Projects

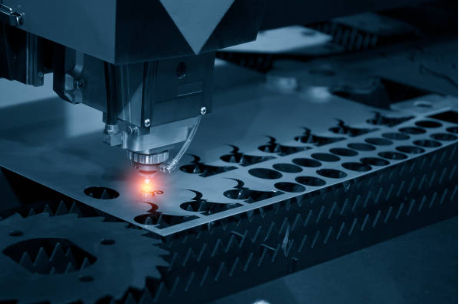

Use and Differentiation of Laser Metal Cutting Machines

Metal laser cutting machine is a type of machine equipment that uses metal to create and laser technology to cut metal. Nowadays, many metal processing manufacturers choose to use laser cutting machines to cut metal.

The advantages of metal laser cutting

Metal laser cutting is an important production process in the industrial construction industry. At present, raw materials such as acetylene and propane are used in the cutting process to improve production efficiency and save energy. The so-called metal cutting machine, also known as a metal laser cutting machine, is the energy released when a laser beam is irradiated on the surface of a metal workpiece to melt and evaporate the metal workpiece for cutting or carving purposes. Accurate and fast cutting, not limited to cutting mode limitations, automatic layout saving materials, smooth cutting, low processing costs, etc.

The new generation of advanced metal laser cutting system has good optical mode and accuracy, and the mechanical follower cutting head directly contacts the plate to move, always maintaining the laser focus. The constant cutting speed and quality of the entire working surface are uniform; Dual track positioning, ball screw drive, fast speed, high precision, smooth motion, good dynamic performance, and long service life; The machine has an over travel anti-collision limit switch and polyurethane anti-collision bar after the limit is closed in the vertical and horizontal movement directions, ensuring the safe operation of the machine to the maximum extent possible; The automatic programming system directly generates a processing program for graphic files, simulates the graphic processing path with a computer, automatically discharges the sleeve, and improves processing efficiency and material utilization.

The Use and Differentiation of Metal Laser Cutting

As a new type of tool, metal laser cutting machines are increasingly being used in various industries. So how to use metal laser cutting? How to distinguish metal laser cutting?

Firstly, the energy of the laser is concentrated in a high-density beam of light. The beam is transmitted to the working surface, generating enough heat to melt the material. The high-pressure gas coaxial with the beam directly removes the molten metal, thereby achieving the purpose of cutting. This indicates that the cutting process of metal laser cutting machines is fundamentally different from that of machine tools.

It uses the laser beam emitted from the laser generator to focus into high-power density laser beam irradiation conditions through an external circuit system. The laser heat is absorbed by the workpiece material, and the workpiece temperature rises sharply. After reaching the boiling point, the material begins to evaporate and form. When the beam of light moves relative to the workpiece, the hole ultimately forms a slit in the material. The process parameters (cutting speed, laser power, gas pressure, etc.) and the trajectory of the slit are controlled by a CNC system, and the slag at the slit is blown away by a certain pressure of auxiliary gas.

In the process of metal laser cutting, auxiliary gases suitable for cutting materials are also added. When cutting steel, oxygen is used as an auxiliary gas to produce exothermic chemical reactions with the molten metal to oxidize the material, while also helping to blow away the slag in the grid. For metal components with high machining accuracy, nitrogen can be used as an auxiliary gas. Most organic and inorganic compound materials can be cut by metal laser.

With the development of technology, the popularity of fiber laser metal cutting machines has reached a peak in recent years. A series of industries have achieved profits through the use of this machine, such as medical equipment, display industry, transportation engineering, hardware manufacturing, and furniture industry.

About HGSTAR: HGSTAR is is a sub-brand of HGTECH.HGTECH the pioneer and leader of laser industrial application in China, and the authoritative provider of global laser processing solutions. We have comprehensively arranged laser intelligent machine, measurement and automation production lines, and smart factory construction to provide overall solutions for intelligent manufacturing.