Projects

AI in Laser Processing! HGTECH Releases AI Platform

Smart manufacturing is the trend of the times, and the fusion of laser technology with smart manufacturing is becoming increasingly mature. Under the new technological revolution sparked by generative AI, we actively explore how advanced technologies led by AI will promote new industrialization and develop new productive forces.

AI is becoming more deeply integrated and aligned with industry scenarios. It plays a role in major aspects of manufacturing such as production control, R&D Design, and business management. The product forms and application boundaries continue to expand, enriching and specifying the content of laser + smart manufacturing.

Production Control

Research and Development (R&D) Design

Business Management

In the era of innovation-driven comprehensive competition, HGTECH actively explores how AI empowers the field of Laser + Smart Manufacturing. Through research and development, product innovation, and market practices, we aim to promote high-quality development.

| Research and Development Practices |

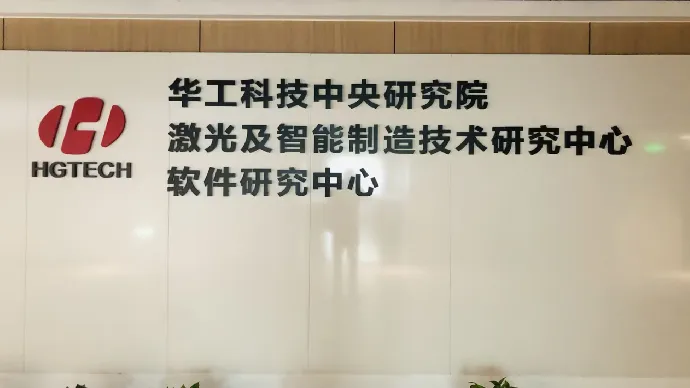

HGTECH establishes a Central Research Institute to strategize and deploy forward-looking innovative achievements. It clarifies the R&D positioning of each subsidiary, emphasizes industry-academia-research collaboration in innovation, and ensures the continuous extension of the innovation chain.

HGTECH Central Research Institute

Establishing AI Research Lab

Dedicated to enhancing AI capabilities complementary to laser smart manufacturing, connecting intelligent teaching, intelligent operation and maintenance, intelligent parameter optimization, and other AI applications throughout the entire process with intelligent interaction systems.

Currently developed:

AI application development platform

Laser digital human-machine interaction system

Vision sorting system

Industrial AI predictive analytics system

Factory digital twin

……

| Product Application |

Intelligent Equipment

China’s first All-weather Intelligent Laser Weeding Robot

AI vision recognition technology

Based on deep learning image classification, target detection technology, and distributed edge computing technology, it achieves intelligent identification of small and dense weed clusters under different lighting and weather conditions, greatly improving weed recognition accuracy and processing speed.

Digital Human-Machine Interaction System

Integrating conversational interaction technology, creating an intelligent interaction system supporting voice and text input, capable of facilitating equipment debugging tutorials, intelligent after-sales customer service, and other interactive applications.

Predictive Maintenance

Using machine learning, deep learning, and other algorithms to automatically predict potential equipment failures, optimize maintenance schedules, improve equipment utilization rates, and reduce maintenance costs.

Intelligent Fault Diagnosis

Using artificial intelligence algorithms to diagnose equipment faults, improving diagnostic accuracy, and automatically providing repair recommendations to enhance maintenance efficiency.

Intelligent Parameter Guidance and Optimization

Providing precise parameter guidance for laser processes based on physical and data models; employing deep learning optimization algorithms to automatically adjust key parameters such as laser power, scanning speed, and focal length to achieve optimal processing quality and efficiency.

HGTECH Self-developed “Abrain” Deep Learning Algorithm

- Efficiently learns and understands defect features

- Strong defect recognition capability

- Accurate defect classification capability

- Fast defect recognition speed

Automatic Production Line

POCT Reagent Filling Production Line in the Medical Industry

Status Monitoring and Intelligent Fault Diagnosis

Digitally modeling the health status of the production line, enhancing the self-awareness capability of the production line, achieving intelligent fault diagnosis, trend analysis, real-time alarm notifications, and other applications.

Hydrogen Energy Alkaline Electrolyzer Cell

Electrode and Grid Automation Line

Self-developed “Ransac+” Vision Algorithm

Using deep learning models, self-developed algorithms to recognize and track weld seam.

Quality Inspection and Automatic Analysis

AI quality inspection using advanced image recognition technology automatically identifies product defects; deep analysis based on data models identifies the root causes of defects.

Using machine learning to analyze production data, identifying bottleneck processes and providing optimization solutions to enhance overall efficiency and flexibility of the production line.

Smart Factory

One-stop Cloud Platform for Visualization in the Bridge Industry

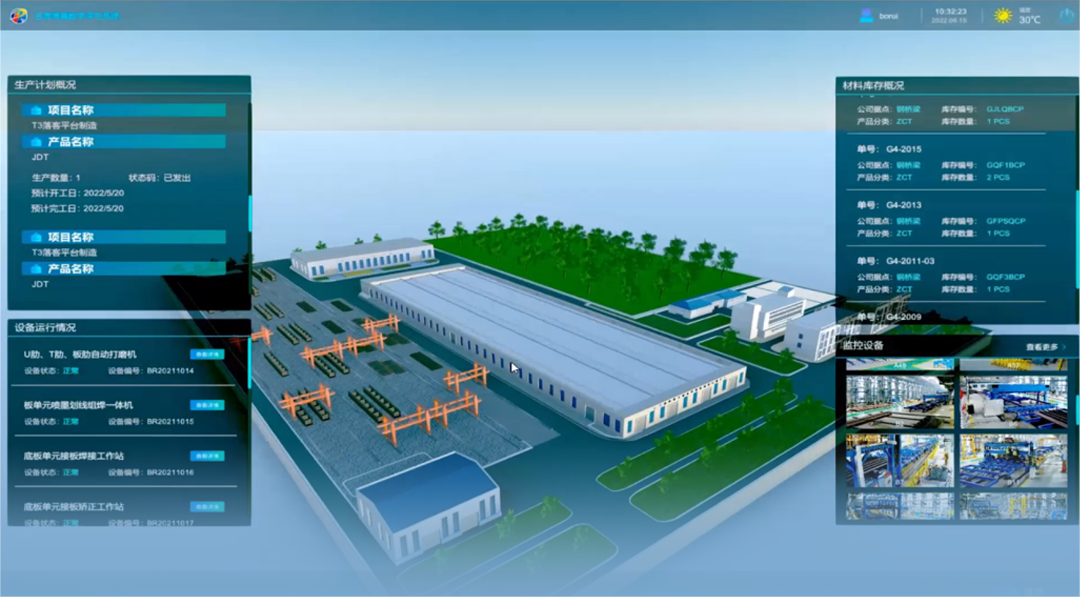

Digital Twin Factory for Steel Bridges

Intelligent Upgrade System for Digital Twin Factory

By modeling a three-dimensional digital model of the steel bridge factory, combining real-time IoT data collection with factory production process data, equipment status data, equipment energy consumption data, and equipment abnormal alarm information, it achieves real-time monitoring of twin models from factory, workshop, production line to equipment.

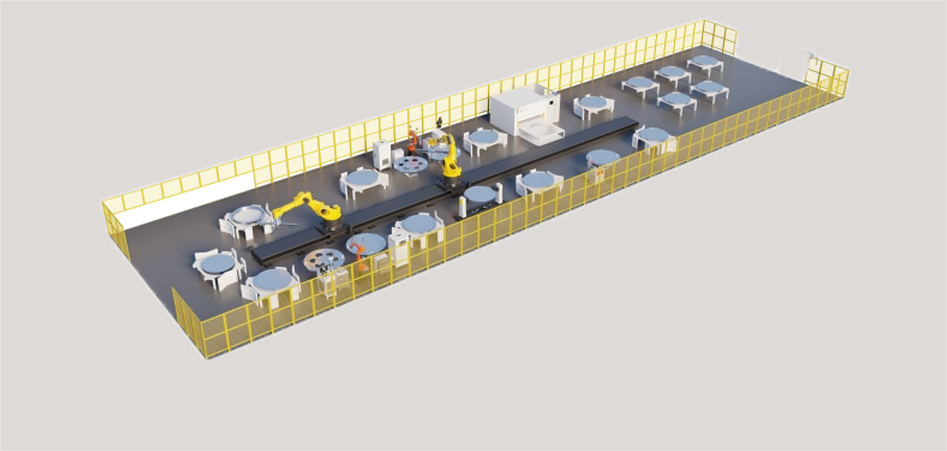

The first 5G smart factory in the pipe fittings industry in China

Automated smart factory for PVC pipe fittings

Intelligent Decision-Making

Utilizing a comprehensive data platform and employing AI algorithms for deep analysis and exploration of data to provide scientific and rational decision-making suggestions for the factory, achieving refined management.

Intelligent Scheduling

Based on production plans and inventory status, intelligently scheduling materials and production plans to improve efficiency.

HGTECH continues to foster new productive forces through innovation ecosystem cultivation, talent team construction, and the establishment of innovative platforms. Together with upstream and downstream industry chains and the industry-university-research innovation chain, it is actively promoting the full-chain digital transformation and intelligent upgrade.