Projects

Advantages of UV PCB Laser Cutting Machine

PCB and FPC are important components and circuit connection carriers in the 3C industry.

With the continuous development of intelligence in the electronics industry, PCBs and flexible circuit boards (FPCs) are becoming smaller and thinner, accommodating more and more electronic components, and requiring higher machining precision. At the same time, the application of lasers on PCBs and flexible circuit boards is becoming increasingly widespread.

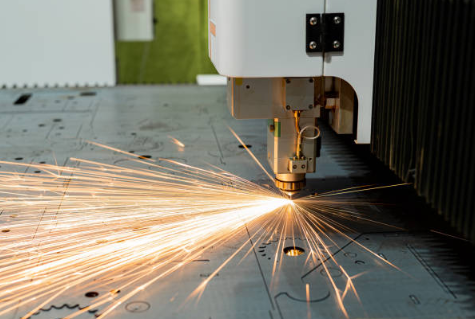

Advantages of UV PCB Laser Cutting Machine in Processing PCB Circuit Boards

1) Compared with CO2 laser, it is more suitable for a wider range of materials. Except for aluminum substrates, almost all material products can be processed, such as FR4, fiberglass board, paper substrate, copper clad plate, etc. In addition, the wavelengths of ultraviolet and green light are shorter, the pulse width is smaller, the thermal effect is small, and there will be no burning phenomenon.

2) Non contact machining can be applied to any shape without being affected, thus in the PCB circuit board industry, compared to traditional machining methods, it does not require any adjustments and can effectively improve response speed for any curve machining.

3) Good processing effect, short laser wavelength, low thermal impact, smooth cutting edges, no burrs, and no dust generated during the processing. It will not cause any stress on the PCB circuit board and will not deform the board.

4) High cutting accuracy, camera positioning, cutting gap less than 50 microns, high cutting position accuracy. Especially suitable for certain specific PCB sub board industries with high processing requirements.

5) The operation process is simple, and the software is automatically controlled. It can be connected to the automatic loading and unloading mechanism, saving labor costs.

With the arrival of the global 5G era, the materials and manufacturing processes of mobile phones will undergo changes to adapt to new 5G technologies, and a new round of business opportunities will bring huge economic benefits to laser equipment suppliers. The new market demand will be released and benefit all aspects of the industry chain. From the research and development trend of 5G commercial equipment and products, the PCB and flexible circuit board industry will become one of the biggest beneficiaries. PCB and flexible circuit board can be said to be blood transfusion pipelines for electronic products. Flexible circuit boards have the advantages of high wiring density, lightweight, flexible, and three-dimensional assembly, which are in line with market development trends and are in increasing demand. With the rapid development of the industry, the processing technology of flexible circuit boards is also constantly innovating.

In the electronics industry, most manufacturing processes are inseparable from the application of laser processing. The production efficiency and precision processing characteristics of advanced laser processing technology determine the importance of its position in electronic manufacturing. Laser marking, laser welding, laser cutting, laser drilling, laser etching, LDS laser direct forming, and other widely used in electronic manufacturing. The large-scale application of laser processing technology will bring huge economic benefits to laser equipment suppliers.

About HGSTAR: HGSTAR is is a sub-brand of HGTECH.HGTECH the pioneer and leader of laser industrial application in China, and the authoritative provider of global laser processing solutions. We have comprehensively arranged laser intelligent machine, measurement and automation production lines, and smart factory construction to provide overall solutions for intelligent manufacturing.