Projects

How Laser Cutting Technology Helps Reduce Carbon Emissions

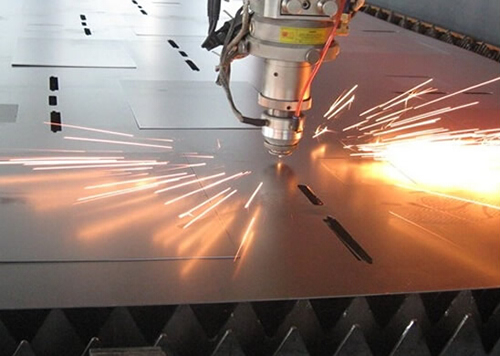

Laser processing has been highly sought after in recent years, rapidly replacing traditional processes, among which cleanliness and environmental protection are crucial factors, as laser processing achieves cleaner production processes. At the same time, with the breakthrough of high-power and high brightness laser technology, as well as the continuous progress of cutting technology, the dust generated by laser cutting will also be further reduced.

Air Cutting Process Reduces Smoke and Dust

The use of air cutting technology has achieved resource utilization and recycling from the perspective of gas consumables, while from the perspective of processing technology and the environment of the processing site, it conforms to the cleanliness of the production process. In the past, when cutting carbon steel with oxygen, a large amount of smoke and dust will be seen because of oxygen combustion support. Although there is some oxygen combustion support during air cutting, it is more similar to the principle of nitrogen cutting, relying on the energy of high-power laser itself to melt the material and then use High-pressure area to blow away the melt. Therefore, the smoke generated by air cutting is significantly reduced compared to oxygen cutting, which will greatly reduce the workload and power consumption of dust removal equipment.

In addition, the speed of air cutting is significantly improved compared to oxygen cutting, which is in line with the previously mentioned low-carbon energy consumption. It can be said that air cutting is an important change in the concept of green environmental protection for laser enterprises. Only this change can play a huge role in three aspects: energy low-carbon, resource recycling, and production cleaning.

Laser Technology Consumes Lless Eenergy

For laser equipment, how to achieve greater value through lower energy consumption is the key to achieving low-carbon energy consumption. For equipment integrators, due to the large number of power consuming components involved, the overall energy consumption is basically fixed during the same working time, making it impossible to directly save power like lasers. However, laser equipment is directly linked to user output. If it can be configured with the same power and energy consumption, and through the improvement of functional component performance and innovation of application technology, the efficiency and output of processing can be improved, it is also an important direction to achieve low-carbon energy consumption. In other words, producing the same output and creating the same value, laser technology consumes less energy.

Continuous Progress in High-Power Laser Technology

The implementation of low-carbon concept requires high-power laser technology as the foundation. In the past two to three kilowatts, due to the low laser energy, the effect of air cutting technology was not significant. Starting from 6000 watts, the advantages of air cutting in cutting carbon steel sheets have begun to emerge. Nowadays, the popularization of 20000 and 30000 watts allows the air cutting process to cover the vast majority of carbon steel processing needs on the market. Overall, the maturity of high-power laser technology and the improvement of high matching cutting head performance have enabled laser technology to perform better in reducing carbon emissions.