Projects

Analysis of Laser Cutting Technology for Seven Major Metal Materials

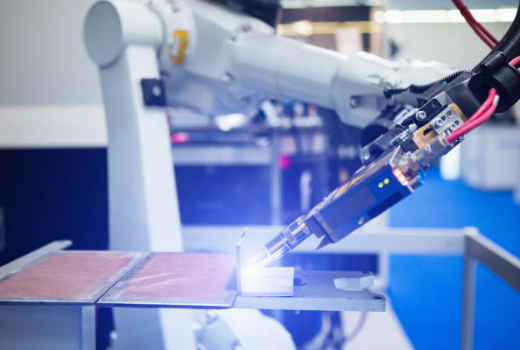

Laser cutting is the use of a high-power density laser beam to scan the surface of a material, heating the material to thousands to tens of thousands of degrees Celsius in a very short time, melting or vaporizing the material, and then using high-pressure gas to blow the melted or vaporized material away from the cutting seam, achieving the purpose of cutting the material. Laser cutting technology is widely used in the processing of metal and non-metallic materials, which can greatly reduce processing time, reduce processing costs, and improve workpiece quality.

Although almost all metal materials have a high reflectivity of infrared wave energy at room temperature, CO2 lasers emitting 10.6um beams in the far infrared band have been successfully applied in many metal laser cutting practices. The initial absorption rate of 10.6um laser beam by metal is only 0.5%~10%. However, when a focused laser beam with a power density exceeding 106w/cm2 is irradiated on the metal surface, it can quickly cause the surface to melt in microseconds. The absorption rate of most metals in the molten state increases sharply, generally increasing by 60% to 80%.

- Processing Technology of Carbon Steel Laser Cutting Machine

Modern laser cutting systems can cut carbon steel plates up to a maximum thickness of 20MM. The cutting seam of carbon steel can be controlled within a satisfactory width range using an oxidation melting cutting mechanism, and the cutting seam of thin plates can be narrowed to about 0.1MM.

- Processing Technology of Stainless Steel Laser Cutting Machine

Laser cutting is an effective machining tool for the manufacturing industry that utilizes stainless steel sheets as the main components. Under the strict control of the heat input measures in the laser cutting process, the cutting Heat-affected zone can be limited to become very small, thus effectively maintaining the good corrosion resistance of such materials.

- Processing Technology of Alloy Steel Laser Cutting Machine

Most alloy structural steel and alloy tool steel can achieve good edge cutting quality using laser cutting methods. Even for some high-strength materials, as long as the process parameters are properly controlled, a straight and slag free cutting edge can be obtained. However, for high-speed tool steel and hot mold steel containing tungsten, there may be corrosion and slag sticking during laser cutting.

- Processing Technology of Aluminum and Alloy Laser Cutting Machine

Aluminum cutting belongs to the melting cutting mechanism, and the auxiliary gas used is mainly used to blow away molten products from the cutting area, usually achieving good section quality. For some aluminum alloys, attention should be paid to preventing the occurrence of intergranular microcracks on the cutting surface.

- Processing Technology of Copper and Alloy Laser Cutting Machine

Pure copper (red copper) cannot be cut with CO2 laser beams due to its high reflectivity. Brass (copper alloy) uses higher laser power and auxiliary gases such as air or oxygen, which can cut thinner plates.

- Titanium and alloy laser cutting machine processing technology

Pure titanium can effectively couple and focus the thermal energy converted by laser beams. When oxygen is used as an auxiliary gas, the chemical reaction is intense and the cutting speed is fast. However, it is prone to generating an oxide layer on the cutting edge, which can cause overheating if not careful. For safety reasons, it is better to use air as an auxiliary gas to ensure cutting quality.

The commonly used titanium alloy laser cutting in the aviation industry has good quality. Although there may be a small amount of slag at the bottom of the cutting seam, it is easy to remove.

- Processing Technology of Nickel Alloy Laser Cutting Machine

Nickel based alloys, also known as superalloys, have many varieties. Most of them can be oxidized and melted for cutting.

Summary:

With the rapid development of the laser industry, related laser technology and laser products are also becoming increasingly mature. In the field of laser cutting machines, there is currently a dual force of YAG solid laser cutting machines and CO2 laser cutting machines, but fiber laser cutting machines have started to catch up.

About HGSTAR: HGSTAR is is a sub-brand of HGTECH.HGTECH the pioneer and leader of laser industrial application in China, and the authoritative provider of global laser processing solutions. We have comprehensively arranged laser intelligent machine, measurement and automation production lines, and smart factory construction to provide overall solutions for intelligent manufacturing.