Projects

Development Trends of 3D Five Axis Laser Technology

What are the social impact environments for the development of five axis lasers?

Widespread demand brought by downstream applications

The 3D five axis laser cutting technology has been around since the 1990s, and the initial market demand was not high. But with the emergence and application of automotive hot forming technology, the situation of low market demand has changed, and the market demand is developing explosively.

Major enterprises’ R&D investment continues to increase

The 3D five axis laser cutting machine to some extent represents the highest technological level of global CNC machine tools, and has broad application prospects and market prospects. Therefore, major enterprises are increasing their research and development investment to seize the market.

Technological progress

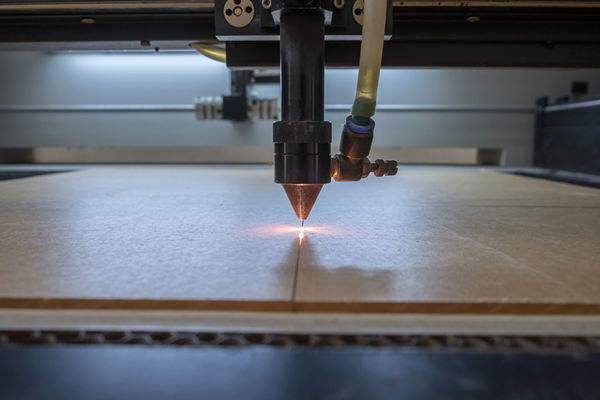

Major manufacturers actively respond to customer needs, while also continuously carrying out technological iterations and upgrades to maintain the competitiveness of their products. The core component cutting head of the product gradually meets the needs of high-performance and lightweight, with functions such as automatic focusing, three-point positioning, rapid perforation, and intelligent collision prevention, truly achieving intelligent, efficient, and low energy consumption flexible processing. Technological progress has further expanded the scope of application.

Support from national policies

With the recovery of the global economy in the post pandemic era, investment in manufacturing has significantly accelerated, and the prosperity of industries such as laser equipment and industrial automation continues to improve. Laser processing technology, with its advantages of fast speed, high accuracy, and good processing quality, has gradually replaced traditional processing methods and become one of the key high-tech supported and promoted by all countries.

Risks faced by industry development

- Macroeconomic fluctuation risk

The overall economic development situation in the world today is not stable. The market demand for three-dimensional and five axis laser processing equipment is greatly affected by the macroeconomic situation. If there is downward pressure on the macroeconomic situation, the demand for downstream manufacturing capacity of laser cutting equipment will slow down, and the demand for laser cutting equipment in downstream industries such as automobiles, aerospace, molds, and household appliances will decrease, which will have a negative impact on the sustained growth of the industry.

- Market competition intensifies risks

The 3D five axis laser cutting equipment industry is still in a period of rapid expansion. This field will usher in a wave of capital investment, with the participation of numerous enterprises leading to increasingly fierce market competition. Only by having strong competitive advantages in terms of business scale, technology and process level, product quality, etc., can we gain more market share. If a company fails to further enhance its core competitiveness and maintain a leading advantage in market competition, it will face the risk of shrinking market share and decreasing profitability.

- Risk of COVID-19

Affected by the COVID-19 that began to break out globally in the middle and late January 2020, all walks of life have been greatly impacted. During the COVID-19, the business prospect of downstream manufacturing industry was unclear, and the demand of downstream customers of 3D five axis laser cutting equipment declined. Resulting in a certain impact on the industry scale. In the second half of 2020, with the global COVID-19 gradually under control, the industry began to recover. However, if the global COVID-19 epidemic is repeated, not only will it be detrimental to the stable operation of manufacturers, but also the demand of downstream customers of laser cutting equipment may change significantly, which will have a negative impact on the sustainable and stable growth of the industry.

- Core raw material risks

Most manufacturers in the industry still do not have significant raw material supply capabilities and mainly rely on external procurement. If the market for lasers, cutting heads, and other products is in short supply or there are adverse changes in related industries, it will lead to an increase in the procurement cost or supply shortage of main raw materials for the company, which will have a negative impact on the company’s production and operation, and thus affect the overall stability of the industry.

- Technological innovation and risk of technological talent loss

The manufacturing industry of three-dimensional and five axis laser equipment belongs to a technology intensive industry. With the increasing demand for product customization and technical performance differentiation from downstream customers, higher requirements have been put forward for companies in the industry in terms of technical reserves, continuous research and development, and differentiated service capabilities; Meanwhile, with the increasing competition in the field of laser cutting equipment, the upgrading and iteration of laser cutting related technologies are fast.

About HGSTAR: HGSTAR is is a sub-brand of HGTECH.HGTECH the pioneer and leader of laser industrial application in China, and the authoritative provider of global laser processing solutions. We have comprehensively arranged laser intelligent machine, measurement and automation production lines, and smart factory construction to provide overall solutions for intelligent manufacturing.