Uncategorized

Unlock the Power of Precision: CO₂ Laser Glass Cutting Revolutionizes Industries

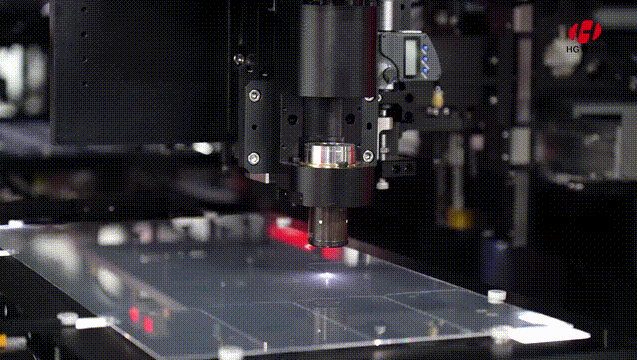

In the fast-paced manufacturing world, industries are always looking for ways to enhance efficiency, precision, and product quality. When it comes to cutting glass, one technology stands out: CO₂ laser glass cutting. This cutting-edge method is changing the way we work with glass across construction, automotive, and consumer electronics, offering precise cuts with minimal waste and damage.

What is CO₂ Laser Cutting?

CO₂ laser cutting uses carbon dioxide gas as the laser medium to produce infrared laser light at a wavelength of 10.6 microns, which is easily absorbed by glass. Unlike traditional mechanical cutting methods, CO₂ lasers vaporize the glass directly at the cutting point with a focused beam, leaving smooth, clean edges without causing mechanical stress or cracking.

The technology’s non-contact nature minimizes the risk of damaging the glass or equipment wear, making it ideal for precise and high-quality cutting. It allows for intricate designs, even in high-volume production, while maintaining consistency.

Key Benefits of CO₂ Laser Cutting

CO₂ laser cutting offers several distinct advantages:

1.Precision: Whether it’s for architectural glass or automotive windows, CO₂ lasers ensure clean, smooth cuts that are virtually free of chips or cracks.

2.Efficiency: Faster cutting speeds compared to traditional methods allow manufacturers to increase productivity and reduce lead times.

3.Versatility: This technology works well for a wide range of glass types, from standard to tempered and optical glass, meeting various industry needs.

4.Reduced Thermal Impact: The laser’s small heat-affected zone ensures glass remains intact, preserving both the appearance and strength of the material.

Applications Across Industries

CO₂ laser cutting is widely used in several sectors:

- Construction: CO₂ laser cutting enables precise glass for curtain walls, windows, and facades, enhancing both design flexibility and safety.

- Automotive: It ensures accurate, high-quality glass for windshields, sunroofs, and side windows, helping manufacturers meet modern design and safety standards.

- Consumer Electronics: For mobile devices and touchscreens, CO₂ laser cutting guarantees the precision needed for thin, durable glass components.

Future Outlook

As urbanization grows and the demand for innovative designs increases, the need for CO₂ laser glass cutting will continue to rise. With advances in technology making lasers more affordable, smaller manufacturers are also adopting this cutting-edge method. The future of CO₂ laser cutting looks bright as it drives manufacturing forward with precision, speed, and versatility.