Projects

Coil Laser Cutting Technology Helps Metal Coil Processing

Application of coil laser cutting technology in metal coils

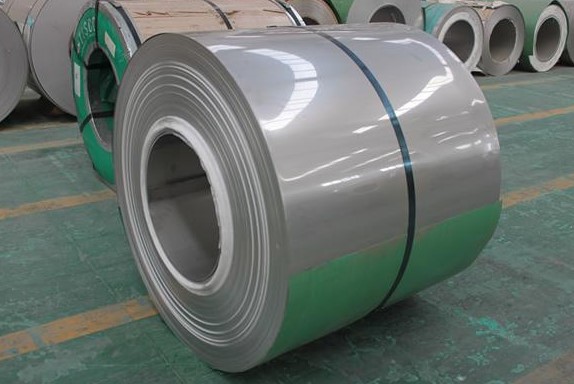

Metal coil is a product achieved through the processing and deformation of metal strips. The uncoiling and cutting technology of coil laser cutting machines and coil fed laser cutting system are widely welcomed in the industrial field due to their efficient and accurate characteristics. Laser cutting utilizes high-energy laser beams to instantaneously act on metal surfaces, achieving high-precision material separation. Compared with traditional mechanical cutting methods, laser cutting does not require contact with the material surface, avoiding deformation of the coil caused by mechanical stress, and ensuring the smoothness and verticality of the cutting edge. It is worth mentioning that the coil laser cutting machine has an extremely fast processing speed and can achieve automated operations, greatly improving production efficiency.

Working principle of metal coils

The working principle can be summarized as the following steps:

1. Material selection: Metal coils can be made of various types of metal materials, such as iron, aluminum, stainless steel, etc. The selection of appropriate materials has a significant impact on the performance and service life of the coil.

2. Raw material processing: The production of metal coils usually requires multiple processes, with the most important step being the pre-treatment of the raw metal material. This includes steps such as surface treatment, cutting, and cleaning to ensure that the material quality and dimensions meet the requirements.

3. Rolling: In the production process of metal coils, the original metal strip is rolled, stretched, and bent using equipment such as a rolling mill or coiling machine to continuously deform and refine, forming a certain width and thickness of metal coils.

4. Processing and shaping: After being rolled, the metal coil needs to be further processed and shaped to meet the requirements of special purposes. This involves laser cutting, punching, welding and other operations, as well as surface treatment of the coil, such as polishing, spraying, cleaning, etc.

5. Packaging and transportation: Finally, the metal coil needs to be packaged and transported to ensure that it is not damaged during transportation and storage. Proper packaging can reduce the friction and collision of metal coils during handling and transportation, thereby protecting their integrity and quality.

Supplement and summary

During the uncoiling process of metal coils, coiling laser cutting machines can quickly and accurately complete continuous cutting of a large amount of materials, reducing manual intervention and material waste. In addition, laser cutting machines also have the advantage of environmental protection, as they do not produce any harmful substances during the processing, in line with the concept of modern green manufacturing. In summary, laser uncoiling and cutting technology has become an ideal choice in the field of metal coil processing due to its advantages of high efficiency, high precision, and environmental protection, bringing revolutionary changes to industrial production.