Projects

The Application Field Of Metal Coil After Laser Uncoiling

Laser cutting technology for coil materials

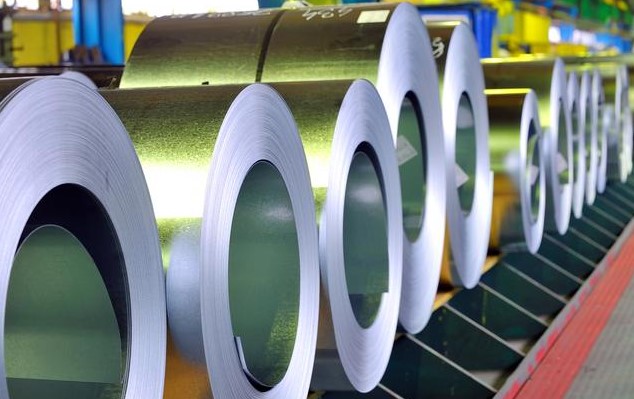

Metal products have a wide range of applications, especially for metal coils that are easy to transport. In the subsequent processing of coil materials, coil fed laser cutting machines and coil laser cutting are quite important, and we should have some understanding of them.

Typical application areas of metal coils

Metal coils are widely used in many industries, and their versatility and adaptability make them an important component of many processes and products. The following are several typical application areas:

1. Building and building materials: Metal coils can be used to make building materials, such as roofs and exterior wall panels. Its high strength and corrosion resistance make it an important component of building structures. In addition, metal coils can also be used to make doors and windows, anodized aluminum profiles, etc.

2. Automotive manufacturing: Metal coils play an important role in the automotive manufacturing process. It can be used to make car parts such as body shells, doors, and engine hoods, as well as components for chassis and suspension systems. The high strength and durability of metal coils enable them to withstand various pressures and vibrations during the operation of automobiles.

3. Electrical and electronic equipment: Metal coils are commonly used to manufacture the casings and components of electrical and electronic equipment. Its conductivity and thermal conductivity make it suitable for making components such as wires, connectors, and heat sinks. In addition, metal coils can also be used to manufacture battery cases, TV screen backboards, and so on.

4. Packaging and containers: Metal coils are widely used in the packaging and container manufacturing of products such as food, beverages, and cosmetics. Due to the excellent sealing and compression resistance of metal coils, they can maintain the freshness and quality of products, and prevent pollution and external factors from invading.

5. Energy and environmental protection: Metal coils can be used for the construction of solar panels, the manufacturing of energy equipment such as wind turbine brackets and gas storage tanks. At the same time, metal coils can also be used to manufacture components of environmental protection equipment and sewage treatment equipment, such as digestion tanks, filter materials, etc.

6. Other applications: In addition to the above application areas, metal coils are also widely used in metallurgy, petrochemicals, aerospace, medical equipment and other fields. Its diversity and plasticity make it suitable for various processes and products with different needs.