Projects

Automated Laser Welding Solution for Metal Bipolar Plates, Empowering the Fuel Cell Industry

Hydrogen fuel cells are hailed as the fourth generation of power generation technology following hydropower, thermal power, and nuclear power. Through electrochemical reactions, they efficiently generate electricity from hydrogen or other fuels, producing only electricity, water, and heat as byproducts. They offer advantages such as high efficiency, minimal environmental pollution, and high reliability, with extremely broad prospects for application.

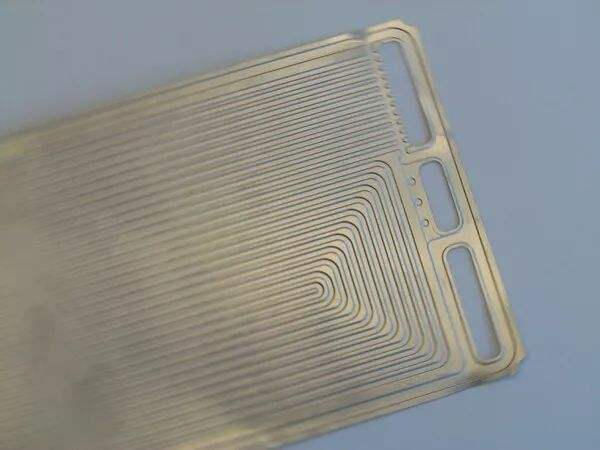

The key component of a hydrogen fuel cell, is formed by stacking multiple individual cells. Each cell primarily consists of components such as an anode plate, cathode plate, membrane electrode assembly, gas diffusion layer, and seals. Bipolar plates, as crucial components of the stack, require high electrical conductivity, good thermal conductivity, high hydrophobicity, low heat capacity, excellent corrosion resistance, good gas tightness, and resistance to vibration. Their performance directly affects the overall quality of the fuel cell stack.

The bipolar plate is composed of anode and cathode plates welded together, and the stability and gas tightness of these welds directly affect the electrical efficiency, performance, and safety of the fuel cell stack.

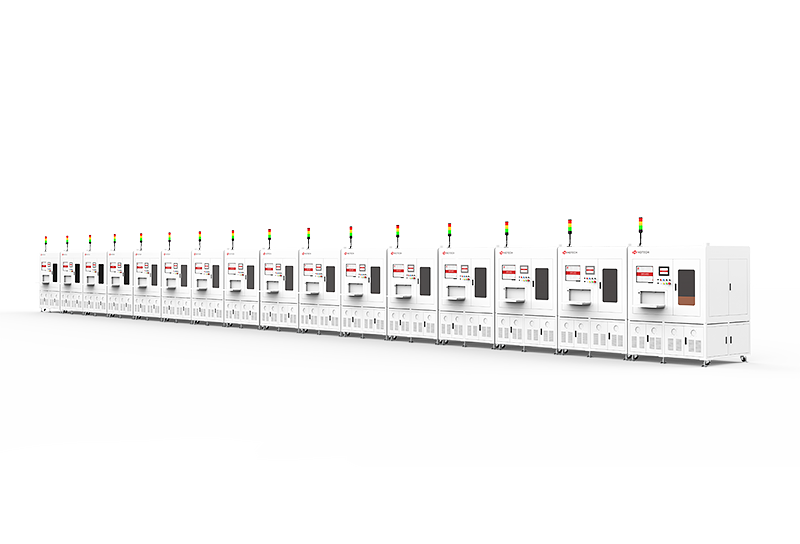

Although nowadays we can easily achieve automated laser welding of metal bipolar plates, just over a decade ago, domestic practices were still at the manual stage of using adhesive strips and glue to bond metal plates, which was highly inefficient. Today, placing metal bipolar plates into fully automated laser welding equipment allows for a welding operation to be completed in just 10 seconds.

Laser welding is the process of irradiating the surface of metals with a high-energy density laser beam. Under the instantaneous high-temperature effect of the laser beam, the metal melts and solidifies to form a weld seam. This method offers advantages such as high energy, low deformation, fast welding speed, narrow heat-affected zone, and good accessibility.

Based on extensive experience in the field of automatic laser welding, HGTECH has developed intelligent manufacturing solutions. HGTECH have introduced an automated production line for hydrogen fuel cell metal bipolar plates, integrating functions like automatic loading and unloading, laser welding, inspection, coding, real-time data upload, remote monitoring of products, and information traceability. This solution not only effectively ensures the welding quality and performance of the bipolar plates but also significantly improves operational efficiency.

- Automatic loading + visual positioning

- Fully automatic robotic arm loading accuracy±0.02mm;

- Capable of welding metal bipolar plates up to maximum size of 500mmX300mm, covering most products available on the market;

- Each station is independently designed, modular, and flexible; Can be customized to meet different needs;

- Equipped with online inspection function to achieve full material inspection.