The furniture industry is currently evolving in four directions: refinement, scalability, branding, and technological innovation.

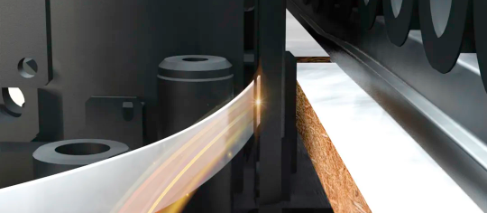

Laser edge banding technology, as the latest seamless edge banding technology, typically uses an edge banding tape with a functional layer of only 0.1 to 0.2 mm in thickness. It compensates for the shortcomings of traditional EVA/PUR hot-melt adhesive edge banding in terms of efficiency and environmental impact, ensuring high edge quality and production efficiency, while improving the aesthetic appearance of furniture.

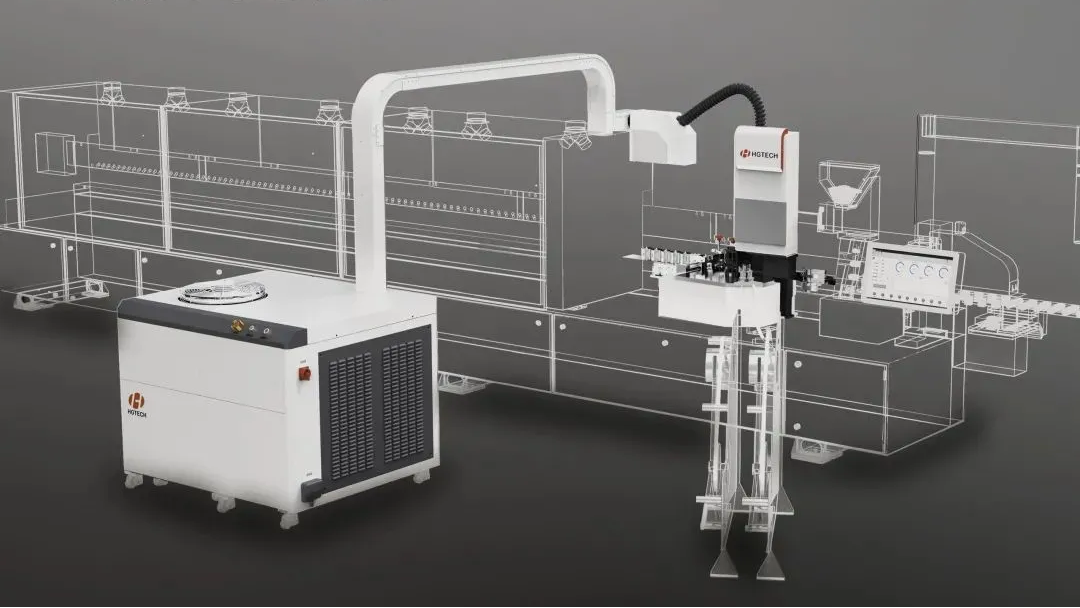

HGTECH LASER HEAD Laser Edge Banding System meets the development needs of the furniture industry in terms of refinement, scalability, branding, and technological innovation.

High-Speed

With its proprietary flying laser control system, the system achieves a processing speed of 25 m/min, perfectly matching the edge banding speed of top-tier international brand machines.

Durable

Equipped with cutting-edge 5th generation laser technology, the system boasts an optical-to-electrical conversion efficiency exceeding 30% and a design life of up to 100,000 hours, ensuring maintenance-free operation.

Worry-Free

There are no special environmental requirements, eliminating the need for a temperature- and humidity-controlled factory environment, thus reducing complex maintenance and upkeep costs.

Intelligent

With a one-click laser mode switch, the system ensures reliable, safe, and user-friendly operation. Thanks to a comprehensive process parameter library, simply input product dimensions and board type to achieve seamless laser edge banding, saving time through intelligent automation.

Safe

Compliant with Level 1 protection standards, it incorporates high-precision laser energy control technology to precisely regulate processing temperature without the use of adhesives. Additionally, the system is equipped with an explosion-proof dust extraction system, ensuring a safe and environmentally friendly production process.

To fully meet market demands and drive the “intelligent manufacturing” upgrade in the furniture industry, HGTECH has developed two models of the Laser Edge Banding System, the 3030 and 3030P. These systems feature a modular design with high compatibility. With just a few simple installation steps, they can upgrade traditional edge banding machines or be added to new machines without changing the original structure of the machine.

HGTECH, addressing the actual needs of the furniture industry and the pain points of industry manufacturing upgrades, has innovated domestic alternatives, offering better prices, improved services, and more easily upgradeable solutions.

Starting with the “Laser Head” Laser Edge Banding System, which embodies the concept of “Seamless Edge Banding, Laser-Powered Intelligent Manufacturing,” HGTECH will further align with the furniture industry’s trends of refinement, scalability, branding, and technological innovation. Through advanced laser and automation technologies, HGTECH aims to provide comprehensive “Laser + Intelligent Manufacturing” solutions, realizing the vision of upgrading the furniture manufacturing industry towards technology and intelligence.