News

2021 best handheld fiber laser welding machine in the united states

The handheld fiber laser welding machine emits a pulsed laser with a wavelength of 1064nm after beam expansion, reflection, and focus to radiate the surface of the workpiece. Heat conduction transports surface heat to the interior, and digitalization precisely controls the width, energy, and peak power of the laser pulse.

The workpiece is melted to form a specific molten pool using parameters such as repetition frequency, in order to realize laser welding of the workpiece and complete precision welding that the traditional TIG welder & MIG welder cannot achieve.

The benefits of a fiber laser welding system include high energy concentration, no pollution, small solder joints, a wide range of weldable materials, high applicability, high efficiency, and fast welding. Products with stringent welding seam requirements are welded with laser welding equipment, which not only has small weld seams but also does not require solder. The welding path of a laser welding system can be manually programmed.

he hand-held fiber laser welding system is capable of welding difficult-to-access parts as well as non-contact remote welding with high sensitivity. The fiber laser beam welding system is simple to install and can stop welding at room temperature or under special conditions. The laser’s beam will not shift as it passes through the electromagnetic field. The laser can weld in vacuum, air, and certain gas environments, and it can stop welding when it passes through glass or other transparent to the beam materials.

The laser system, laser power supply system, console and fiber transmission system, industrial television observation system (optional), special cooling system, and other components comprise the hand-held fiber laser welding machine.

Optical Fiber Transmission System

Transmission fiber: optional according to welding spot requirements;

Minimum focus spot diameter: 0.3mm;

Working distance of objective lens: 70mm;

Focus adjustment range: 20mm.

Operation Console (Optional)

Stainless steel is used for the work surface. The work surface space can include a bracket for the display and measuring instruments; the volume is small, and the layout of the work surface can be determined based on user needs, such as the installation of a manual lifting mechanism.

CCD observation system with a black and white side-axis.

Three-channel black-and-white CCD camera with side-axis placement and a 14-inch high-resolution black-and-white monitor.

Dedicated Laser Cooling System

Patented design, dual-circulation cooling, and temperature control system with precision. The coil structure is made entirely of titanium alloy. To ensure water quality, the evaporator, water tank, and pump body are all made of high-strength non-metallic materials or stainless steel. The imported low-noise jet self-priming centrifugal pump circulates and cools the laser. The refrigeration compressor cools the circulating water using a secondary cycle.

Because the hand-held laser welding machine generates heat while in operation, a laser chiller must be configured for cooling and heat dissipation. The laser chiller’s stability has an impact on the laser welding machine’s normal operation. S&A is the market’s leading chiller brand for cooling handheld laser welding machines at the moment. The S&A brand CW series laser chiller, with its innovative refrigeration technology and consistent quality advantages, has gradually evolved into a standard product of mass modular production that is highly regarded by manufacturers of laser industry production equipment.

Laser Power System

The handheld laser welder’s pulsed laser power supply is a specialized power supply system designed to power the pulsed xenon lamp. It is made up of several circuits, including a charging circuit, an energy storage unit, a discharging circuit, a trigger/pre-ignition circuit, a logic control circuit, and an electrical operation circuit.

The charging circuit’s function is to provide charging power to the energy storage unit’s large-capacity capacitors. Constant current charging is the best charging method based on the characteristics of energy storage capacitors. This power supply employs an LC constant current source, which is a constant current charging circuit. This circuit has a simple structure, easy control, high reliability, and consistent benefits such as good flow characteristics.

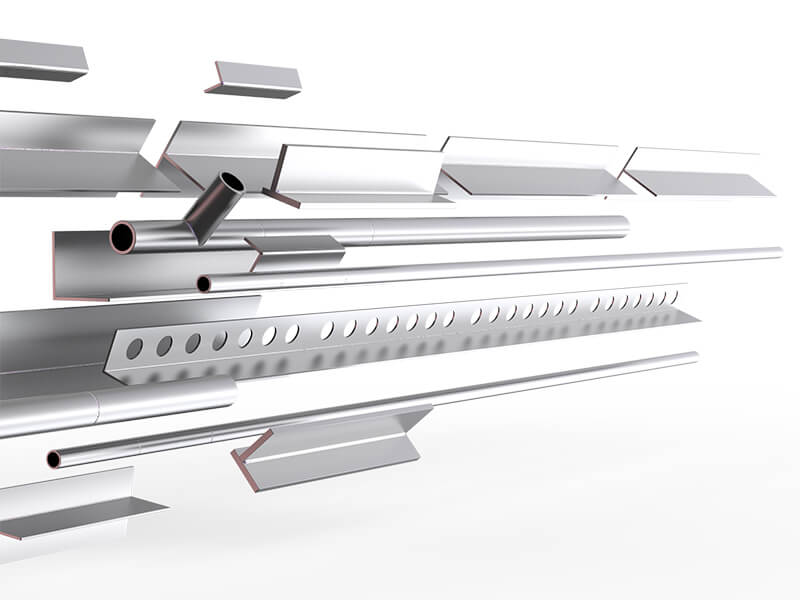

Parts for a Handheld Laser Welding Machine

Projects for Handheld Laser Welding

Fiber laser welding machines are commonly used for tailor welding and metal repair welding. Laser welding works by using high-energy laser pulses to heat a small area of the material. After melting, high-temperature energy diffuses from the material’s surface to the interior, forming a specific molten pool. Because the material used in the entire process is extremely hot, how should we use a handheld laser welder safely?

Handheld Laser Welding Safety Tips

Handheld fiber laser welders are commonly used for tailor welding and metal repair welding. Because the materials are in a high temperature state during the laser welding process, how should we use the handheld laser welder safely?

1. If there is an emergency during the operation, such as a water leak or an abnormal laser sound, you must immediately press the emergency stop button and turn off the power supply.

2. Prior to operation, the laser welding’s external circulating water switch must be turned on. Because the laser system uses water cooling, the laser power supply uses air cooling. It is strictly forbidden to begin working if the cooling system fails.

3. It is strictly forbidden to touch any of the machine’s circuit components while it is in operation. The circuit is in a high voltage and high current state when the laser welding machine is operating. The machine cannot be operated by untrained personnel.

4. It is strictly forbidden to directly use the eye scanning laser when the laser is working to avoid eye injury. It is forbidden to use external equipment to reflect laser light during laser work.

5. Do not disassemble any parts of the machine at will, and do not weld when the safety door of the machine is opened, and do not aim the laser head at the equipment parts.

6. Do not place flammable and explosive materials where the laser light path or laser beam can be irradiated to avoid fire and explosion.