Projects

Advantages of Laser Cleaning for Electronic Components

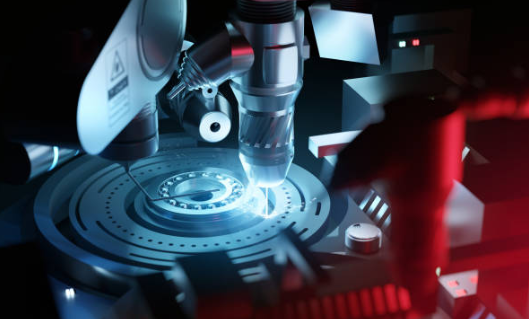

In 1969, Beadair et al. first proposed the concept of laser cleaning. Laser cleaning technology has the advantages of good cleaning effect, wide application range, high precision, non-contact and reachability. It is in sharp contrast with cleaning methods of detergent, ultrasonic and mechanical methods. It is expected to partially or completely replace traditional cleaning methods and become the most promising green cleaning technology in the 21st century.

In the 1980s, the rapid development of the semiconductor industry put forward higher requirements for the cleaning technology of contaminated particles on the surface of silicon wafer masks. The key point is to overcome the great adsorption force between the contaminated particles and the substrate. Traditional chemical cleaning, mechanical cleaning, and ultrasonic cleaning methods cannot meet the needs, while laser cleaning can solve such pollution problems, and related research and applications have been rapidly developed.

The small pollutants on electronic circuit boards can reduce electronic efficiency and cause damage to electronic circuit boards. With the development of technology, semiconductor and microelectronic devices are getting smaller and the particles that need to be cleaned are also getting smaller, making cleaning difficult. Traditional water washing and ultrasonic cleaning have their own shortcomings. Laser cleaning brings new hope and becomes the best cleaning method.

Polyimide film is an important material in electronic components. It is a dielectric material with internal link structure of multilayer packaging film for high-speed and high-density electronic components. However, it often covers some particulate pollutants, including titanium particles, chromium particles, tungsten particles, nickel particles, etc., which need to be cleaned to ensure that the polyimide film works normally. The laser machine company once conducted an experiment to clean the polyaniline film. Using excimer laser, select a laser with a wavelength of 235 nm, a pulse of 20 ns, and a laser energy density of 80 mj/cm2. Using automated robot operation, the cleaning efficiency is extremely high. After cleaning, it was found that the cleaning effect was excellent.

The spectrometer detected that the pollutant removal rate was more than 95%, which has reached the required standard, and the cleaning efficiency is high, Why not 100% decontamination? Why is there still 5% left? Can’t it be removed? “” Indeed, there is still 5% that has not been removed, but this does not mean it cannot be removed. The main reason is in the dry time and efficiency. In a complete decontamination time, 95% can be removed within 50% of the time, and the remaining 5% can be removed within 50% of the time. In practical operations, cleaning efficiency and cost are more important. “This indicates that there is still a certain gap between theory and practice, In practical applications, there is always a delicate balance between efficiency, effectiveness, and cost. Generally speaking, ordinary electronic components can remove 95% of pollutants, which is already an excellent cleaning effect.

There are many applications of lasers in the cleaning of electronic components, such as the cleaning of electronic circuit boards, silicon wafers, integrated circuits, software circuits, and optoelectronic devices. With the development of technology, these materials have improved integration, resulting in more and more pins and smaller holes.

Traditional cleaning methods are difficult to work with. Laser cleaning is highly accurate, easy to perform automated operations, and parameters can be adjusted, The advantages of high cleaning efficiency effectively remove dust, grease, oxides, and other particles from the surface of electronic components, effectively improving the durability of electronic components. Laser cleaning provides an effective and reliable technology for devices in the microelectronics industry that are small in size and difficult to clean with small particles. At the same time, laser cleaning does not cause wear and corrosion to the substrate material, meets environmental requirements, and can operate in narrow spaces, which is incomparable to any other cleaning process.

Laser cleaning meets environmental requirements and sustainable development needs. With the decreasing cost of laser cleaning, laser cleaning of electronic components has been accepted by more enterprises. Before 2016, the cost of laser cleaning electronic components was 20 times that of traditional water and chemical cleaning. With the development of laser cleaning technology and significant price reductions in laser cleaning equipment in the past eight years, the cleaning cost is now close to traditional costs.

About HGSTAR: HGSTAR is is a sub-brand of HGTECH.HGTECH the pioneer and leader of laser industrial application in China, and the authoritative provider of global laser processing solutions. We have comprehensively arranged laser intelligent machine, measurement and automation production lines, and smart factory construction to provide overall solutions for intelligent manufacturing.