Projects

Fitness Equipment Solutions

Fitness equipment is a product that people who pursue fashion and love life often come into contact with. In recent years, the fitness equipment industry has become more and more demanding as the demand for Significant increase in demand for aerobic, strength equipment two categories of products, user experience standards are increasingly high, gym investors in the purchase of fitness equipment products pay more attention to the details of the product.

In the fitness equipment products, pipe application is very common, many connections are into the coherent line butt, the traditional processing method is to use band saw and drilling machine, special milling machine to achieve, such a way can not guarantee the beauty, but also can not guarantee the accuracy, but also occupy a lot of labor costs and material clamping, transit time costs.

Recommended solutions

Due to the processing of more tubes in the fitness equipment industry, it is often necessary to use the cutting and perforating process of tubes. The laser can cut traditional or shaped tubes such as round tubes, square tubes, oval tubes, bread tubes, D-shaped tubes, etc. With the advantages of high flexibility, high precision, high efficiency and short production cycle, it has become a standard equipment in the manufacturing process of fitness equipment industry.

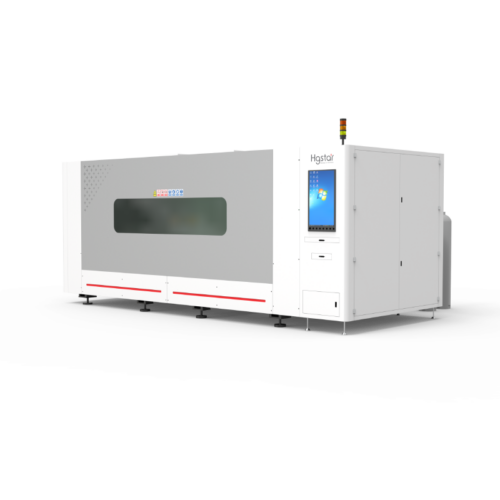

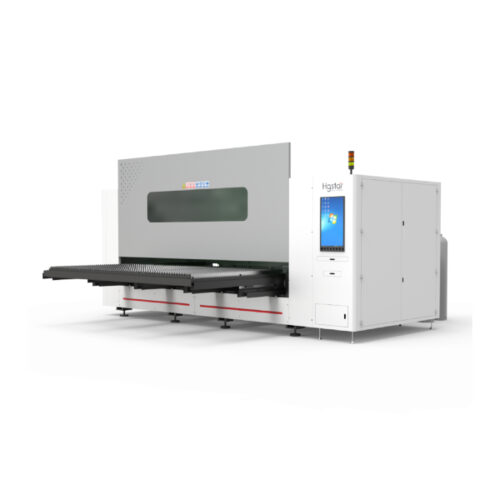

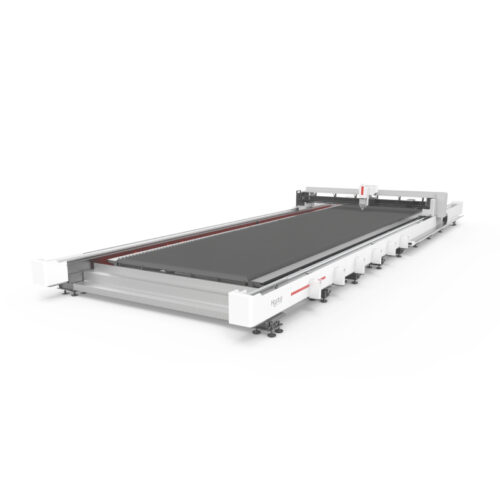

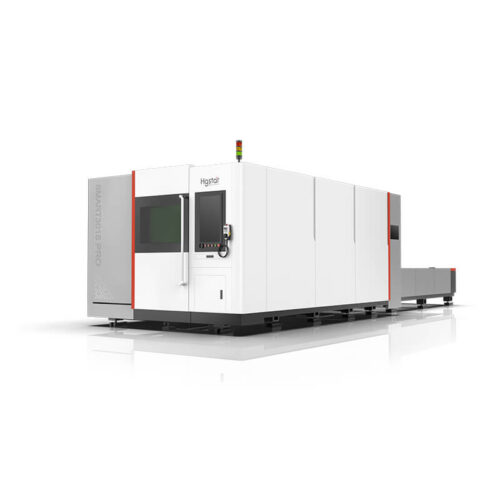

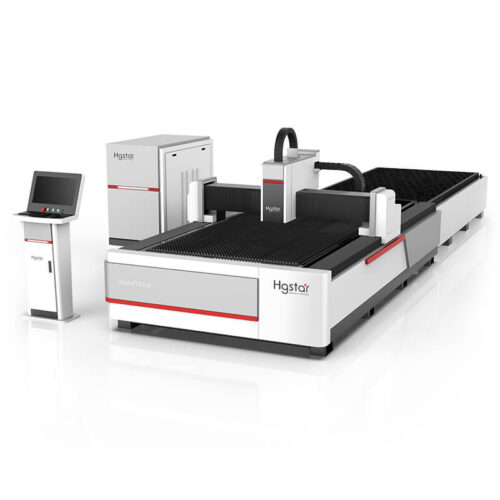

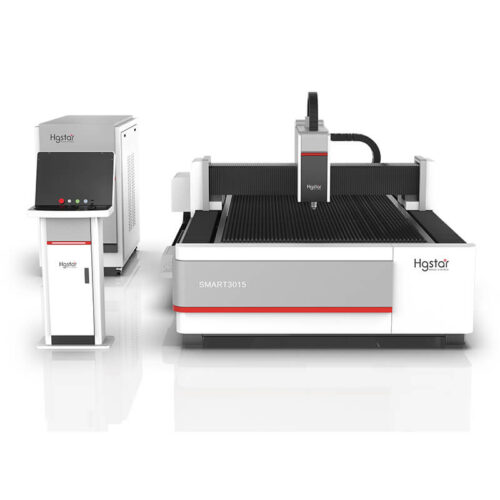

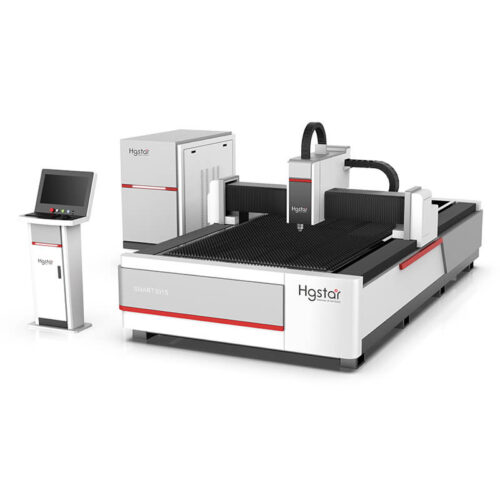

HG Laser LT7535 automatic pipe production line equipment (optional automatic loading and unloading, bevel cutting function and robot automatic palletizing)

● Automatic loading and unloading in bundles and automatic palletizing by robot as an option, which can completely say goodbye to high intensity and high load labor.

● Fully flexible cutting, high efficiency processing of various tracks and tubes, no secondary positioning and high precision.

● Equipped with laser marking function, which provides direct convenience for production management.

●New standard equipped with Germany SIEMENS 840Dsl full set of CNC system, high dynamic response and good stability.

Processing advantages

● Reduce production cost, reduce material conversion, replace traditional cutting method, no clamping, no secondary processing of workpiece

● Good processing effect, fully flexible processing, can cut various trajectory contours

The laser marking function is good for product tracking and record, and the marking function can be used to mark the product drawing number and production number, which is convenient for production management, warehouse management and logistics distribution.

● Increase the added value, which can make the product look higher grade. Enhance the brand awareness of the product

● High precision equipment, full numerical control processing mode, high precision and low clearance, which can provide great convenience for the next robotic automatic welding line.

● Stable and reliable performance, 24 hours continuous operation, maintenance-free laser time up to 20,000 hours or more

● Wide temperature range (5℃-45℃), widely used in various industries

● High degree of automation, the optional automatic loading and unloading function of the pipe cutting machine can realize fully automatic production, automatic bundle loading, automatic clamping, automatic length measurement, automatic unloading, and also the optional robot automatic sorting and palletizing.