Projects

Laser Automatic Production Line Of Efficient Loading And Unloading

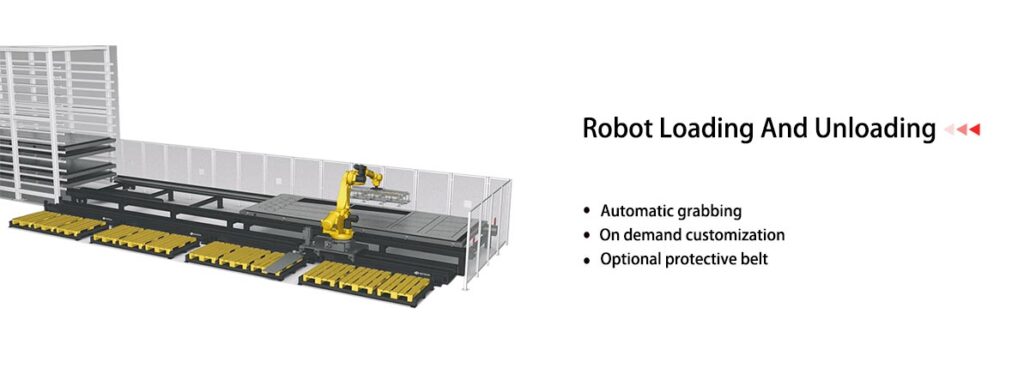

The important role of automatic loading and unloading

The automatic loading and unloading of materials on laser automated production lines plays an important role in industrial manufacturing. It significantly improves production efficiency, reduces labor costs, and maximizes production efficiency. Meanwhile, by ensuring the accurate placement of workpieces, laser automation technology ensures the accuracy and consistency of marking, cutting, and other operations, thereby improving product quality. In addition, this technology reduces human operational errors, enhances work stability and reliability, and brings great convenience and benefits to industrial manufacturing.

Five advantages of automatic loading and unloading

Highly integrated: The automatic loading and unloading system integrates various functional modules through modular design, making the entire system more compact and efficient. This design not only reduces the footprint of the equipment, but also facilitates its installation, debugging, and maintenance.

Flexibility and Scalability: The modular design of automation makes the automatic loading and unloading system highly flexible and scalable. Enterprises can choose different modules for combination based on actual needs to meet different production needs. Meanwhile, with the expansion of production scale, the system can also be easily expanded to meet higher production capacity requirements.

Standardization and Interchangeability: Each module is designed and manufactured according to a unified standard, and each module undergoes strict testing and verification. Therefore, modular design can ensure the reliability and stability of the entire system. Ensure good interchangeability between modules. This means that when repairing or replacing modules, enterprises can quickly find suitable replacement modules, reducing maintenance costs and time costs.

Intelligent control: Modular design also incorporates intelligent control elements. Through advanced sensors and control systems, various modules can achieve collaborative work and automatically complete loading and unloading tasks. At the same time, the system can also monitor the operating status in real time, perform fault diagnosis and early warning, and improve the reliability and stability of the equipment.

Easy to maintain and upgrade: The modular design makes maintenance and upgrading of the automatic loading and unloading system easier. Enterprises can perform targeted maintenance and upgrades for a particular module without the need for extensive system modifications. This greatly reduces maintenance costs and extends the service life of the equipment.

Summary

The modular design characteristics of the automatic loading and unloading system of HGTECH give it significant advantages in improving efficiency, reducing costs, and enhancing flexibility, providing strong support for the production automation and intelligent upgrading of enterprises.