Projects

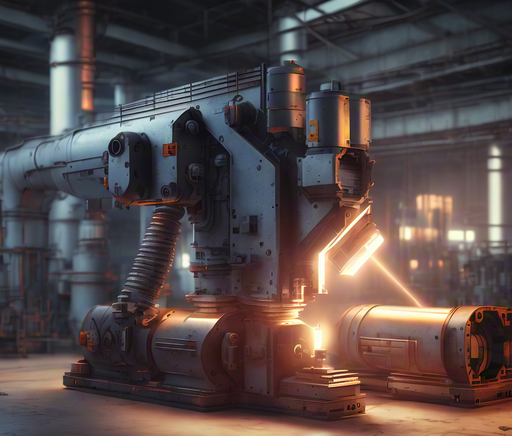

Laser Is A New Engine Upgrade Of Manufacturing Automation

Technological innovation in laser automation

With the rapid development of global manufacturing, technological innovation has become a key factor in promoting the competitiveness of enterprises. In this context, compact laser automation systems, with their advantages of high precision, high efficiency, and compact design, are gradually becoming a new engine for upgrading the manufacturing industry.

A New Standard for High Precision Manufacturing

In the manufacturing industry, accuracy is crucial. The laser automation system can achieve micro level cutting, welding, and marking processes through the high-precision characteristics of laser technology, ensuring that each manufacturing process meets the ultimate precision requirements. This not only improves the appearance quality of the product, but also ensures the performance stability and reliability of the product, winning the trust of the market for the enterprise.

A leap in production efficiency

Traditional manufacturing processes often have low efficiency and cannot meet the market’s demand for rapid response and high output. The laser cutting automation system, with its efficient working performance, greatly shortens the production cycle. Whether it is the production of components in automobile manufacturing or the manufacturing of circuit boards in electronic devices, this system can achieve fast and stable processing, significantly improving the production efficiency of enterprises and helping them respond quickly to market demand.

Diversity in material handling

The automatic laser cutting production line has a wide range of material processing capabilities. Whether it is metal, non-metal, or composite materials, this system can perform efficient and accurate processing. This eliminates the need for frequent equipment replacement or process adjustments during the manufacturing process, greatly improving production flexibility and efficiency.

The combination of automation and intelligence

With the rise of intelligent manufacturing, automation and intelligence have become important development directions in the manufacturing industry. The compact laser automation system integrates advanced control systems and algorithms to achieve automated operations and intelligent management. This not only reduces the difficulty and error of manual operations, but also improves the automation level of production lines, bringing higher production efficiency and lower operating costs to enterprises.

The Assistance of Environmental Protection and Sustainable Development

Traditional manufacturing processes often come with environmental pollution and energy consumption. As an efficient and environmentally friendly manufacturing technology, laser cutting machines with loading and unloading systems can reduce energy consumption and waste emissions while ensuring product quality and production efficiency. This provides strong technical support for enterprises to achieve environmental protection and sustainable development.

Summary

In summary, the application of laser automation systems in the manufacturing industry is gradually becoming a new trend. It has brought unprecedented changes and upgrades to the manufacturing industry with its powerful advantages.