Projects

Manufacturing Solution for the Shipbuilding Industry (Part 2): Automatic Production Line

I.Intelligent Laser Cutting Automatic Production Line

Intelligent Laser Cutting Automatic Production Line includes several specialized lines, such as those for component cutting, deck cutting, and profile cutting. The workshop’s process layout is designed with a focus on optimizing product manufacturing logistics. Through modeling and simulation, the production line layout, manufacturing routes, logistics, and distribution are all carefully planned to ensure the most efficient configuration. This approach guarantees smooth, convenient, and orderly flow of workpieces throughout the production process.

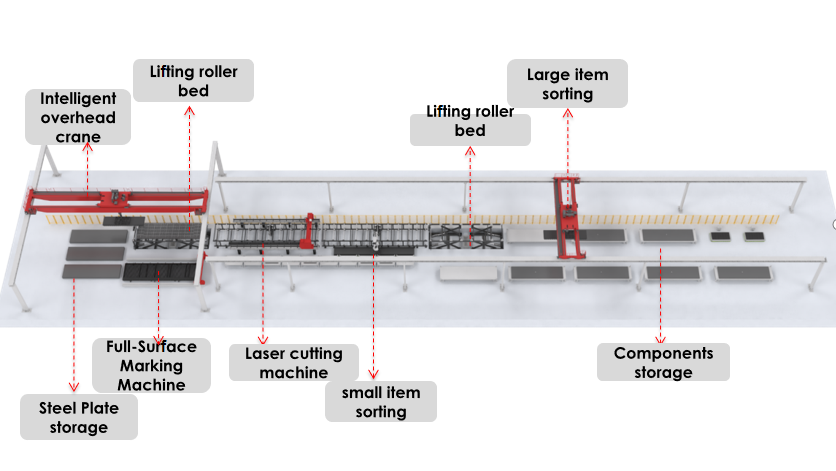

Component Cutting Line

Centralized blanking and ultra-flexible production for large steel plates of various thicknesses, enabling automated and unmanned flexible material preparation.

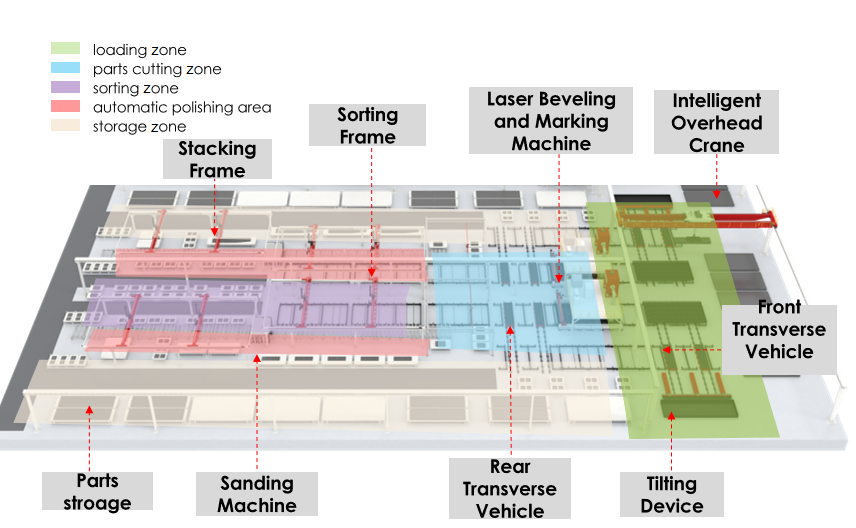

Deck Cutting Line

Automation of cutting, chamfering, and transferring large-sized parts such as decks.

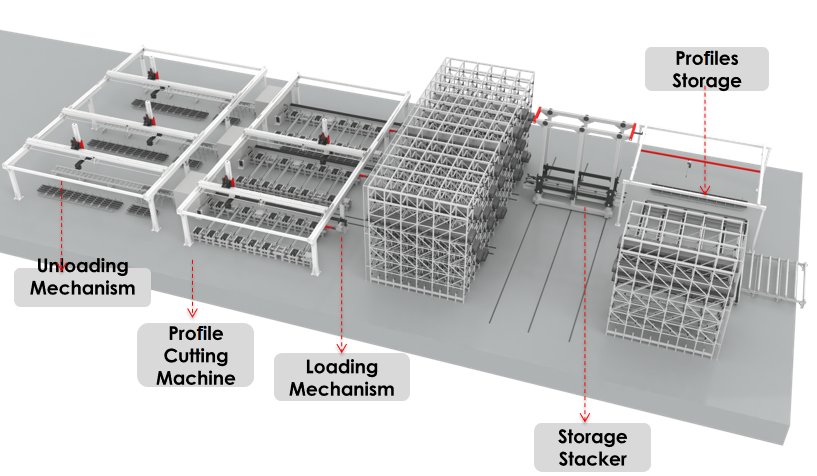

Profile Cutting Line

Full automation of the entire process for various profiles, such as bulb flats and angle steel including loading, conveying, length setting, cutting, unloading and transferring.

II. Intelligent Laser Welding Automatic Production Line

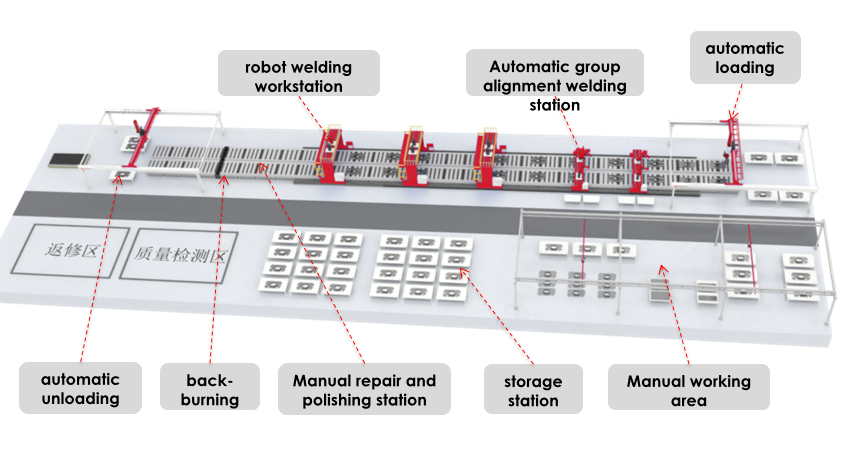

Intelligent welding production line is designed for flexible and intelligent welding of structural components of various sizes and specifications. The system is equipped with a Manufacturing Execution System (MES) and intelligent scheduling system, featuring automatic error-proofing capabilities. It enables full automation of welding, logistics, and material handling processes.

Thin Plate Welding Intelligent Production Line

In the construction of large, high-end ships, to reduce the overall weight and lower the center of gravity of the vessel, thinner steel plates with thicknesses ranging from 4mm to 12mm are commonly used as raw materials for the steel structures above the waterline. Traditional gas-shielded welding techniques often result in high heat input, significant welding deformation, and low welding efficiency. However, the application of laser hybrid welding technology can greatly improve welding efficiency, shorten the shipbuilding cycle, and reduce the consumption of welding wire, electricity, and gas. When combined with an automated production line, it further minimizes manual intervention and enhances the welding quality of the ship plates.

Thin Plate Flat Section Welding Intelligent Production Line utilizes high-power laser hybrid welding equipment to precisely control the assembly and splicing accuracy of steel plates. By applying visual sensing technology, it achieves seam tracking and weld path correction, integrating advanced laser hybrid welding technology to minimize deformation of thin plates during the welding process. Additionally, the line incorporates industrial IoT technology with an intelligent central control system, logistics systems, and other IoT and software technologies, enabling flexible and intelligent welding.

Small Sized Assembly Welding Intelligent Production Line

Shipbuilding process is akin to “building blocks,” where the hull is divided into different sections and units for modular construction, followed by assembly and integration to complete the main hull structure. As the most basic and fundamental structural components of the hull, the welding quality of small sized assemblies directly impacts the structural safety of the ship. Traditional welding methods heavily rely on manual labor and require highly experienced operators. The arc light and harmful gases generated during the welding process can severely affect the health of the welders and contribute to environmental pollution. The Small Sized Assembly Welding Intelligent Production Line minimizes heat-induced deformation of components during welding and significantly improves welding efficiency through automation, reducing reliance on manual operations and enhancing overall safety and environmental conditions.

Small Sized Assembly Welding Intelligent Production Line is equipped with manual assembly and spot welding stations, as well as automated welding stations. It utilizes adaptive logic programming technology to automatically identify welding structures without the need for programming or teaching. The system supports 3D model imports and possesses autonomous welding path planning capabilities, enabling flexible and intelligent welding production.

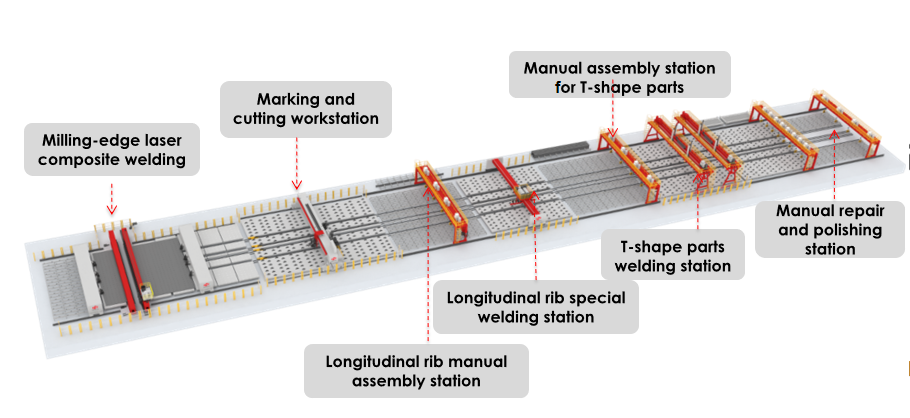

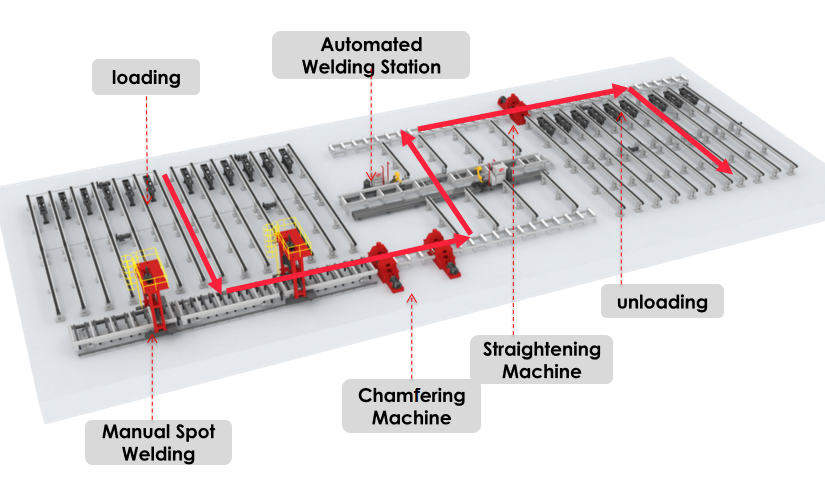

T-Profile Weldingn Itelligent Production Line

T-Profile Welding Intelligent Production Line is equipped with functionalities for T-profile panels and webs pre-assembly, profile assembly positioning and welding, panel chamfering, automatic transverse movement of T-profiles, automatic welding, and automatic correction of T-profiles. This line achieves flexible and intelligent production for T-profile welding processes.

In recent years, HGTECH has keenly understood the significant demand for transformation and upgrading within the shipbuilding industry. Leveraging our established and mature product lines, we have continuously developed new processes, products, and solutions tailored to the unique operational conditions of the maritime sector, actively aligning with the needs of intelligent shipbuilding. Additionally, in response to the green and smart manufacturing trends in high-end shipbuilding, HGTECH is focusing on the forefront of new energy vessels, accelerating the development of comprehensive intelligent manufacturing solutions for advanced green ships.