Projects

Application of Laser Cleaning Technology in the Electronic Industry

In the field of industrial applications, laser cleaning objects are divided into two parts: substrate and cleaning material. The substrate mainly includes surface pollution layers of various metals, semiconductor chips, ceramics, magnetic materials, plastics, and optical components. The cleaning material mainly includes a wide range of application requirements for industrial fields such as rust removal, paint removal, oil removal, film/oxide layer removal, and resin, adhesive, dust residue removal. The following is an introduction to the application of laser cleaning technology in the electronic industry.

Laser cleaning machines utilize a new efficient and pollution-free cleaning technology, which has significant advantages compared to traditional cleaning techniques. In industrial production, cleaning technology is often needed. This article summarizes the application of laser cleaning technology in electronic device cleaning. With years of laser research and development experience, the product technology is mature, and the product performance is safe and stable.

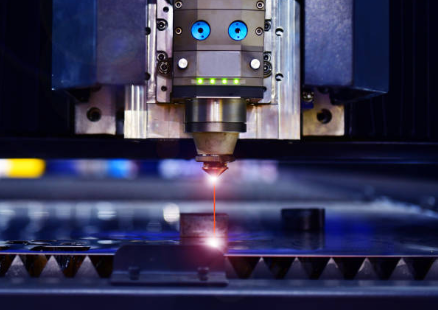

Laser cleaning technology refers to the process of using high-energy laser beams to irradiate the working surface, causing the surface dirt, rust spots, or coatings to evaporate or peel off instantaneously, effectively removing attachments or surface coatings on the cleaned object surface at high speed, thus achieving a clean process. It is a kind of non-contact processing, which can easily realize remote operation, and can be combined with robots or manipulators through optical fiber transmission to facilitate automatic operation; Able to clean areas that are not easily accessible by traditional methods; Low cost of decontamination; It can selectively clean the dirt on the surface of the material without damaging its internal composition and structure.

At present, laser cleaning technology includes three cleaning methods: dry laser cleaning technology, wet laser cleaning technology, and laser plasma shock wave technology. As one of the first batch of laser equipment manufacturers,HG tech has always focused on the research and development of laser technology and the development needs of customers, committed to providing every customer with comprehensive laser processing solutions.

- Dry laser cleaning refers to the direct irradiation of a pulse laser to clean the workpiece, causing the substrate or surface pollutants to absorb energy and increase the temperature, resulting in thermal expansion or substrate thermal vibration, thereby separating the two. This method can be roughly divided into two situations: one is the absorption of surface pollutants by laser expansion; Another method is for the substrate to absorb laser and generate thermal vibrations.

- Wet laser cleaning is a process in which a liquid film is pre coated on the surface of the workpiece to be washed before being irradiated by a pulsed laser. Under the action of the laser, the temperature of the liquid film rapidly increases and vaporizes. At the moment of vaporization, a shock wave is generated, which acts on the pollutant particles, causing them to detach from the substrate. This method requires that the substrate and liquid film cannot react, thus limiting the range of application materials.

- Laser plasma shock wave is a spherical plasma shock wave generated by breaking through an air medium during laser irradiation. The shock wave acts on the surface of the substrate to be washed and releases energy to remove pollutants; The laser does not act on the substrate, so it does not cause damage to the substrate. Laser plasma shock wave cleaning technology can now clean dozens of nanoparticle sized particle pollutants, and has no limit on laser wavelength.

The above is the application of laser cleaning technology in the electronic industry. Typical applications of laser cleaning technology include: mold cleaning, industrial rust removal, removal of old paint and film layers, pre welding and post welding treatment, ester removal of precision parts, decontamination and oxidation layer removal of electronic components, etc. Laser cleaning machines are also widely used in industries such as metallurgy, molds, automobiles, hardware tools, transportation, construction appliances, machinery, etc.

About HGSTAR: HGSTAR is is a sub-brand of HGTECH.HGTECH the pioneer and leader of laser industrial application in China, and the authoritative provider of global laser processing solutions. We have comprehensively arranged laser intelligent machine, measurement and automation production lines, and smart factory construction to provide overall solutions for intelligent manufacturing.