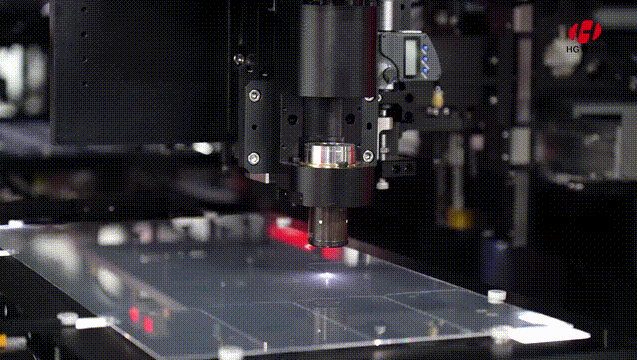

Introduction to Laser Cutting Technology Laser cutting is an advanced manufacturing process that uses a high-energy laser beam to cut materials with exceptional precision and speed. By focusing the beam on the surface of the workpiece, it generates intense heat—often reaching tens of thousands of degrees Celsius—rapidly melting, vaporizing, or ablating the material. With the…

Challenges in Steel Processing and the Limitations of Traditional Techniques In modern industrial manufacturing, steel is widely used across sectors such as construction, machinery, transportation, and energy due to its high strength, excellent processing performance, and broad application potential. However, the hardness and variety of steel also pose significant challenges to processing methods. Traditional…

On May 20, 2025, the highly anticipated BUTECH International Machinery Exhibition grandly opened in Busan, South Korea.HGLaser made a stunning appearance, showcasing cutting-edge laser intelligent manufacturing technologies for automotive, heavy machinery, and shipbuilding industries—demonstrating the robust strength of China’s laser industry to the global market! 01. Star Products Leading Laser Intelligent Manufacturing AUTOBOT3015 – 3D…

The door ring is a vital structural element in vehicle design, connecting the door to the body-in-white and forming the first line of defense during side impacts. Traditional manufacturing relies on welding multiple stamped steel parts, a process that introduces complexity, deformation, and inconsistency. Laser Tailor Welding offers a transformative solution by using high-energy…

Breaking Welding Bottlenecks In large-scale shipbuilding, final welding and assembly is regarded as the critical last step in ensuring structural integrity and manufacturing precision. However, conventional welding processes such as Submerged Arc Welding (SAW) and Gas Metal Arc Welding (GMAW) are increasingly falling short when it comes to large-block assembly, high-strength material joining, and…

Hydrogen Development Accelerates as Manufacturing Bottlenecks Demand Breakthroughs As the global energy structure shifts toward a greener and low-carbon model, hydrogen—known as the “ultimate energy”—is entering a crucial phase of commercial deployment. Across the entire hydrogen value chain, from hydrogen production systems to fuel cell stacks and storage solutions, there is an increasing demand…

In the fast-paced manufacturing world, industries are always looking for ways to enhance efficiency, precision, and product quality. When it comes to cutting glass, one technology stands out: CO₂ laser glass cutting. This cutting-edge method is changing the way we work with glass across construction, automotive, and consumer electronics, offering precise cuts with minimal waste…

On April 22, HGTECH’s core subsidiary HGLaser and Swiss company Synova officially announced the establishment of a joint venture in Beijing. The two parties held in-depth discussions on implementing the joint venture’s strategic roadmap and deeply integrating Laser MicroJet® applications, jointly exploring prospects for future cooperation. The founding ceremony was attended by Mr. Deng Jiake,…

China International Machine Tool Show · CIMT On April 21, the China International Machine Tool Show opened grandly in Beijing. HGLaser showcased two groundbreaking intelligent devices centered around high-end manufacturing, demonstrating its strong capabilities in independent research and development. The solutions presented include “Laser + Intelligent Manufacturing” for industries such as automotive manufacturing, sheet metal…

With the rapid growth of Electric Vehicles (EVs) and energy storage systems, the production of Battery Packs has become a critical component of battery manufacturing. Manufacturers face the core challenge of ensuring high quality while improving production efficiency and controlling costs. Laser technology, known for its high precision, non-contact processing, and efficiency, is playing an…