Three Chuck Tube Laser Cutting Machine

Model: Talos6536/6565/9035/9065 Series

Category: Laser Tube Cutting Machine

Brand Name: HGSTAR

Laser power: 1000W-6000W

Stock: 20 units in stock

Uses: A laser tube cutter will replace mechanical drilling, milling, sawing, punching or cleaning of burrs and other processing procedures that require different metal pipe cutters and hard tools, and realize the cutting, chamfering, and cutting of complex pipe structures. Conditionally, zero-tail cutting can be realized as well, depending on the cutting size of the workpiece and the specific cutting process.

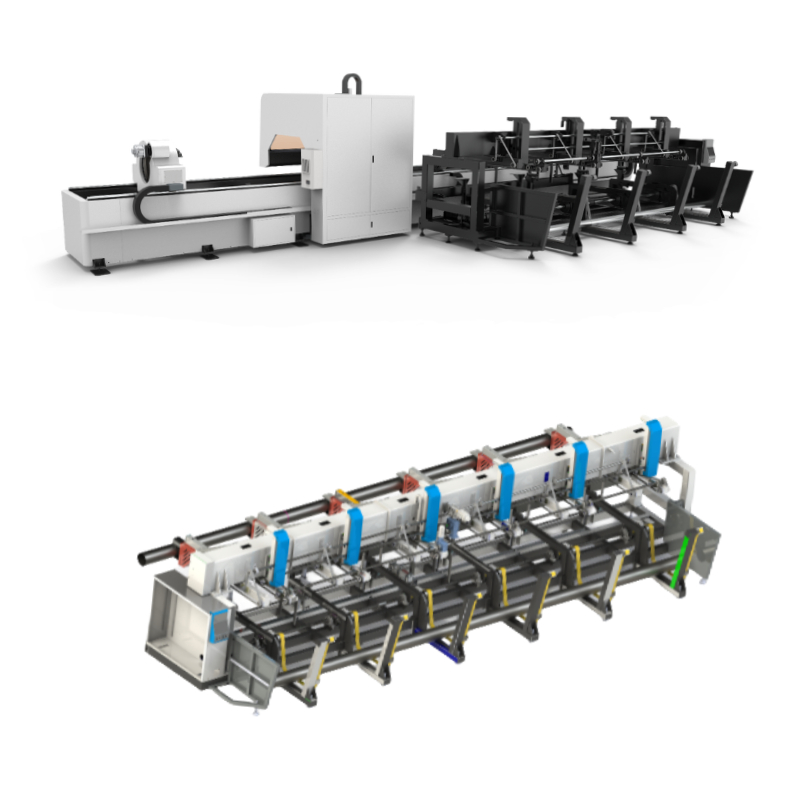

SMART Talos6535/6565/9035/9065 three chuck cutting machine is manufactured by HGSTAR according to international export standard. This series of equipment is the preferred model for the metal tube processing industry. The machine has high precision, processing accuracy with higher photoelectric conversion efficiency, strong anti-high capability and stability of lasers. Follow-up unloading device and unloading conveying system make the cutter more efficient.

Fiber Laser Tube Cutting Machine Parameter

| MODEL | SMART Talos 6535/6565 | SMART Talos 9035/9565 |

|---|---|---|

| Pipe loading length | 6500mm | 9000mm |

| Laser Source | Fiber & 2000W – 6000W | |

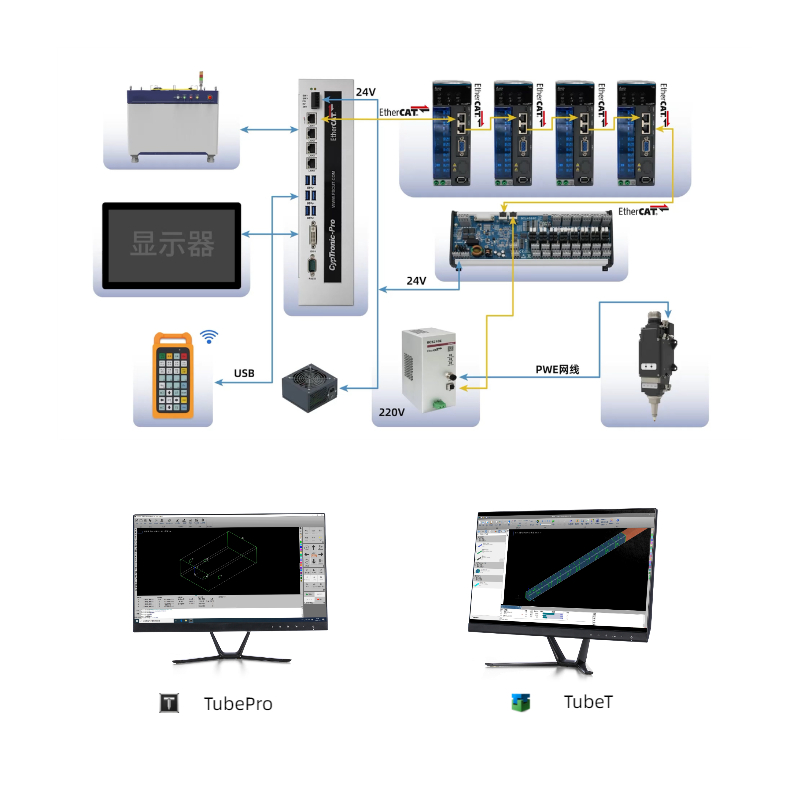

| CNC System | FSCUT 5000 | |

| Chuck diameter | Φ20mm – Φ230 / Φ20mm – Φ280 / Φ20mm – Φ350 | |

| Position Accuracy (X and Y axis) | 0.05mm | |

| Reposition Accuracy (X and Y axis) | 0.03mm | |

| Power Supply Requirement | 380V 50/60Hz 3PH | |

LaserTube Cutting Machine Video

Features of Laser Tube Cutting Machine

Durable, Accurate, Effective

The welded construction guarantees remarkable stiffness and accuracy, allowing for long-term use without deformation.The inclusion of an automatic loading and unloading device significantly enhances the machine’s productivity.

Fast, Reliable, Stable

Pneumatic chuck

Double rows of rollers for effective correction of pipe bending with the ability of precise centering, fast automated processing.High support bearing stability with integral support base structure, highly rigid long cantilever structure, and optional clamping of various profiles.

Accurate and Logical

Three chuck processing

Able to move along the Y-axis direction and rotate synchronously.

Under the logical system, pull-type cutting can be cpmpleted accompanied with greater cutting accuracy, and zero-tail cutting conditionally.

Adaptable and Accurate

Bed follower centering bracket

Fully automatic servo-following control allows the great adaptability to pipe rotation radius change, and prevent the pipe from sagging.

The system chuck and clamp the pipe during the process, thus improving the processing accuracy.

Automated and Flexible

Follow-up Unloading Device

The system not only will automatically control the material receiving and unloading action, realize waste screening, but flexibly adapts to the length of workplace.

Unloading Conveying System

Fully mobile structure, intelligent completion of receiving and transporting cut pipes.

Intelligent and Professional

CNC Control System FSCUT5000

Rich application assistance functions with professional operating software (TubePro) and nesting software (TubeT).

Higher quality and Efficient

Standard Cutting Head

Self-focusing fiber optic cutting head,

Multi-protection lens, drawer type mirror holder

Improved optical setup and special airflow design

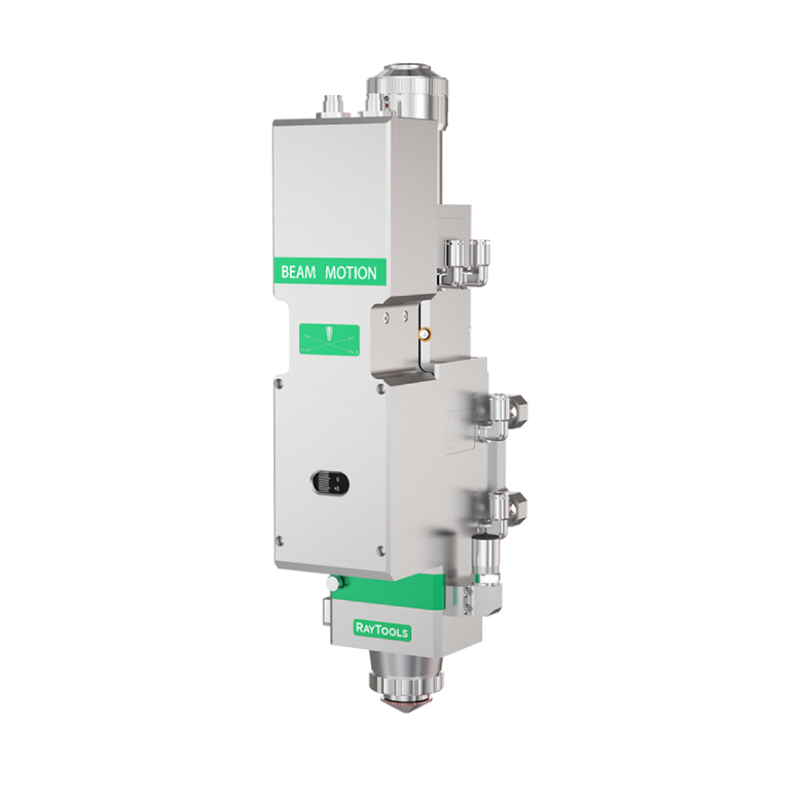

Bevel cutting (Optional)

Auto focus fiber cutting head

Multi-protection

Great optical configuration and efficient airflow design

Stable rotating mechanism, can achieve ±45° bevel cutting

Option: Semi-Auto or Auto loading system

| system | Semi-Auto loading (Top) | Auto loading (Bottom) |

|---|---|---|

| Manually lift pipes to loading rack; Automatically sorting, measuring length, loading and transporting the pipes to cutting head. |

||

| Unit Weight | ≤200KG | ≤240KG |

| Loading Capacity of the Silo | ≤3T | ≤3T |

| Applications | Rectangular, Round, Square and OB tubes | Pipe whose cross section is axisymmetric |

| Other | Modular design, servo drive, independent control system. | |

Are you interested in our product?

Please feel free to contact us, we would like to help you with advice and support.

| model | SMART Talos |

|---|

Be the first to review “Three Chuck Tube Laser Cutting Machine” Cancel reply

You must be logged in to post a review.

Reviews

There are no reviews yet.