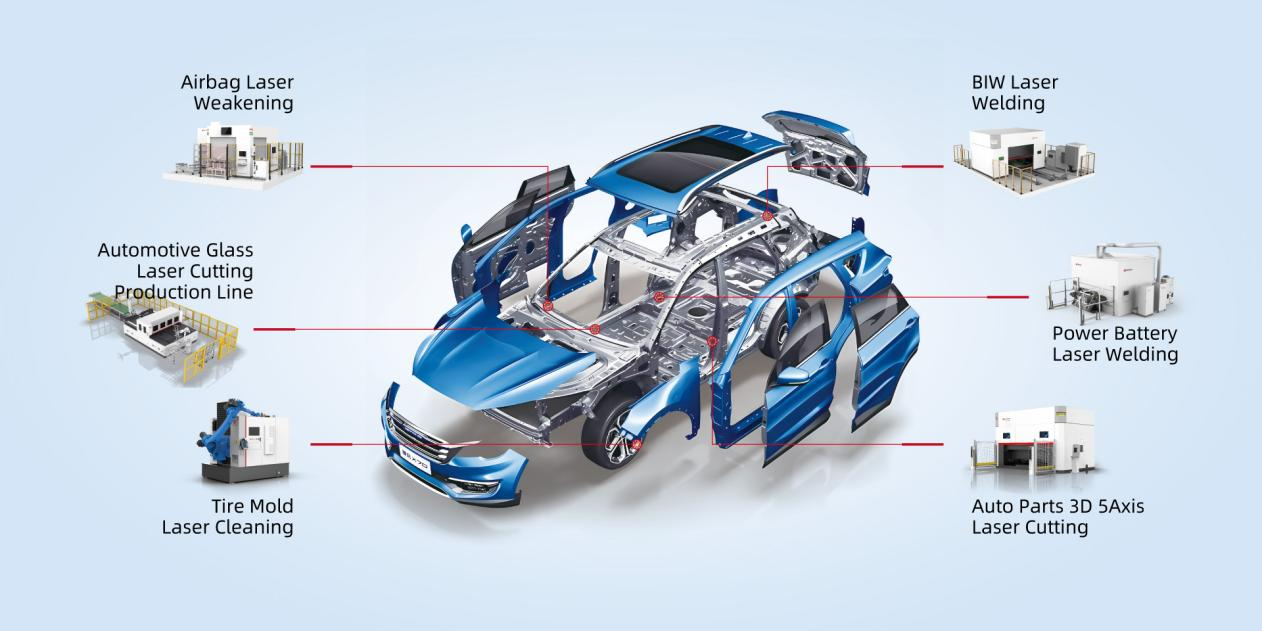

As electric vehicles and autonomous driving expand, automotive manufacturing is adopting intelligent upgrades to enhance efficiency, quality, flexibility, and cost-effectiveness.

Building on its expertise, HGTECH provides advanced solutions for key components like battery, door rings, A/B pillars, tire molds, and airbags, while continuously addressing specialized needs. Our solutions now cover essential areas like car seat welding, AC pipeline laser welding, and bumper cutting and welding—fueling new momentum in the automotive industry.

Car Seat Laser Welding: Precision + Flexibility

In the automotive living space, seats are undoubtedly the part with the largest contact area and the longest usage time. Its quality defines the experience of every journey. However, traditional manufacturing methods use spot welding and arc welding processes, which present issues such as: insufficient precision, thermal deformation and reduced material strength.

While Laser welding technology, with its high precision, small heat-affected zone, and high adaptability, has become a new trend in the automotive seat manufacturing industry.

HGTECH Car Seats Flexible Welding Intelligent Equipment

- Versatile Applications: Welds seat components (rails, recliners, brackets) across materials like metal and plastic.

- High Precision: Controlled welding paths minimize deformation, ensuring accuracy and consistency.

- Flexible Automation: Supports mass production with fully automated, defect-reducing processes.

- Enhanced Durability: Strengthens seat structure, improving overall durability.

AC Pipeline Laser Welding:Efficiency + Lightweighting

The pipeline system is the lifeblood of automotive air conditioning system, whose production process is complex with strict sealing requirements. Traditional flame welding methods often lead to deformation and low efficiency. With the accelerating demand for lightweight vehicles,the use of aluminum in automotive manufacturing continues to rise.

To address the challenges of aluminum alloy AC pipelines, HGTECH has developed advanced Aluminum Alloy AC Pipelines Laser Welding Machine, effectively solving common issues such as hot cracking, porosity, and deformation.

HGTECH Aluminum Alloy AC Pipelines Laser Welding Machine

- High Success Rate: Success rate exceeds 99%.

- Efficient Production: Three-axis control, dual-station worktable, 8-second cycle.

- Flexible Setup: Contour-based fixtures with quick changeover.

- High Precision: ±0.03mm accuracy for tubes φ8-φ25mm, 80-1200mm length.

- Superior Quality: Smooth, defect-free welds with no cracks, porosity, or depressions.

Bumpers Laser Cutting and Welding:Integration + Automation

The vehicle’s front and rear bumpers not only serve a decorative purpose but also absorb and cushion external impacts, providing added protection for the body and occupants. Car bumpers require precision machining for various radar, license plate, and camera holes, along with welding of multiple brackets on the back.

Traditional methods, such as ultrasonic and mechanical punching, face challenges: high production and maintenance costs, limited flexibility, inconsistent punching quality. HGTECH Bumper Integrated Cutting and Welding System solves all these problems and enables both laser cutting and ultrasonic welding on a single platform.

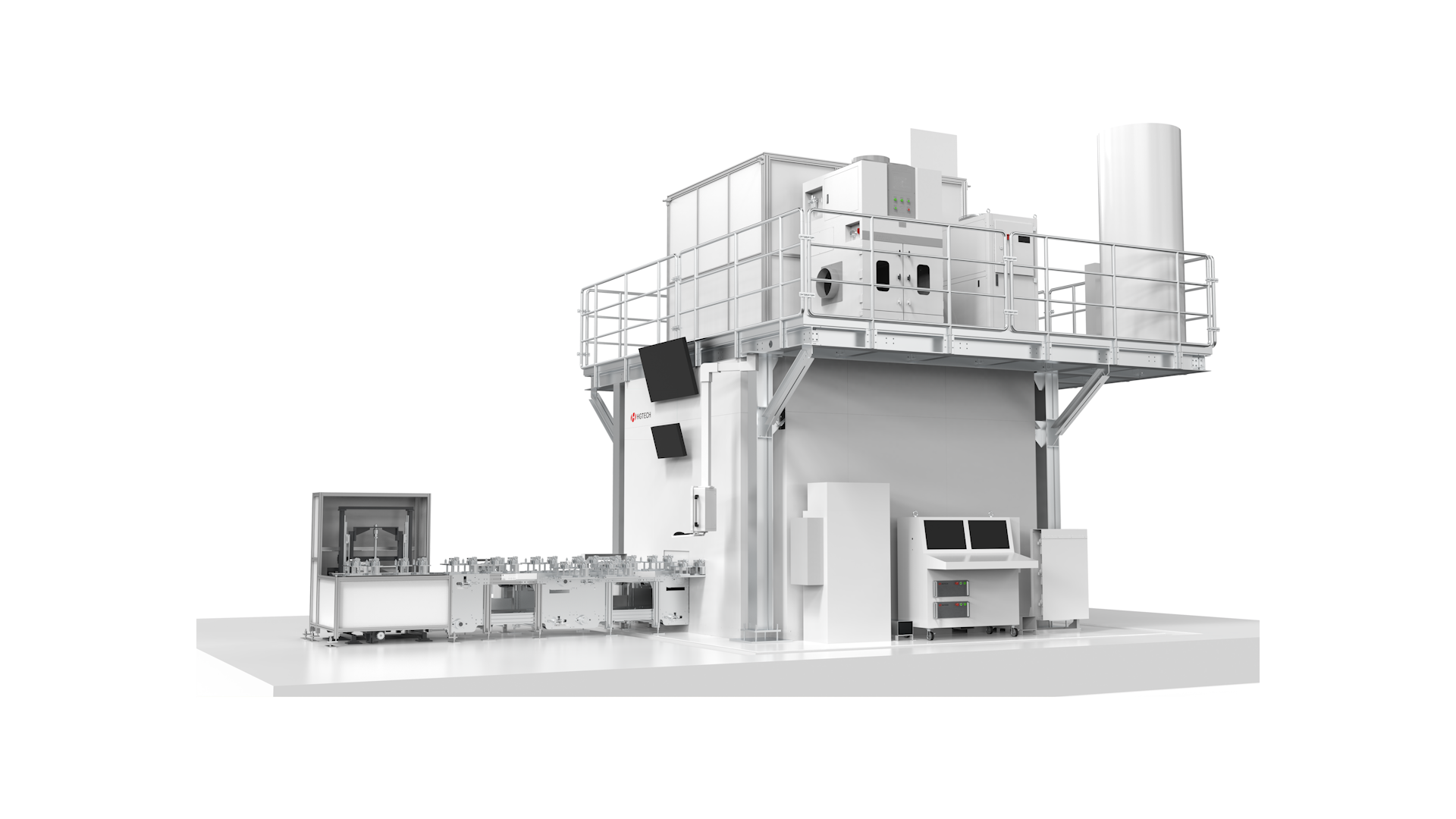

HGTECH Bumper Integrated Cutting and Welding System

- Three Modules: H-Series Dual-Station Punch-Welding, Flexible Robotic Laser Drilling, Rotating Worktable Laser Drilling Machines.

- High-Speed Dual-Robot System: Synchronized cutting and welding for efficient production.

- Consumable-Free Cutting:Micro-hole cutting without tools or punches.

- Automated Flexibility:Rapid die changes, extensive pattern storage, and mixed-model compatibility.

HGTECH is leading the intelligent transformation of automotive manufacturing, delivering precision, efficiency, and flexibility to meet the demands of electric and autonomous vehicles. With advanced laser technology, HGTECH empowers the industry’s shift toward a smarter, greener future.