Projects

HGTECH’s 2024 Exhibitions: Unveiling Innovative Laser Technologies

From May 6th to May 9th, HGTECH will participate in the AUTOMATE Show, held in Chicago, USA. The exhibition has grown to become the largest and most professional robotics and automation technology event in North America. HGTECH will showcase our automatic product line at the booth, demonstrating cutting-edge automation equipment and technological achievements to the world.

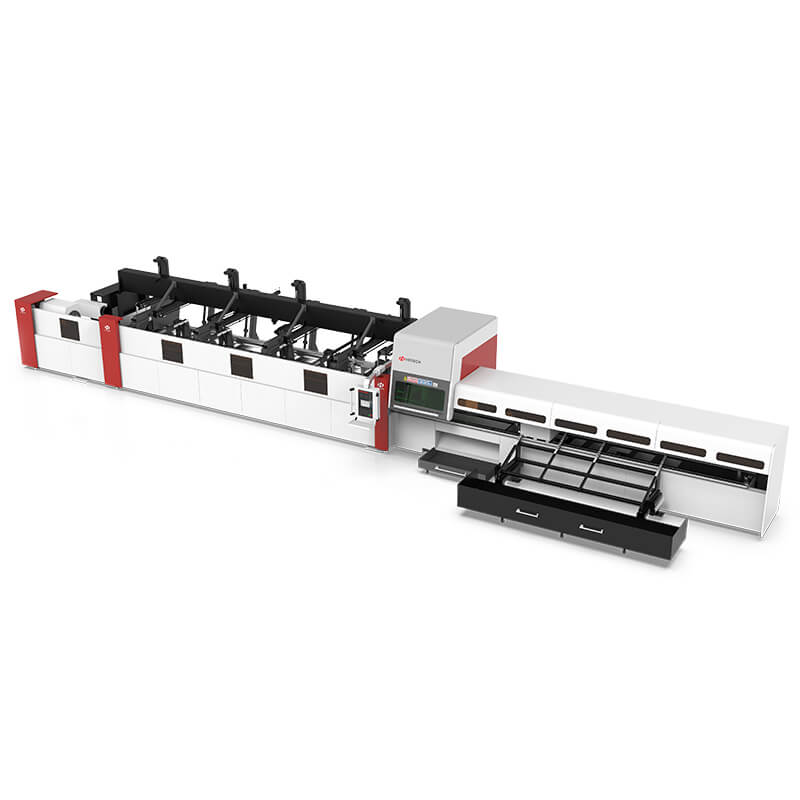

From May 7th to May 11th, HGTECH will showcase SMART 3015 Pro Laser Cutting Machine, SMART HW 2000 Handheld Laser Welding Machine, TALOS 6535 Tube Laser Cutting Machine at Feimec in Brazil. Feimec, the São Paulo Industrial Exhibition, can be seen as the most important platform for Chinese machinery equipment to enter the Brazilian market and even the whole South America. HGTECH will seize this opportunity to not only bring our cutting-edge equipment to the world but also engage in discussions on future trends in industrial development.

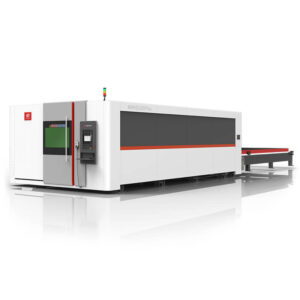

Product: SMART 3015 Pro Laser Cutting Machine

Product Highlight:

- Autofocus laser cutting head without manual focusing

- Small deformation, low vibration, and extremely high precision

- Effectively reduce beam speed, make cutting and machine more stable

- Active anti-collision function, save maintenance cost

Product: SMART HW 2000 Handheld Laser Welding Machine

Product Highlight:

- Widely used in industrial hardware manufacturing

- Compact design

- System with smart multiple alerts to guide for trouble shooting, automatic beam lock-up when no welding target attached in high security

- A variety of angle nozzles choice to ensure the welding quality fits different applications

- Super large HMI interactive interface

- Large cutting load, high precision, can achieve zero tailing cutting

- Equipped with fully enclosed machine tool cover, the overall safety protection of the machine tool meets the highest international standards

- Modular design, can be customized according to customer requirements.

- UHP / 20000W

- Acceleration: 3.0G; Max. Positioning Linkage Speed:168m/min

- Continuous production; Stable quality; Remote diagnosis

- Intelligent anti-Collision; Safe and environmental friendly

- Equipped with MES data interface as standard, supporting the expansion of metal sheet automation material library

- Acceleration: 3.0G; Max. Positioning Linkage Speed:168m/min

- Continuous production; Stable quality; Remote diagnosis

- Intelligent anti-Collision; Safe and environmental friendly

- Meet 100% metal material processing needs

- Reduced procurement costs and reduced maintenance costs

- Auto Focusing Cutting Head+Aviation Grade Compression Beam+Patent Hollow Bed

- Auto focusing, high precision

- Energy conservation, environmental-friendly design

- Stability of sheet batch cutting

HGTECH is committed to delivering cutting-edge laser solutions to its global clientele. These exhibitions offer a unique opportunity for attendees to witness firsthand the technological prowess that sets HGTECH apart in the laser industry. Whether at the IMTEX Forming Exhibition in India or the SPIE Photonics-west Exhibition in the United States, HGTECH aims to showcase its latest technologies, solidifying its position as a leader in the laser industry. Stay tuned for exciting demonstrations and in-depth discussions.

From March 7th to March 9th, HGTECH will be attending ITIF Asia in Pakistan

One of the largest technology and information technology exhibitions in Asia. HGTECH will showcase its latest laser cutting and welding solutions at the booth, bringing innovation and efficient production tools to customers in Pakistan and the surrounding regions.

From March 20th to March 22nd, HGTECH will be exhibiting at Laser world of photonics china in Shanghai

Featuring its highly anticipated intelligent equipment lineup, including online laser cleaning systems for tire molds, high-end wafer laser cutting equipment, high-brightness laser processing solutions, and laser welding equipment for flat wire motors.

Product: Tire Mold Intelligent Laser Cleaning Equipment

-Improve production efficiency and reduce economic costs

-Equipped with LIDAR which enables detection

-Enable automatic cleaning by the robot with 3D machine vision the safety of the robot

-Equipped with anti-collision sensors, which can effectively protect the safety of the robot

-Collect smoke and dust generated to protect the surrounding working environment

Product: High-Brightness Laser Processing Solutions

-Laser polishing, shiny and free of impurities, effectively improving logo recognition

-Simple process, high cost-effectiveness, significantly optimizing the process of laptop production

-Strong compatibility, compatible with multiple sizes, patterns, and materials

-Adsorption platform ensures product flatness, and water cooling system ensures processing stability

Product: Laser Welding Equipment For Flat Wire Motors

-Significantly reduce welding spatter and porosity, improve processing efficiency, 0.3S/point (including visual positioning)

-Can achieve one-time welding of products without the need for rotation

-Fully automatic clamping of welding fixtures to ensure consistency in pin end position

-Can be configured with dual workstations or online, meeting different production conditions

From March 25th to March 28th, HGTECH will be present at GLOBAL INDUSTRIE in France

Showcasing its smart series laser cutting machines. As one of the largest industrial exhibitions in Europe, GLOBAL INDUSTRIE will provide HGTECH with an excellent platform to showcase its latest technology and innovative products.

Product: Smart Series Laser Cutting Machines

-The software automatically adjusts the focusing lens to achieve automatic perforating and cutting of various thickness plates. The speed of automatically adjusting the focus lens is ten times faster than manual adjustment.

-The high strength machine bed is treated with a stress relief annealing method at 600°C, which results in a strong structure rigidity; integral mechanical structures have the advantages of small deformation, low vibration, and extremely high precision.

-JAPAN Fuji servo high speed srvo motor.Effectively reduce beam speed, make cutting and machine more stable, and extend machine life.

-Active Anti-collision Function, Effectively reduce the damage rate of laser heads, help you save maintenance cost.

-Aluminum monolithic cast beam, light weight, high strength, no deformation Light crossbeams, which are molded and framed using integral steel mold and die-casting technology, give equipment a high operation speed, improving processing efficiency and quality.

HGTECH looks forward to meeting global customers and partners at these trade shows, demonstrating its latest technology, innovative products, and vision for collaboration with customers. HGTECH will continue to provide excellent laser cutting and welding solutions to customers worldwide, promoting the development and progress of the global manufacturing industry.

HGTECH, a leading player in the field of laser technology, is gearing up for its participation in two highly anticipated international exhibitions in January 2024, unveiling the latest advancements in laser processing and marking technologies.

IMTEX Forming Exhibition – January 19th to 23rd, 2024

From January 19th to 23rd, HGTECH will be showcasing its cutting-edge SMART3015 pro laser cutting machine at the IMTEX Forming Exhibition in India. Visit our booth at Hall 5, C134, and explore the innovative solutions that are revolutionizing laser technology. India, known for its rich cultural heritage and technological advancements, provides an ideal backdrop for HGTECH to connect with industry leaders and enthusiasts alike.

Product: SMART3015 Pro Laser Cutting Machine

-Without manual focusing, autofocus laser cutting head

-Security and non-pollution

-Fiber lasers source

-Effectively reduce beam speed, make cutting and machine more stable, and extend machine life

SPIE Photonics-west Exhibition – January 30th to February 1st, 2024

Following this, HGTECH will be participating in the SPIE Photonics-west Exhibition in the United States from January 30th to February 1st. We’ll be showcasing our PCB dual-head laser marking machine, LCB10C, at Booth 1872. The exhibition, held in the vibrant region of the American West, brings together pioneers and innovators in the field of photonics. It provides an excellent platform for HGTECH to engage with professionals and enthusiasts in the United States, a hub of technological innovation.

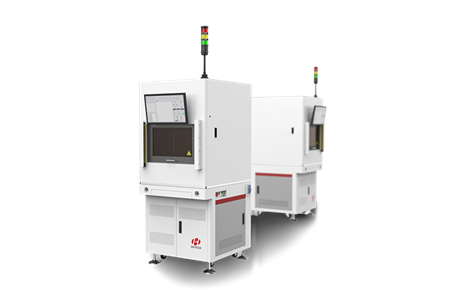

Product: PCB Dual-Head Laser Marking Machine

-High-performance CO2 / Fiber laser has high-quality laser beam, small focusing spots and well-distributed power.

-The high-pixel CCD camera makes automatic positioning, identification and feedback reporting come true.

-Gantry structure and synchronous transmission guideways ensure the stable and precision performance.

-The function of automatic focusing and track width adjusting are designed to match up different production line.