Projects

Application Of Groove Laser Cutting Machine In Shipbuilding Field

Introduction

Every giant ship is a pearl at sea, behind which lies the endless wisdom and sweat of the shipbuilding industry. Among them, the large groove laser cutting machine has injected new vitality into shipbuilding with its excellent performance and accuracy, becoming an important force in promoting the development of this industry.

Ensure the stability of the ship’s structure

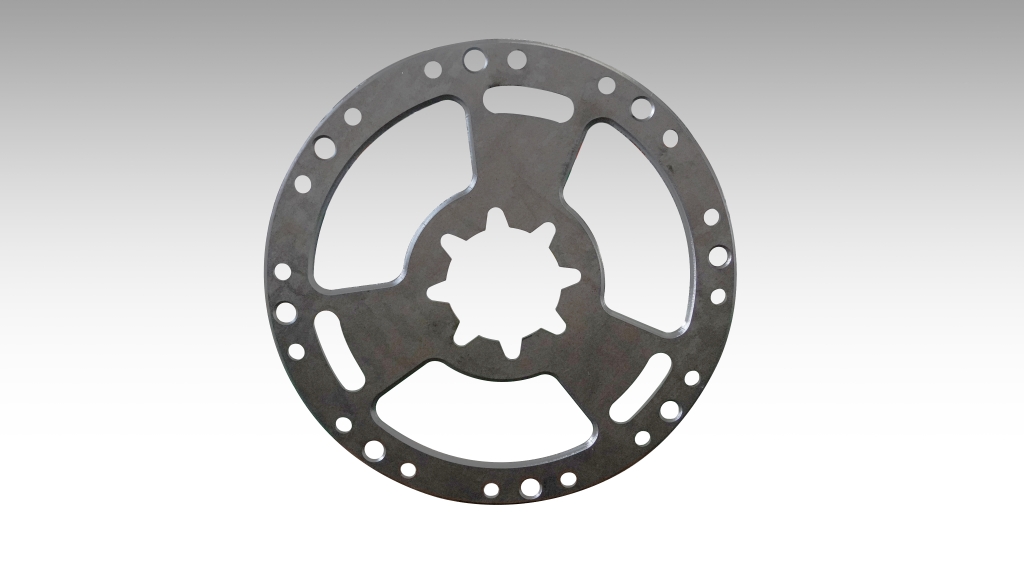

As a means of water transportation, the safety and stability of the structure of ships are crucial. In the process of shipbuilding, groove processing is a key link in the welding process, which directly affects the overall quality of the ship. The groove laser cutting machine uses a laser beam for non-contact cutting, which can achieve high-precision groove processing and ensure the quality and strength of welded joints. Whether it is the cutting of ship hull panels or the groove processing of complex components, the groove laser cutting machine can be completed with excellent accuracy, providing strong guarantees for the safe navigation of ships.

Shorten ship manufacturing cycle

Ship manufacturing is a massive and complex project that requires a significant investment of manpower and resources. In order to improve production efficiency and shorten manufacturing cycles, groove laser cutting machines have played an important role. Its efficient cutting speed and automated operation mode make the groove processing process faster and more accurate. Compared with traditional mechanical cutting, laser cutting not only has a faster speed, but also reduces manual intervention, lowers human error rates, and significantly improves production efficiency.

Meeting the diverse needs of shipbuilding

The shipbuilding industry has an increasing demand for product diversity and personalization. The requirements for groove processing vary for different types of ships and components in different parts. The groove laser cutting machine, with its flexible adaptability, can meet these diverse needs. Whether it is the cutting of large ship hull panels or the precise processing of small components, laser cutting machines can easily handle it, providing more possibilities for shipbuilding.

Assist in the green development of shipbuilding industry

With the increasing awareness of environmental protection, the shipbuilding industry is also actively exploring the path of green development. As an environmentally friendly and energy-saving cutting equipment, the groove laser cutting machine has made contributions to the green development of the shipbuilding industry. During its cutting process, there is no need to use chemicals such as coolant and cutting fluid, reducing waste liquid emissions and environmental pollution. Meanwhile, the energy consumption of laser cutting is relatively low, which helps to reduce energy consumption and carbon emissions in the shipbuilding process.

Epilogue

The application of groove laser cutting machines in the field of shipbuilding has injected new vitality into this ancient and dynamic industry with its advantages of high precision, high efficiency, flexible adaptation, and environmental protection and energy conservation. With the continuous progress of technology and the expansion of application fields, we have reason to believe that groove laser cutting machines will bring more innovation and breakthroughs to shipbuilding in the future, jointly writing a new chapter in ocean exploration.