News

HGTECH partners with Swiss company Synova to jointly explore new market opportunities in Laser MicroJet® technology.

On April 22, HGTECH’s core subsidiary HGLaser and Swiss company Synova officially announced the establishment of a joint venture in Beijing. The two parties held in-depth discussions on implementing the joint venture’s strategic roadmap and deeply integrating Laser MicroJet® applications, jointly exploring prospects for future cooperation. The founding ceremony was attended by Mr. Deng Jiake, General Manager of HGLaser, and Dr. Bernold Richerzhagen, Founder of Synova.

Laser MicroJet® Technology

Conventional laser cutting faces significant challenges when processing advanced materials such as carbon fiber reinforced composites, ceramic matrix composites, silicon carbide, ceramics, and diamonds. These challenges include process instability, severe thermal damage, and rough cut surfaces, which, to a certain extent, hinder the rapid development of high-end manufacturing.

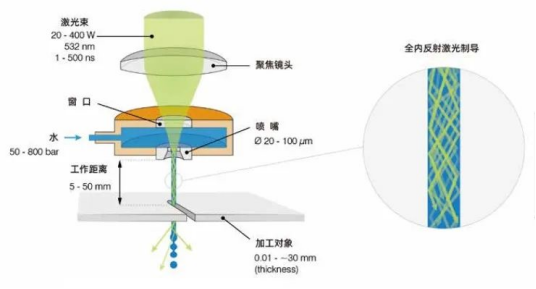

Laser MicroJet® is a precision machining technology characterized by low thermal damage, burr-free edges, and high aspect ratio cutting. It operates by coupling a high-power pulsed laser beam into a water jet, which then guides the laser to the workpiece surface for processing. The high-power laser is delivered via fiber coupling, focused through a lens, and directed through a nozzle located at the base of a flattened water chamber. The resulting cylindrical water jet both confines and guides the laser beam to the surface of the material, enabling precise and clean machining.

This unique method of coupling a laser beam with a water jet produces kerfs that are parallel to the cutting surface, ensuring exceptional machining precision. The process also provides efficient cooling and cleaning of the machining zone, eliminating the need for laser focusing and standoff distance control during operation. These advantages make Laser MicroJet® particularly well-suited for the fabrication of critical components in industries such as aerospace, semiconductors, and medical devices.

As the pioneer and global leader in Laser MicroJet® (LMJ) technology, Synova has dominated this specialized market since the technology was first introduced in 1997. Its innovation bridges the gap between conventional dry laser processing and mechanical machining, offering a unique solution where high precision and minimal thermal damage are critical. The technology is particularly indispensable in sectors such as semiconductors, medical devices, and consumer electronics, where ultra-precise, low-damage processing is essential.

As a pioneer and leader in the industrialization of laser applications in China, HGLaser is a globally recognized authority in laser processing solutions. The company has built a comprehensive product portfolio covering laser cutting, welding, cleaning, and more. With a strategic focus on laser-based intelligent equipment, precision measurement systems, automated production lines, and smart factory development, HGLaser delivers core solutions to high-end manufacturing sectors such as automotive and shipbuilding, while providing integrated solutions for Intelligence Manufacturing.

The establishment of this joint venture marks a deep integration of Synova’s three decades of technological expertise with HGLaser’s strengths in industrialization and globalization across intelligent equipment and advanced manufacturing. This collaboration will accelerate the evolution of Laser MicroJet® technology toward greater automation and intelligence, driving the growth of emerging industries and advancing new quality productive forces.