Projects

The Smart Manufacturing of Shipbuilding Industry

The Smart Manufacturing of Shipbuilding Industry

China has a long history in shipbuilding industry. However, due to various historical factors, China’s shipbuilding industry has developed slowly over the past few decades, lagging far behind those in developed countries. Establishing a modern mode has become an inevitable requirement to promote China’s shipbuilding industry. In the current international shipbuilding landscape, where shipbuilding capacity tends to saturate and the prices of production materials soar, it is imperative to utilize resources such as materials, funds, information, talent, equipment, and land effectively. It means we should comprehensively promote the full digitization of shipbuilding industry, production monitoring, and workshop management. This will enable us to realize the development plan of becoming a shipbuilding power successfully.

Bottlenecks in the Shipbuilding Industry

1.Low Automation Level

Although some shipbuilding enterprises have introduced a certain number of shipyard laser cutting machine, the majority of welding, assembly and processing tasks still rely on manual or mechanized labor.

2.Lack of Production and Quality Monitoring in Workshop

The utilization rate of production equipment in shipbuilding workshops is low, while the energy consumption is high. Moreover, there’s a lack of effective quality monitoring, resulting in severe data gaps regarding precision.

3.Non-transparent Workshop Management

Most manufacturing enterprises have a coarse approach to workshop execution management, lacking the capability to collect, transmit, and control status data on key production elements. This prevents the implementation of process management for production scheduling based on limited capacities. As a result, there is a significant gap in quality, efficiency, and cost control compared with advanced foreign enterprises.

The Development Goal of Smart Manufacturing in Shipbuilding Industry

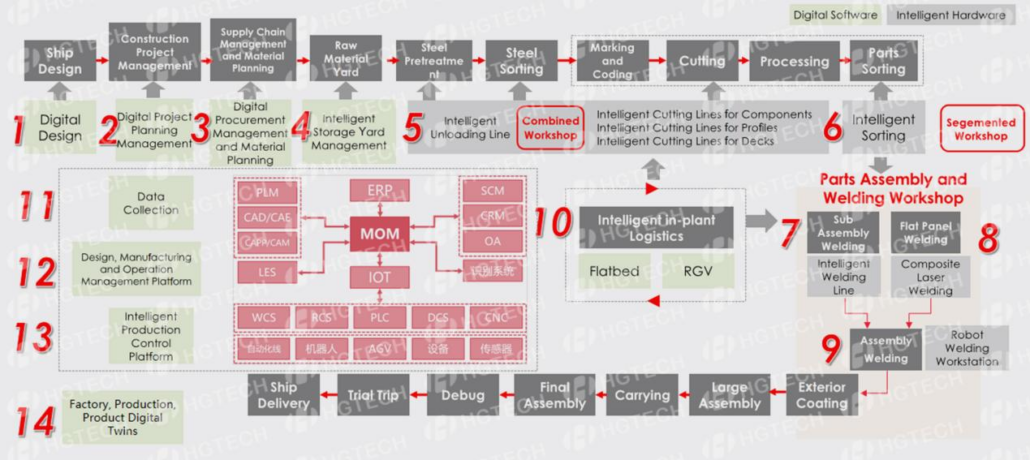

1. Manufacturing Driven by Digital Signal

It is necessary to establish a workshop control network and introduce smart manufacturing equipment to cover key processes in shipbuilding industry. Replace traditional analog signal with digital signal in information transmission and process coordination. Utilize digital signal on processing, welding, measurement, inspection, and assembly of components and semifinished products.

2. Production and Quality Data Collection

Utilize workshop Internet of Things (IoT) integration technology to collect and control real-time status data of personnel, equipment, materials, and environment through sensors, intelligent instruments, and automatic control equipment, achieving real-time monitoring of workshop status. Sensors, digital measurement, and inspection equipment should be used to conduct real-time online monitoring on shipbuilding quality and accuracy and optimization decisions should be made in the process.

3.Transparent Scheduling and Control:

The shipbuilding workshop should collect real-time status data of production factors, construct workshop operation management models, optimize and flexibly configure processes, materials, technologies, and tooling. Besides it need to implement lean production and agile manufacturing guided by customer demands, helping companies reduce costs and improve efficiency.

Meanwhile, HGTECH is empowering the high-quality development of the shipbuilding industry through the “laser + intelligent manufacturing” approach to build a digital factory.

Key Technologies for Digital Factories in the Shipbuilding Industry

HGTECH, with planning as its core and algorithms as its driving force, offers integrated and turnkey services by leveraging software-defined hardware.

With planning as its core, driven by algorithms, and hardware defined by software, HGTECH provides integrated and packaging services. We utilize intelligent equipment including high-speed marking and coding machines, laser cutting equipment, laser composite welding workstations, and laser automated cleaning equipment etc.

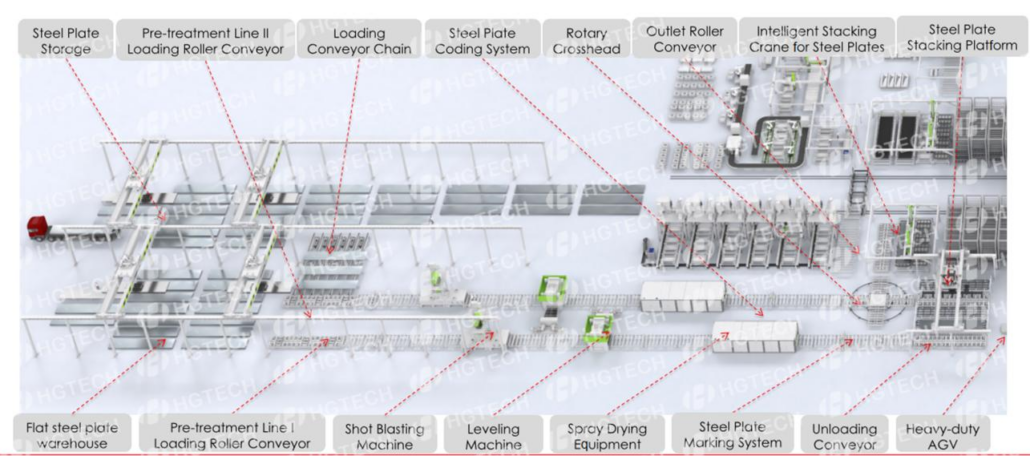

Raw Materials Pre-processing and Steel Plate Sorting Conveyor Line

Today, HGTECH has gradually applied advanced manufacturing processes, robotics, and new-generation information technology to the field of shipbuilding. Looking ahead, we aim to extensively integrate advanced AI technologies such as robotics, digital twins to achieve high-quality production, ultimately realizing the vision of an intelligent unmanned factory.