Projects

What’s the Role of Chucks In Tube Laser Cutting Machine?

Subdivided Products Under Laser Cutter—Three-chuck Laser Pipe Cutting Machine

As an efficient method of operation in metal profile processing, laser cutting has been highly praised by all walks of life after years of market precipitation. In order to cope with market demand, laser cutting machines are now divided into plate laser cutting machines and pipe laser cutting machines. In comparison, laser pipe cutting machines have a wider development prospect and application space. As a product of industry segmentation, the three-chuck laser pipe cutting machine has many advantages worthy of our analysis. A laser pipe cutting machine can replace multiple processing processes such as mechanical drilling, milling, sawing, stamping or cleaning burrs. One piece of equipment can complete metal pipe cutting, drilling, beveling and other processes. It is currently widely used in Sheet metal processing, kitchenware, lighting, automobiles, hardware, fitness equipment and other industries.

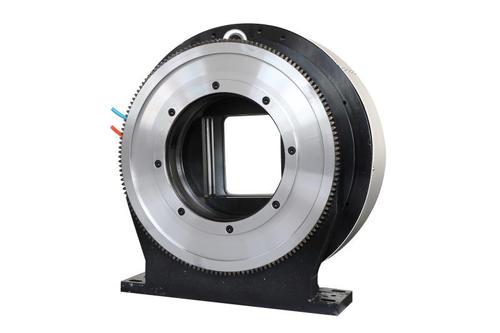

Structure of Chucks

The three-chuck laser pipe cutting machine has two pneumatic chucks at the front and rear, and an electric chuck in the middle; the three chucks can clamp and cut at the same time, with high cutting accuracy. It has the advantages of simple operation, convenience and low maintenance cost. The chuck has a self-adjusting center function, which can ensure the horizontal state of the pipe during the cutting process, enabling rapid centering and clamping; the system has a free and automatic edge search function to reduce the occurrence of collisions of the cutting head.

Functions And Advantages of Three-chuck Laser Pipe Cutter

The three-card structure combined with the double clamping function of the middle chuck can assist in correcting the self-deformation of small pipes and improve cutting accuracy. Segmented feeding and cutting improve cutting accuracy and high-speed and fully automatic cutting can meet the needs of round pipes, square pipes, and rectangular pipes. Cutting of other special-shaped pipes can achieve zero tailing cutting and improve material utilization.

Compared with manual chucks, chucks of tube laser cutting equipment can be clamped or released in an instant by simply pressing the handheld box or button to inhale air. The clamping force is stable and reliable. The clamping force of the chuck can be adjusted according to the weight of the pipe fittings, and the claws can also be customized according to the customer’s different types of pipe fittings, saving time and effort, and greatly improving the customer’s laser cutting efficiency.

The pneumatic chuck can still firmly hold the product for laser cutting even when the air source is cut off, overcoming users’ concerns about safety and stability. At the same time, the laser pneumatic chuck adopts a fully enclosed structure, which has a strict anti-fouling effect. The heat treatment process and cutting process used for the internal structural parts ensure the service life of the chuck. Applying laser cutting chucks to reduce production processes and equipment, automated work sites can reduce labor costs and compressive strength, improve corporate image, and enhance the competitiveness of new products.