Projects

Laser Cleaning: Four Laser Cleaning Methods And Application Fields

As a recognized manufacturing power in the world, China has made great strides and achievements on the road of industrialization, but it has also led to serious environmental degradation and industrial pollution. In recent years, China’s environmental protection regulations have become increasingly strict, leading to some enterprises being shut down for rectification. A one size fits all environmental storm has some impact on the economy, and changing traditional pollution production models is the key. With the advancement of technology, people are gradually exploring various technologies that are beneficial for environmental protection, and laser cleaning technology is one of them. Laser cleaning technology is a newly applied surface cleaning technology for workpieces in the past decade. It is gradually replacing traditional cleaning processes in many fields due to its advantages and irreplaceable nature.

Traditional cleaning methods include mechanical cleaning, chemical cleaning, and ultrasonic cleaning. Mechanical cleaning uses mechanical means such as scraping, wiping, brushing, and sandblasting to remove surface dirt; Wet chemical cleaning method uses organic cleaning agents to remove surface attachments by spraying, showering, soaking, or high-frequency vibration; The ultrasonic cleaning method involves placing the processed parts into a cleaning agent and utilizing the vibration effect generated by ultrasonic waves to remove dirt. At present, these three cleaning methods still dominate the cleaning market in China, but they all generate pollutants to varying degrees, which greatly limits their application in environmental protection and high-precision requirements.

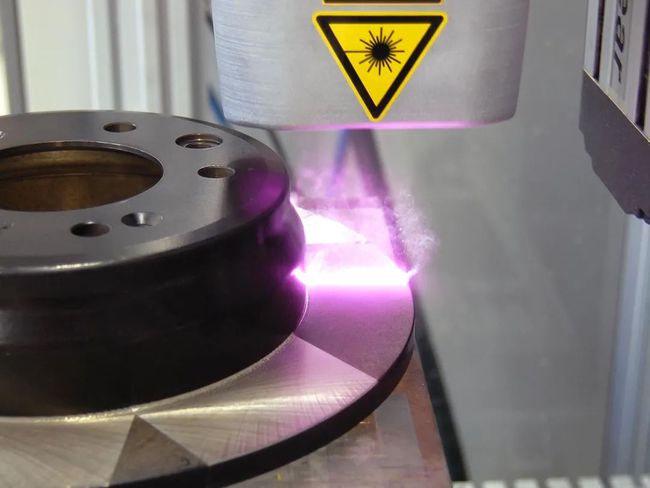

Laser cleaning technology refers to the use of high-energy and high-frequency laser beams to irradiate the surface of workpieces, causing instantaneous evaporation or peeling of dirt, rust spots, or coatings on the surface, effectively removing attachments or surface coatings on the cleaned object surface at high speed, thus achieving a clean laser process. The characteristics of lasers are high directionality, monochromaticity, high coherence, and high brightness. By focusing the lens and Q-switching, the energy can be concentrated in a small space and time range. From a methodological perspective, there are four laser cleaning methods:

- Laser dry cleaning method, which uses pulse laser direct radiation for cleaning;

- Laser+liquid film method, which first deposits a layer of liquid film on the surface of the substrate, and then uses laser radiation to decontaminate; When a laser is irradiated on a liquid film, the film is rapidly heated, producing explosive vaporization. The explosive shock wave causes the dirt on the surface of the substrate to loosen. And fly away from the surface of the processed object with the shock wave to achieve the purpose of decontamination.

- The method of laser+inert gas is to use inert gas to blow towards the surface of the substrate while laser radiation is applied. When dirt is peeled off from the surface, it will be immediately blown off the surface by the gas to avoid surface contamination and oxidation again;

- After using laser to loosen the dirt, clean it with non corrosive chemical methods. At present, due to the development of China’s high-end manufacturing industry and the continuous improvement of environmental protection requirements, traditional cleaning technologies (chemical method, mechanical polishing method) are far from meeting the needs of industrial production in China. The backwardness of cleaning technology limits the normal production and operation of some important industries in China. Therefore, laser cleaning technology, as a representative of green and efficient manufacturing, has a broad market scale in the rapid development of China’s high-end manufacturing industry.

Compared with traditional cleaning methods, laser cleaning is a “green” cleaning method that has unparalleled advantages: no need to use any chemical agents or cleaning fluids, and the cleaned waste is basically solid powder, small in size, easy to store, adsorbable and recyclable, non photochemical reaction, no noise and environmental pollution, while not damaging the health of operators, and easy to achieve automation control, Realize remote cleaning.

The widespread application of laser cleaning in various fields:

Mold cleaning. Laser can achieve contactless cleaning of molds, which is very safe for the surface of the mold and ensures its accuracy. It can also clean submicron scale dirt particles that cannot be removed by traditional cleaning methods, achieving true pollution-free, efficient, and high-quality cleaning. Accurate ester removal cleaning in the precision instrument industry.

The precision machinery industry often requires the removal of esters and mineral oils used for lubrication and corrosion resistance on parts, usually using chemical methods, and chemical cleaning often still has residues. Laser ester removal can completely remove esters and mineral oils without damaging the surface of the parts. Laser induced explosive vaporization of a thin layer of oxide on the surface of the part, forming a shock wave, resulting in the removal of dirt rather than mechanical interaction.

Rail cleaning. At present, all pre welding cleaning of steel rails is carried out using grinding wheels and abrasive belts. The substrate is severely damaged, residual stress is severe, and a large amount of grinding wheel consumables are consumed every year, resulting in high costs and serious dust pollution to the environment. Laser cleaning can provide high-quality and efficient green cleaning technology for the production of high-speed railway track laying in China, solve the above problems, eliminate welding defects such as seamless rail holes and gray spots, and improve the stability and safety of high-speed railway operation in China.

Aviation sector. The surface of the aircraft needs to be repainted after a certain period of time, but the original old paint needs to be completely removed before painting. Chemical soaking/wiping is the main paint removal method in the aviation industry, which causes a large amount of chemical auxiliary waste and cannot achieve local maintenance paint removal. This process is labor-intensive and harmful to health. Laser cleaning can achieve high-quality removal of paint on aircraft skin surfaces and is easy to achieve automated production. At present, this technology has been applied to the maintenance of some high-end models abroad.

Ship field. At present, the main method of ship pre production cleaning is sandblasting, which causes serious dust pollution to the surrounding environment and has gradually been banned, resulting in reduced production or even shutdown of ship production enterprises. Laser cleaning technology will provide a green and pollution-free cleaning solution for ship surface anti-corrosion spraying.

Military industry. Laser cleaning technology is widely used in weapon maintenance and upkeep. By using a laser cleaning system, rust and pollutants can be efficiently and quickly removed, and the cleaning area can be selected to achieve automation. By using laser cleaning, not only is the cleanliness higher than that of chemical cleaning processes, but there is almost no damage to the surface of the object.