Projects

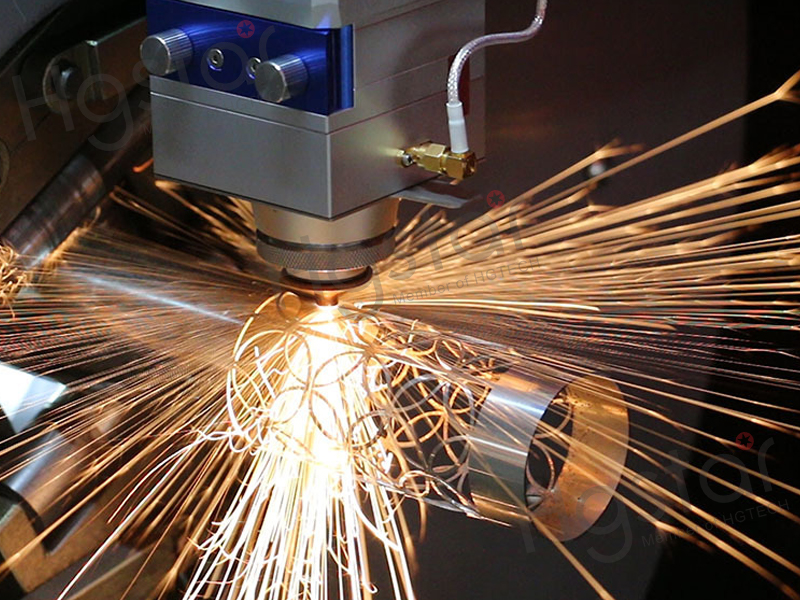

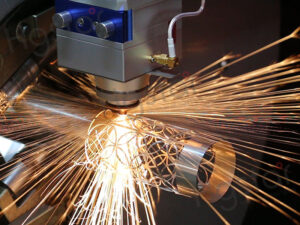

Tips For Cutting Aluminum With A Fiber Laser Machine

The manufacturing industry in China is highly developed. Fiber Laser Machines have gradually solved the efficiency problem of metal processing in recent years. The most common metals are stainless steel, carbon steel, and aluminum plates. Until now, both stainless steel and carbon steel have been easily cut.

Cutting aluminum, a highly reflective material, has always been a challenge for fiber laser machines. The high-reflective material has a low laser absorption rate, whereas aluminum is a market staple, prompting us to consider how to cut aluminum with a fiber laser machine.

1. If the final appearance of the aluminum material is unimportant, the aluminum material can be painted black, which effectively reduces the reflectivity of the aluminum material to the laser, allowing the aluminum material to be cut more easily.

2. If funds are available, a larger laser can be replaced. The light reflectivity of common aluminum materials is approximately 70%. A 3000W power cutter can cut 8 mm of aluminum material, and a 6000W power cutter can cut 16 mm of aluminum material. Choose a fiber laser cutting machine with a higher power rating based on the thickness to be cut, as this will allow you to cut aluminum more effectively.

3. The cutting process can be tweaked to produce a better cut of aluminum. Because aluminum is not resistant to high temperatures, burrs will form if the cutting residence time is not correct. Aluminum can be cut by adjusting the cutting focus, speed, output power, air pressure, and other parameters.

4. Select the appropriate auxiliary gas. Due to the special color of aluminum, nitrogen can prevent oxidation and retain the properties of the material itself, ensuring the uniform color of the cut product. Nitrogen is a better alternative.

In general, fiber laser cutting machines are not difficult to use when cutting aluminum. Many manufacturers on the market have developed cutting heads with anti-reflective materials, which can effectively reduce the lens damage caused by reflection.

Aluminum can be easily cut as long as the processing technology is patiently adjusted and the cutting speed is monitored. Here are some tips for cutting aluminum with a fiber laser machine that I hope will be useful to everyone.