Projects

HGTECH Structural Steel Cutting Equipment: Forging an Efficient Manufacturing Future

In the realm of manufacturing, structural steel plays a pivotal role, finding extensive applications in various construction and manufacturing endeavors. HGTECH’s structural steel cutting equipment not only enhances the efficiency and precision of structural steel processing but also reduces costs, paving the way for a more sustainable future in manufacturing.

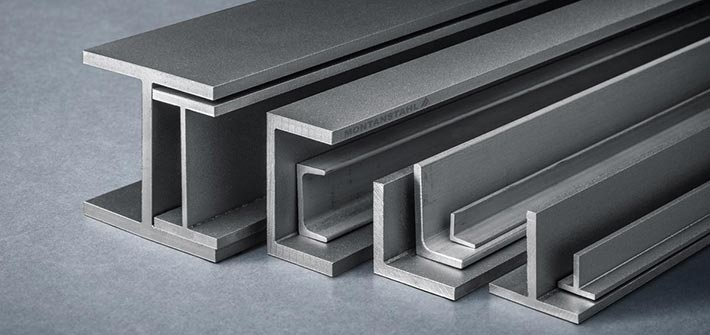

Structural Steel: The Cornerstone of Building the World

Structural steel is a type of steel with specific cross-sectional shapes such as H-beams, I-beams, U-channels, angle irons, and more. These cross-sectional profiles make structural steel widely applicable in the construction and engineering sectors. The strength and stability of structural steel make it an essential component in architectural structures like stairs, beams, columns, and more. Additionally, structural steel finds use in manufacturing machinery, bridges, automotive components, rail transportation systems, and beyond.

Why Use Laser Cutting for Structural Steel?

- High Precision: Laser cutting boasts outstanding cutting precision, enabling the creation of complex geometric shapes. It ensures that components meet specifications without the need for extensive post-processing adjustments.

- Automation: HGTECH’s laser cutting equipment can be seamlessly integrated into automated systems, facilitating continuous production lines. These machines can collaborate with other equipment, such as assembly and welding machines, significantly reducing manual intervention and enhancing production efficiency.

- Versatility: Typically, these machines can process various types of steel, including I-beams, H-beams, U-channels, angle irons, as well as materials of different sizes and thicknesses. This versatility makes them suitable for a wide range of applications and projects.

- Hole Cutting: Laser cutting easily accomplishes hole cutting, meeting the perforation and connection requirements of steel structures, including welding and threading holes.

- Material Savings: Due to laser cutting’s precision, it minimizes material waste, reducing costs.

- Time Savings: Laser cutting is fast and can swiftly complete the cutting and processing of large quantities of structural steel, thus shortening production cycles.

HGTECH Structural Steel Cutting Equipment: The Future Choice for Manufacturing

HGTECH’s structural steel cutting equipment not only enhances production efficiency but also reduces costs and minimizes material waste. Whether you’re in construction, bridge building, heavy machinery manufacturing, or other structural steel processing fields, HGTECH provides innovative, high-performance solutions to help you achieve greater success.

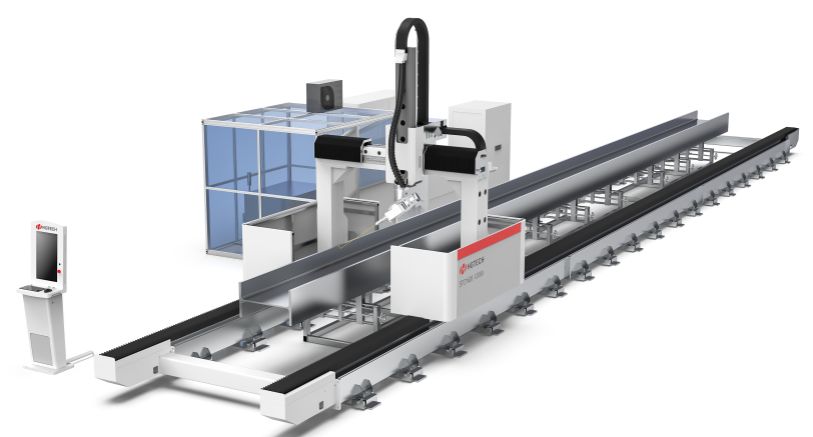

STC Series Structural Steel Laser 3D Cutting Machine

- Open design

- Flexible processing

- Cost-effective

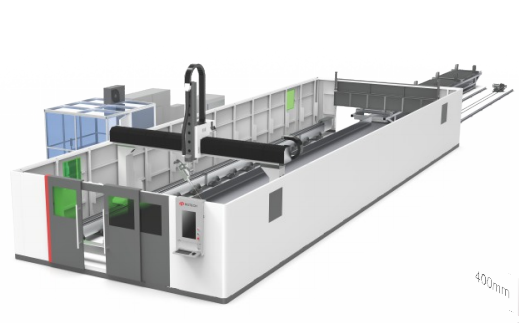

STCS Series double-station Structural Steel Laser 3D Cutting Machine

- Fully enclosed structure

- Double station design

- Safe and efficient

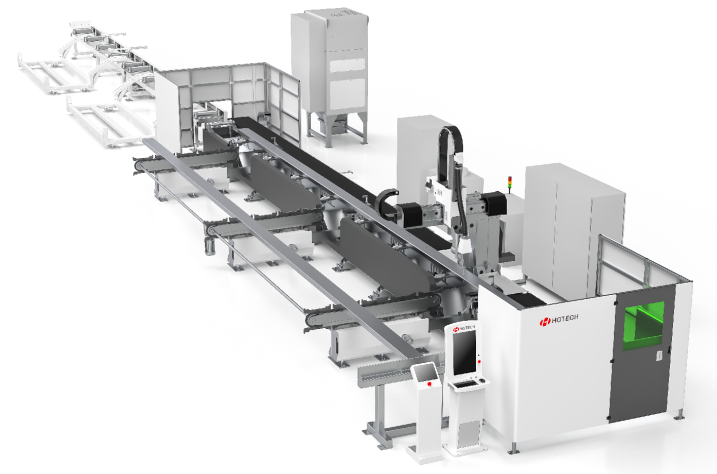

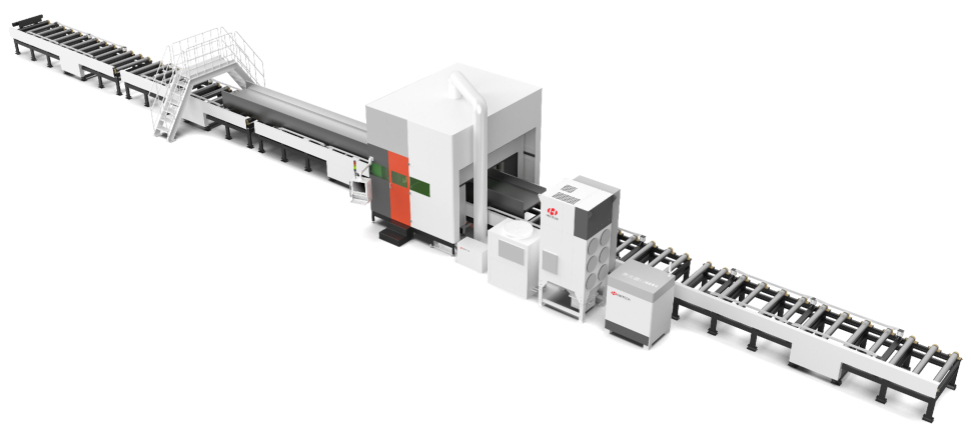

Structural Steel 3D Cutting and Auto Loading&Unloading Workstation

- Automatic loading&unloading

- Automatic deformation correction

- Flexible access to automatic production line

UBC Series Structural Steel 3D Cutting and Auto Loading&Unloading Specialized Machine

- Professional customization

- Automatic loading&unloading

- First choice for batch processing

Robot 3D Vision Cutting Workstation

- Robot +3D visual positioning

- Importing drawings for visual comparison and automatic alignment

- Matching production line

Choose HGTECH for efficient, precise, and safe steel cutting equipment and elevate your manufacturing industry. Together, let’s embrace tomorrow’s manufacturing and make a difference with HGTECH.