaces

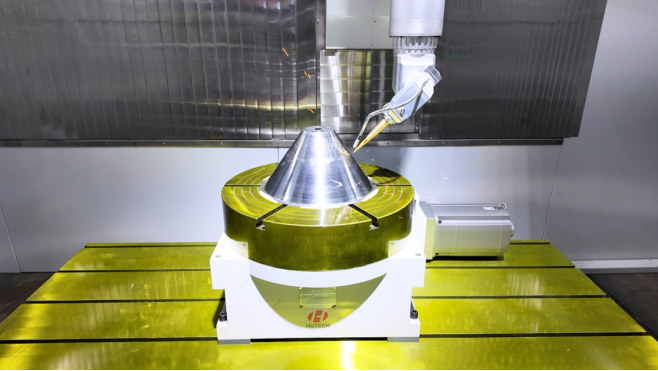

Complex Surface Six-Axis Laser Micro-Hole Processing Equipment

This equipment is a key component in the engine manufacturing industry chain for the aerospace, aviation, and shipbuilding sectors. Its development addresses the core processing challenges of aerospace engines and gas turbines.

Remote Operation and Maintenance System

To meet the application demands for high-quality and efficient processing of film cooling holes in the combustion chambers of aircraft engines, two critical scientific issues are researched: multi-axis linkage with laser pulse output collaborative control, and the stability regulation of quasi-continuous laser processing technology.

Precision Enhancement System

This system has overcome key technologies such as quasi-continuous laser output optical field control based on spatiotemporal shaping, high peak power quasi-continuous fiber laser mode control, nonlinear multi-objective redundant axis machine tool trajectory planning, and special-shaped hole laser processing technology and inspection.

Focusing on Global Laser Processing Trends, HGLaser In response to high-end manufacturing, HGLaser enhances technological autonomy and control through independent research and development, leading innovation to provide advanced laser + intelligent manufacturing solutions.

The China International Machine Tool Exhibition will be held until April 26.

HGLaser cordially invites you to visit us!

China International Exhibition Center (Shunyi Hall), Beijing

Booth No.: E3 Hall B011