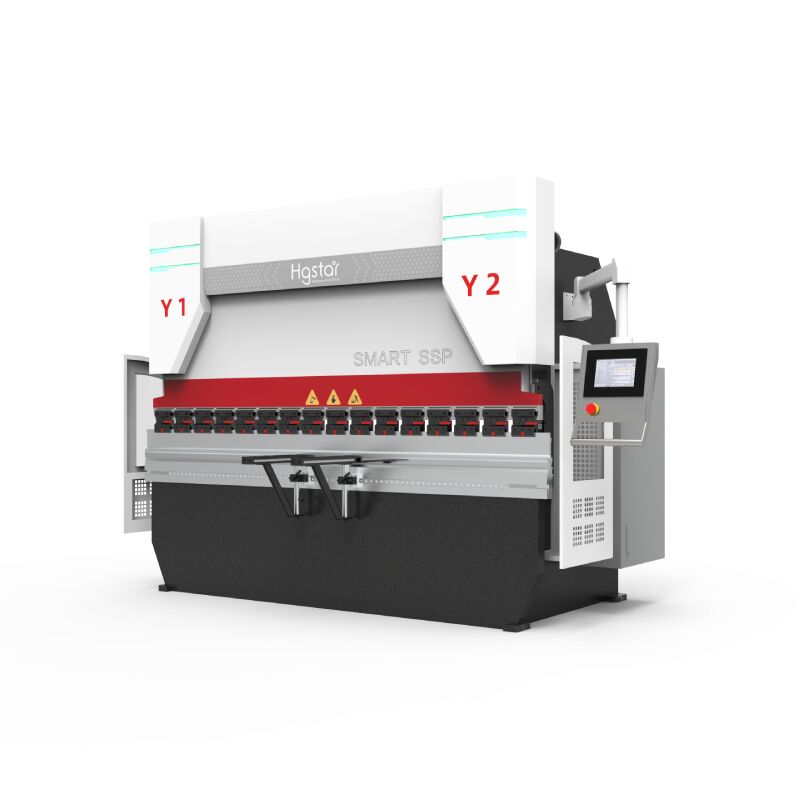

HG-SSP 135/3200 CNC Bending Machine

Model: HG-SSP 135T/3200

Category:CNC bending machine

Brand Name: HGSTAR

Laser power: 13.2KW

CNC Bending Machine Video

Machine configuration:

- Y1-Y2-X-R-V five-axis CNC

- Equipped with the special CNC system for DA53T bending machine from DELEM, the Netherlands

- Equipped with German BOSCH-REXROTH high-performance proportional servo hydraulic system

- Configure the grating ruler of SPAIN FAGORcompany

- Configure the oil pump of SUNNY, USAcompany

- The mechanical downward inclined block deflection compensation worktable controlled by the DNC system

- The back gauge is equipped with high-performance servo motor and ball screw

- A set of standard molds

| No | Configuration | Numerical value | unit | Remark | |

| 1 | Nominal pressure | 1350 | KN | ||

| 2 | Foldable plate width | 3200 | mm | ||

| 3 | Slide stroke | 200 | mm | ||

| 4 | Maximum opening height | 420 | mm | ||

| 5 | Column spacing | 2700 | mm | ||

| 6 | throat depth | 400 | mm | ||

| 7 | Fast down speed | 160 | mm/ s | ||

| 8 | Return speed | 130 | mm/ s | ||

| 9 | Working speed | 10 | mm/ s | ||

| 10 | Main motor power | 11 | Kw | servo motor | |

| 11 | CNC system | DA53T | Netherlands | ||

| 12 | X-axis travel of rear stopper | 500 | mm | ||

| 13 | Number of control axes | 4+ 1 Axis (Y1 、Y2 、X 、R+V) | |||

| 14 | Machine tool accuracy | Slider repeat accuracy | ≤±0.01 | mm | |

| 15 | Slide positioning accuracy | ≤±0.02 | mm | ||

| 16 | Workpiece straightness | 0.3 / m | mm | ||

| 17 | Bending angle error | <±30 | ′ | ||

| 18 | Raster scale resolution | 0.005 | mm | ||

| 19 | Rear retaining material | X-axis travel | 500 | mm | |

| 20 | X-axis speed | 200 | mm/s | ||

| 21 | positioning accuracy | ±0.05 | mm | ||

| 22 | Repetitive positioning accuracy | ±0.015 | mm | ||

| 23 | Machine wight | 10 T | T | ||

| 24 | Machine diamentions | L 3500 / W 1580 /H 2500 | mm | ||

Technical parameters

| No. | Project | Qty | Remark |

| 1 | Control System | 1 Set | Netherlands DELEM DA53T System |

| 2 | Servo Motor And Drive | 1 Set | Nanjing Eston |

| 3 | Hydraulic Pump | 1 Set | SUNNY, USA |

| 4 | Hydraulic Valve | 1 Set | BOSCH- REXROTH |

| 5 | Ball Screw | 1 Set | Taiwan |

| 6 | Linear Guide Rail | 1 Set | Taiwan |

| 7 | Connector | 1 Set | German |

| 8 | Seal Ring | 1 Set | Japan Nok Or Germany |

| 9 | Grating Ruler | 1 Set | Spain FAGOR |

| 10 | Main Electrical Components | 1 Set | Schneider |

| 11 | Cylinder | 1 Set | Jining Taifeng |

| 12 | Servo Main Motor | 1 Set | Nanjing Eston |

Product Details Display

The main oil cylinders on both sides are synchronously controlled by the electro-hydraulic servo valve imported from Germany and the grating ruler of FAGOR in Spain,The feedback is accurate, and the slider operates accurately, so that the bending accuracy and the repeated positioning accuracy of the slider are high.

V-axis compensation. Solve the influence of the deformation of the slider during the bending process on the quality of the workpiece. The compensation amount is automatically controlled by the numerical control system.

The X-axis rear retaining frame is composed of left and right guide rail seats, beams, adjusting seats, supports, adjustable supports, seat plates, adjusting seats, adjusting screws, retaining fingers and other parts. The control of X-axis movement is realized through the servo motor of X-axis.

The rear stopper of R-axis is composed of guide rail seat, R-axis motor and reducer, and drives the cross beam along the linear guide moves up and down. The control of the R-axis movement is realized by the servo motor of the R-axis.

Size and pressure change, feedback the monitoring signal to the driver for rapid processing and correction, which is a closed-loop non-overflow first

Enter the control method. The advantages are energy saving, low oil temperature, environmental protection and high efficiency.

Related Projects

Related Stories

Are you interested in our product?

Please feel free to contact us, we would like to help you with advice and support.

| model | CNC Bending Series |

|---|

Be the first to review “HG-SSP 135/3200 CNC Bending Machine” Cancel reply

You must be logged in to post a review.

Reviews

There are no reviews yet.