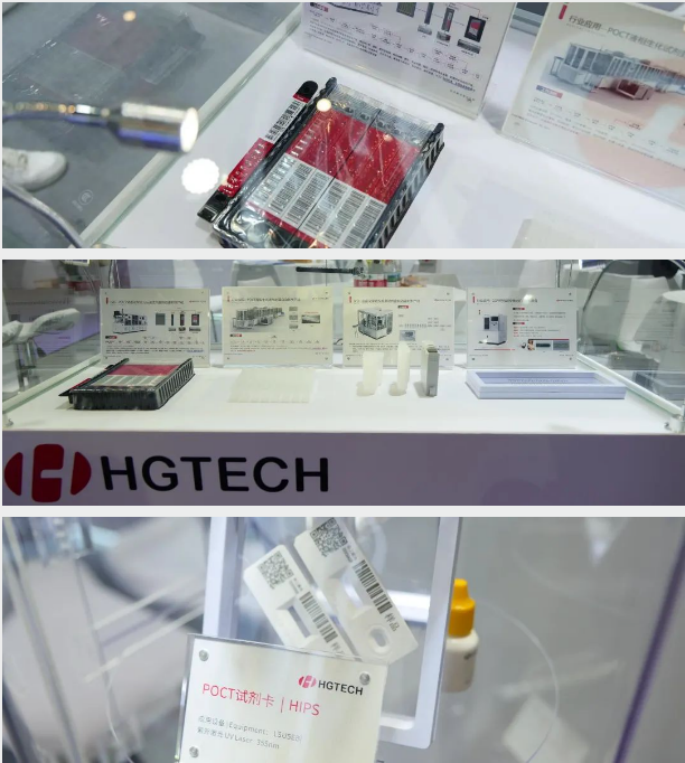

On March 22, the 22nd China International Laboratory Medicine and Blood Transfusion Instruments and Reagents Expo (CACLP 2025) grandly opened in Hangzhou. HGTECH showcased its comprehensive “Laser + Intelligent Manufacturing” solutions for the in vitro diagnostics (IVD) sector.

Focusing on the needs of the IVD industry and leveraging its expertise in laser technology and automation system integration, HGTECH reaches new heights in intelligent manufacturing. It delivers comprehensive, efficient, and intelligent manufacturing solutions for the life sciences and IVD industry.

Precision · Efficiency · Power

Intelligent Equipment for the IVD Industry

The in vitro diagnostics (IVD) industry is moving towards precision, automation, and intelligence. To address the core challenges in the packaging process of IVD reagents, HGTECH has developed intelligent equipment for plastic welding of IVD reagent kits and microfluidic chips. The products feature minimal deformation and excellent packaging consistency.

For the medical industry, using fiber optic homogenization technology, the system outputs a rectangular processing light spot, paired with a mask plate, enabling rapid welding between microfluidic plastic components. It addresses the issues of channel contamination, slow welding speed, and low welding strength in the microfluidic chip welding process.

Advantages:

High Efficiency: Dual workstations enable continuous production; line-shaped light spot and welding speed are more than 3 times faster than traditional methods.

High Yield: The spot DOE shaping technology ensures a spot consistency of over 95%; the closed-loop temperature monitoring system has an accuracy of ±2.5°C, ensuring consistent welding quality; the collapse value monitoring system has an accuracy of ±0.01mm, ensuring good welding strength and air-tightness.

Good Compatibility: Supports quick product changeover, compatible with different welding tracks and line width requirements; customizable heating parameters for different product areas to meet various welding needs.

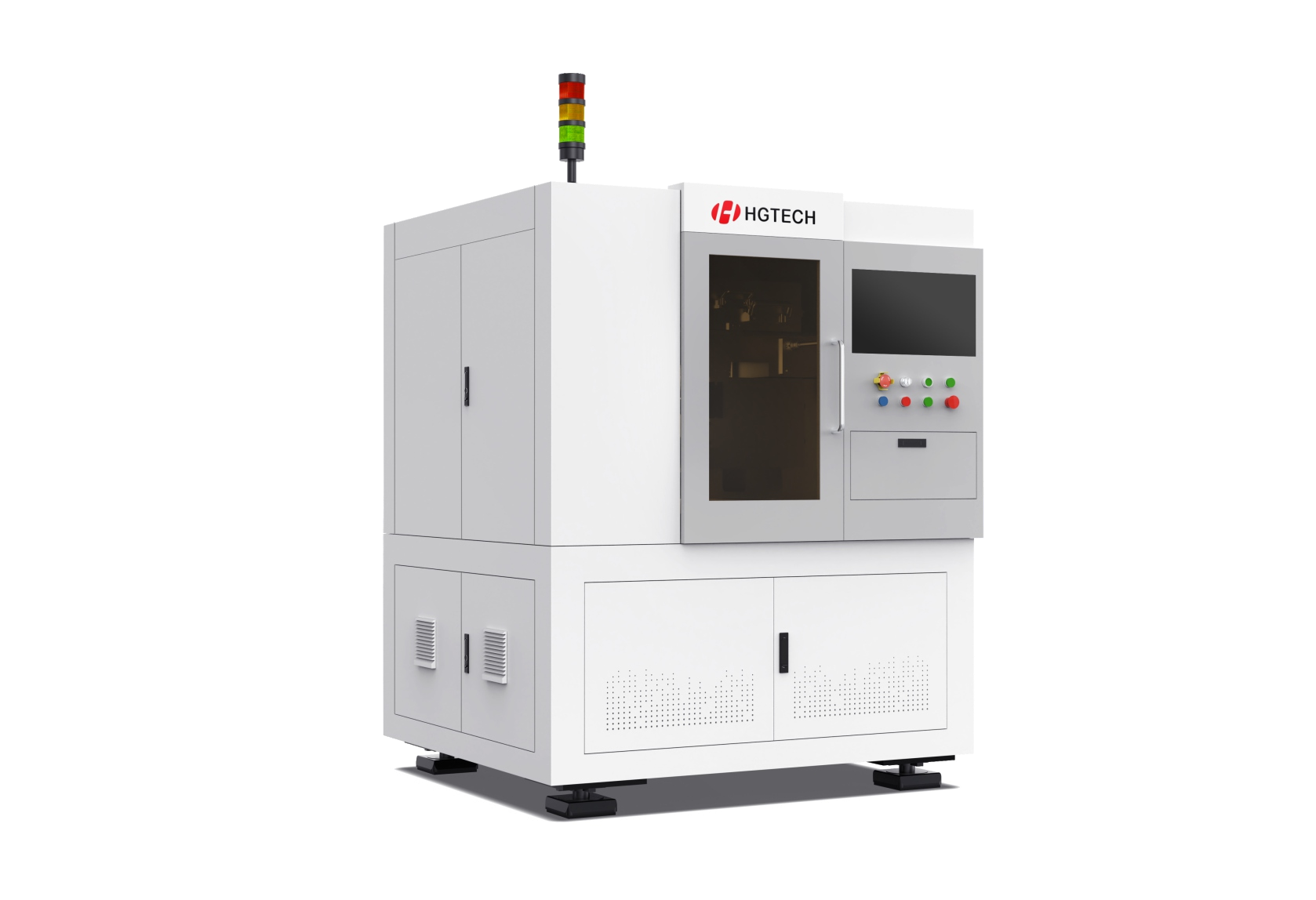

For implanted biosensor chip electrodes and wearable medical product chips, high-precision cutting is achieved through visual positioning, ensuring no yellowing, blackening, or color discrepancies on the appearance. The surface is free from dust, with neat edges and high processing efficiency. This solves the challenges of high-precision, non-destructive, and irregular shape processing.

Advantages:

High Quality: The cutting edges are neat, with no excess material, burrs, or melted edges.

High Precision: Femtosecond laser is equipped with high-precision galvanometers and 3D contour-following fixtures, ensuring stable high-precision processing.

Pollution-Free: A smoke and dust recovery system is used, preventing dust pollution.

Autonomous and Controllable: Core light source technology is mastered, with both software and hardware being independently controllable.

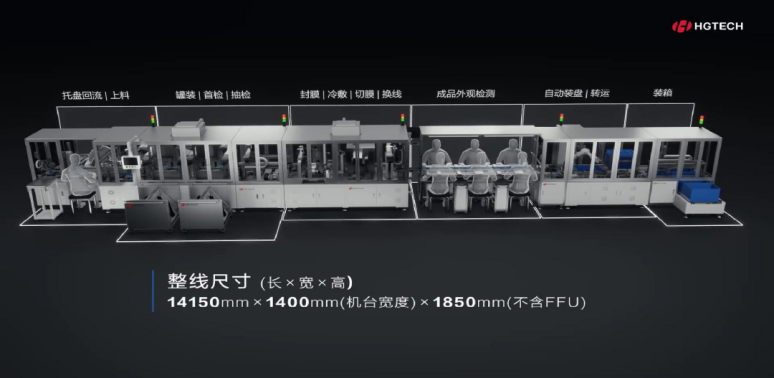

POCT Liquid Phase Biochemical Reagent Encapsulation Automation Production Line

The system integrates high-precision automatic filling, automatic sealing, laser automatic film cutting, finished product inspection, robotic tray loading, and finished product packing functions. It is used for the filling production of POCT diagnostic reagents for IVD companies. The high level of automation ensures precise quality control, scientific production, and significant improvements in quality, cost reduction, and efficiency.

Advantages:

Reagent Filling Range: 50-500ul

Accuracy: ±5ul for a 50ul filling volume

Production Line Speed: ≥40 pcs/min, UPH ≥2000 pcs/h

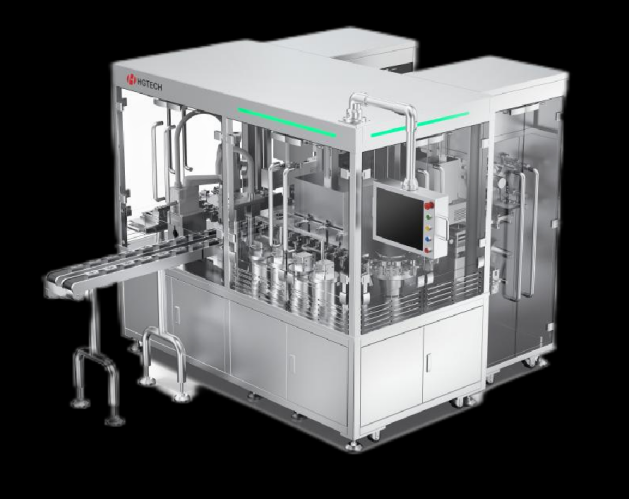

Automated Filling Production Line for Immunochemiluminescent Detection Reagent Kits

This production line integrates material feeding, weighing & filling, film sealing & inspection, and finished product unloading processes to achieve high-precision, high-efficiency automated filling. It includes formula management, easy changeover, no cross-contamination, compatibility with multiple projects, safety and stability, and user-friendly operation. It is seamlessly connected with the factory’s MES for smart manufacturing and digital management, ensuring high efficiency, precise quality control, scientific production, and significant improvements in quality, cost reduction, and efficiency.

Advantages:

Capacity: 25 pcs/min (single station), 50 pcs/min (dual stations)

UPH: 1500 pcs/h (single station), 3000 pcs/h (dual stations)

2025 CACLP

Medical + Laser “Intelligent” Manufacturing

Building on deep expertise in laser technology and research in the medical industry, HGTECH continues to empower the sector with laser “intelligent” manufacturing. It is committed to becoming the “preferred brand for laser manufacturing in the medical device industry,” driving industrial innovation and upgrading for high-quality development.