Projects

Automotive Electronics IGBT Laser Soldering

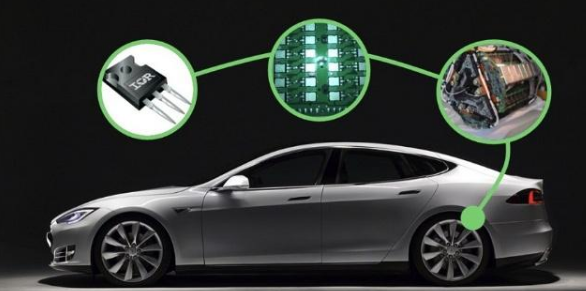

Anyone who has been in the automotive electronics industry knows that the IGBT module is the core component that controls the current output during acceleration of electric vehicles and the current input during braking energy feedback. So what is an IGBT? IGBT is the abbreviation of Insulated Gate Bipolar Transistor, which is a composite fully controlled voltage-driven power semiconductor device composed of BJT (bipolar transistor) and MOS (insulated gate field effect transistor). It has the advantages of both the high input impedance of MOSFET and the low on-state voltage drop of GTR. It is very suitable for use in converter systems with a DC voltage of 600V or above, such as AC motors, inverters, switching power supplies, lighting circuits, traction drives, and other fields. The topic of this chapter is only to explain the application of laser soldering in automotive electronic IGBT modules.

Automotive electronics IGBT laser soldering

IGBT module is a modular semiconductor product formed by IGBT (insulated gate bipolar transistor chip) and FWD (freewheeling diode chip) through a specific circuit bridge package; the packaged IGBT module is directly used in inverters, UPS uninterruptible power supplies and other equipment; IGBT module has the characteristics of energy saving, easy installation and maintenance, stable heat dissipation, etc.; most of the products sold on the market are such modular products, and the IGBT generally refers to IGBT modules; with the advancement of energy saving and environmental protection concepts, such products will become more and more common in the market.

Before the IGBT module is packaged in the shell, the IGBT chip and the diode chip are first welded to the DBC substrate through welding pieces, and then the DBC with the welded chip is bonded, and then the secondary welding is performed. In this process, the welded sub-unit is first cleaned to prevent the sub-unit from being oxidized, and then the sub-unit, electrode, welding piece and welding ring are welded to the heat dissipation base of aluminum silicon carbide through equipment.

IGBT module laser welding

Analysis of factors affecting IGBT void rate in secondary welding process

1. Solder

Currently, the materials of solder sheets and solder rings used contain Sn, Pb and Ag, there is no flux, and the solder is ensured not to be oxidized before welding.

2. Welding temperature

During the welding process, the IGBT to be welded is loaded on a tray, and the motor drag system is used to make it run in the heating zone, cooling zone, vacuum pressure holding zone, etc. in turn. During the welding process, the appropriate welding temperature can be selected according to the melting point temperature of the solder, and the welding temperature is set completely according to the standard process documents.