Projects

Laser Automation Application In Construction Machinery Industry

Opportunities for Automation

In the wave of rapid development of the national economy, the construction machinery industry, with its fundamental and strategic importance, has provided solid support for the rise of infrastructure and manufacturing industries. With the deepening promotion of infrastructure construction and manufacturing industry transformation and upgrading, laser automation has ushered in unprecedented development opportunities in the construction machinery industry.

Opportunities for automated production lines

The traditional production mode is no longer able to meet the growing production demand, especially in the laser processing of metal raw materials such as medium thick steel plates and heavy pipes, the limitations of traditional manual operations are gradually becoming prominent. Therefore, the emergence of laser automated production lines undoubtedly injects new vitality into the innovative development of the engineering machinery industry.

The laser cutting process, as a key link in the manufacturing process of engineering machinery, has the characteristics of large processing batches and high standardization. The traditional manual cutting method is not only inefficient, but also difficult to ensure accuracy, making it difficult to meet the high standards and precision requirements of modern engineering machinery manufacturing. The introduction of laser automated production lines has broken this bottleneck. By connecting the links of raw material management, automatic loading and unloading, laser cutting, intelligent sorting, and automatic tray matching, the automation of the material cutting process has been achieved, greatly improving production efficiency and product quality.

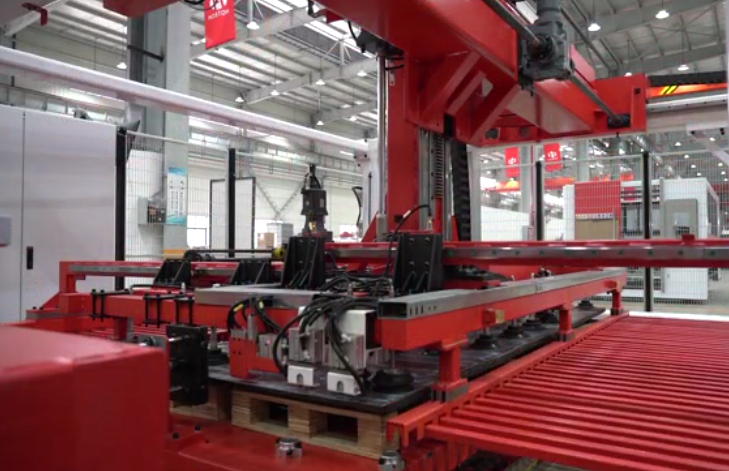

The automated laser cutting production line, with its three-dimensional material warehouse assembly characteristics, is particularly suitable for large-scale, multi specification automated flexible laser cutting processing. This production line integrates intelligent three-dimensional material storage, automatic transmission system, automatic sorting system, whole board online coding system, and central control system, achieving intelligent operation of multiple links. Through functions such as automatic loading and unloading, automatic polishing, and automatic sorting, not only labor costs are saved, but production efficiency is also improved, providing strong support for increasing production and increment for enterprises.

It is worth mentioning that HGTECH’s LCK laser automated production line has been widely used in the construction machinery industry. This production line not only improves efficiency and reduces labor costs, but also reduces the labor intensity of workers, achieving unmanned operation at night and meeting the demand for 24-hour uninterrupted, high-efficiency, high-precision continuous production.

Summary

For large engineering manufacturing enterprises such as thick and heavy plates, LCK automated production lines can fully meet their production needs and provide excellent solutions for the sheet metal processing industry.