1. Improved Efficiency

Robotic automated loading and unloading systems are characterized by high speed and high precision, capable of completing a large number of repetitive loading and unloading tasks in a short period of time, significantly enhancing efficiency.

2. Guaranteed Product Quality

Automated loading and unloading systems ensure the stability and consistency of workpieces through precise positioning and control, reducing the impact of external factors on product quality.

3. Enhanced Workplace Safety

Compared with hazardous manual operations, automated loading and unloading systems reduce the risks associated with workers’ exposure to dangerous equipment and materials, thereby improving safety.

4. Reduced Costs

Automated loading and unloading systems greatly reduce reliance on labor, thereby decreasing labor costs. Additionally, these systems have the capability to operate continuously for 24 hours, enhancing production line utilization and operational efficiency.

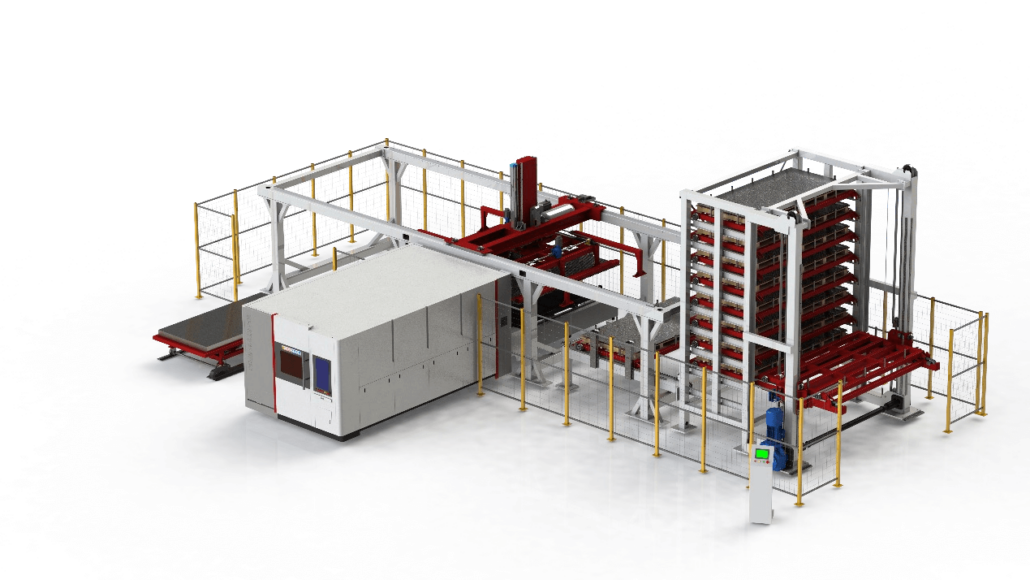

Smart HCR

Smart HCR automatic sheet metal loading and unloading

Sheet metal size: min1*0.6m, max4*2m

Sheet metal thickness: 1~15mm (3015)

Maximum weight of a sigle sheet metal: 500kg

Features: This sheet metal laser automation unit has a simple structure and low cost, and is suitable for enterprises that have batch production requirements for thin sheet metal plates.

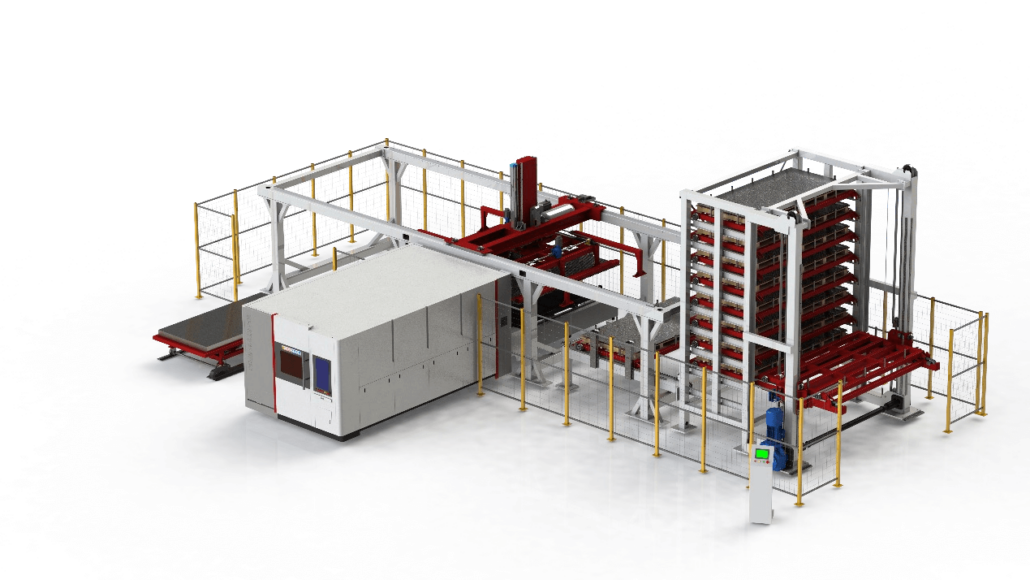

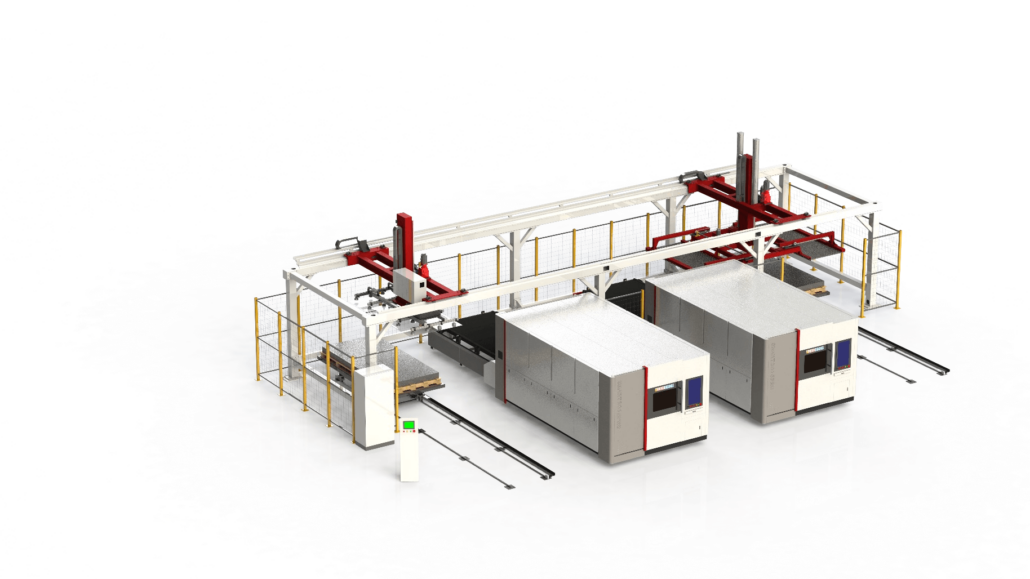

Smart HCS+HCL

Smart HCS+HCL automatic sheet metal loading and unloading and storage system

Sheet metal size: min1.2*1.2, max6*2m

Sheet metal thickness: 1~15mm (6020 10mm)

Maximum weight of a single sheet metal plate: 500kg (3015 15mm)

Features:1.Intelligent sheet metal storage system is directly connected to the laser cutting equipment seamlessly.2.Using unique dual working head design to achieve ultra-high-speed sheet metal loading and unloading, stable operation. And capable of expanding visual inspection and sorting of finished cutting pieces.3.Capable of expanding to multiple laser cutting equipments online production

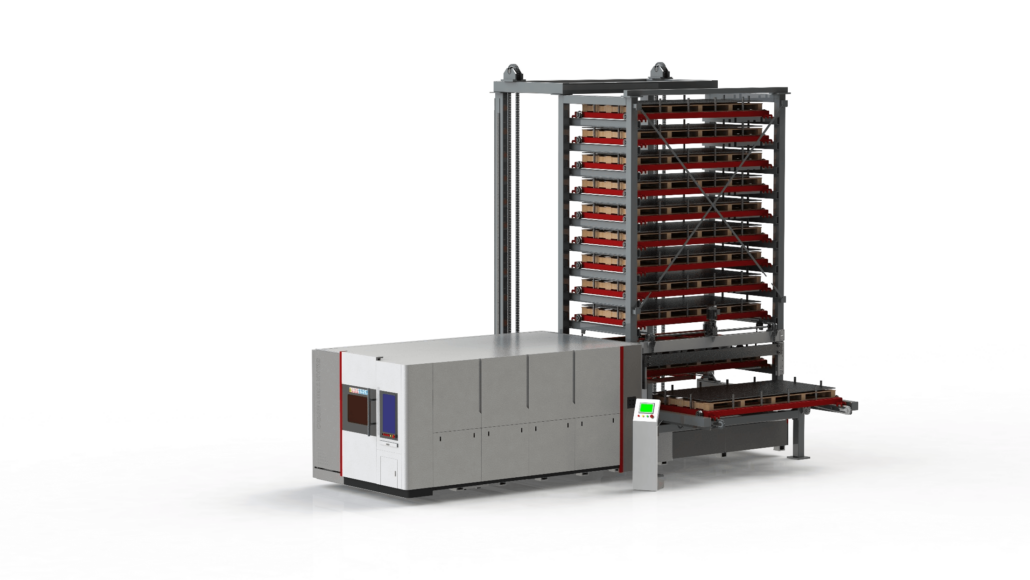

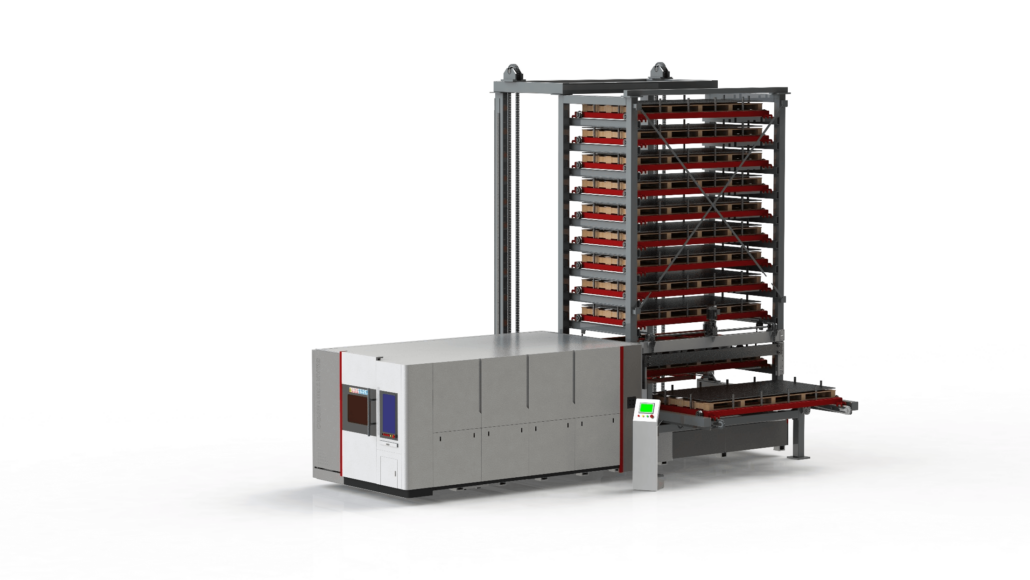

Smart HCJ

Smart HCJ compact sheet metal storage tower

Sheet metal size: min2*1m, max4*2m

Sheet thickness: 1~15mm (3015 format)

Maximum weight of a single sheet: 500kg (3015 15mm)

Features: 1.Intelligent sheet metal storage tower is directly connected to the laser cutting equipment, with compact structure, space-saving.

2.One-stop solution for heet metal storage, cutting, loading and unloading, finished product stacking.

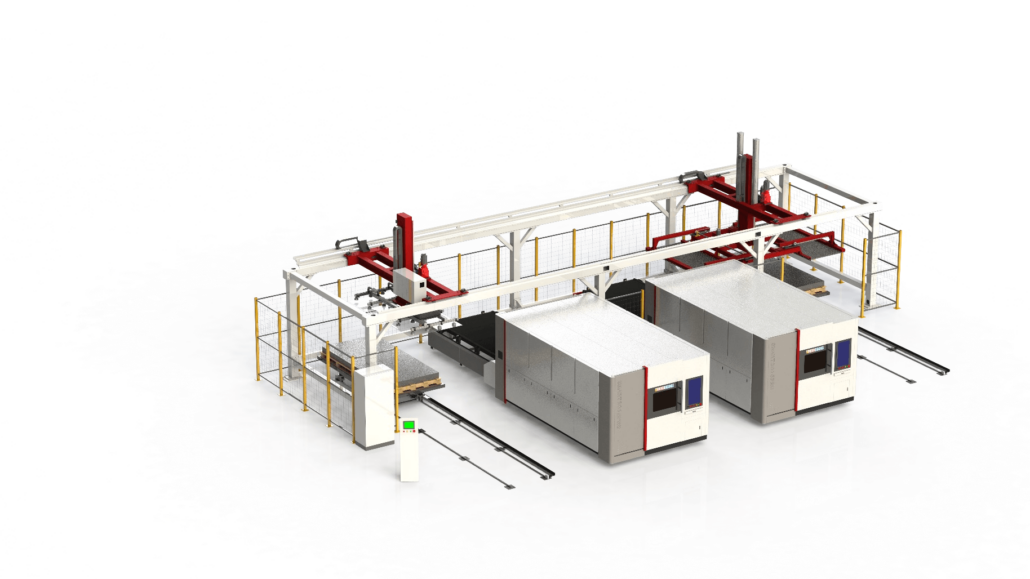

Smart HCL

Smart HCL automatic sheet metal loading and unloading

Sheet metal size: min0.5*1m, max6*2m

Sheet metal thickness: 1~15mm (3015)

Maximum weight of a single plate: 750kg (3015 15mm)

Features:Seamless connection with laser cutting equipment, compact structure, space saving, flexible, easy operation, with a variety of layout methods.