Laser tube cutting machine helps industrial development

In recent years, with the rapid growth of the economy and the rapid development of industrial manufacturing, there has been a high demand for raw materials. Heavy metal tubes are in high demand in large-scale industries, and the development of industry has also driven the use of heavy metal tubes. Laser tube cutting machines are one of the main equipment for metal tube processing. Next, this article will focus on the application fields of laser tube cutting machines and the advantages of laser tube cutting machines. Let’s take a look together in the article!

Application fields of laser tube cutting machines

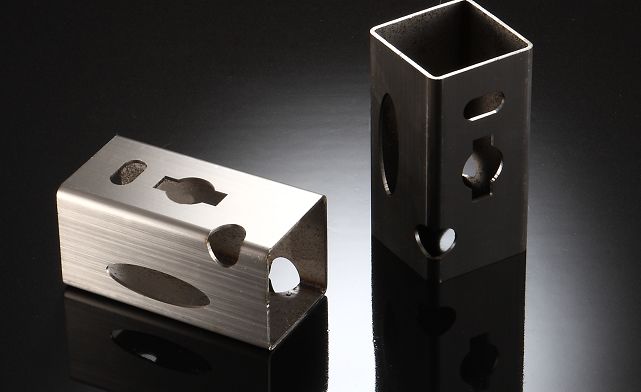

Laser tube cutting machine can cut various metal sheets and tubes, mainly suitable for fast cutting of materials such as stainless steel, carbon steel, manganese steel, copper sheet, aluminum sheet, galvanized sheet, various alloy sheets, rare metals, etc.

Widely involved in mechanical and electrical equipment, sheet metal processing, chassis and cabinets, stainless steel products, kitchen and bathroom, lighting fixtures, accessories, automotive parts, glasses, hardware tools, advertising signs, decoration and many other industries.

The advantages of choosing a laser tube cutting machine

1. High precision and efficiency in tube cutting

The truly unique feature of laser tube cutting machines is their cutting accuracy. They use chuck and push cutting methods, which have high centering and processing accuracy. Due to the improvement of modern

laser cutting machines, industrial manufacturing applications involving small diameter tubes have been greatly accelerated. The laser tube cutting machine can make corresponding adjustments based on these deformations to ensure the accuracy of tube cutting, which is not achievable by many traditional processes.

2. Strong flexibility in cutting tubes

By using tube cutting software, seamless recognition of tube shapes drawn by 3D software can be achieved, while supporting automatic generation of some commonly used tube workpieces. The laser tube cutting machine can cut any pre programmed shape on metal tubes, and the laser can complete perfect cutting in any direction. Through computer programming design, changes can be made flexibly and quickly. The high flexibility of laser tube cutting machines provides strong technical support for more and more personalized processing, thereby reducing the number of molds used.

Summary

The production and consumption of metal tubes are increasing day by day, and the demand for tube processing is increasing. The birth of laser tube cutting machines has injected new blood into tube processing. The use of laser tube cutting machines can seamlessly cut metal and other materials. After programming the machines, they can be widely used in customized cutting operations.