Projects

Coil Feed Laser Blanking Lines Industry Applications

Introduction

Laser technology, as one of the most advanced manufacturing and processing technologies in the world today, has been widely applied in industrial production, communication, information processing, medical beauty, 3D sensing, military, cultural education, and scientific research.

In the previous article, we talked about the advantages of laser cutting production lines. Today, we will learn in detail about the industry applications of coil feeding laser punching lines as intelligent cutting tools.

Application of coil fed laser punching line in various industries

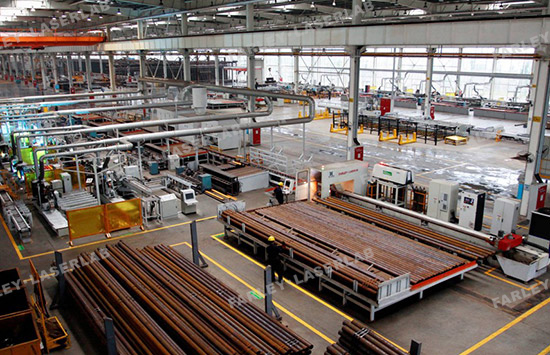

The coil fed laser punching line is an efficient and high-precision automated processing equipment widely used in the processing and production of metal materials. It uses a laser punching system to control the laser beam to cut metal materials, achieving high-speed and high-quality processing, while also having advantages such as automation, high efficiency, and saving labor costs.

Here are some common industry applications of coil fed laser cutting lines:

Automotive manufacturing: In the automotive manufacturing industry, laser cutting production lines are widely used for cutting and processing of automotive components, such as engine parts, chassis parts, etc. Laser cutting technology can achieve high-quality cutting of complex shaped parts, improve production efficiency and product quality.

Mechanical manufacturing: In the mechanical manufacturing industry, laser cutting production lines are used to process various metal parts, such as gears, bearings, flanges, etc. Laser cutting technology can achieve high-precision cutting of high-strength and high hardness metal materials, improving product performance and service life.

Electronic manufacturing: In the electronic manufacturing industry, laser cutting production lines are used to process various electronic components, such as circuit boards, batteries, etc. The coil laser cutting machine can achieve precise cutting of small parts, improving product performance and reliability.

Household appliance manufacturing: In the household appliance manufacturing industry, laser cutting production lines are used to process various household appliance components, such as air conditioning casings, refrigerator liners, etc. The coil laser cutting machine can achieve high-quality cutting of various materials and shaped parts, improving production efficiency and product quality.

Summary

The application technology of coil fed laser cutting lines is becoming increasingly mature, and its advantages are obvious, which can meet the processing needs of various fields. With the development of technology and continuous improvement, it is believed that the application scope and market prospects of laser coil flattening and automatic feeding production lines will become increasingly broad in the future.