Projects

High Quality Metal Processing Equipment:3D Laser Cutting Machines

Laser, born in the 20th century, has become the core driving force of laser cutting technology through continuous development and application. With the modern industrial revolution, laser cutting technology has become a high-tech application technology. Through computer program control, it presents the advantage of flexible processing, greatly replacing the mold stamping process in traditional cutting processes and optimizing production processes.

The development of domestic manufacturing industry is gradually replacing traditional cutting techniques with laser cutting technology. In recent years, the accumulation of experience in laser technology and the development of technology have led to the formation of a stable industrial chain in the domestic laser cutting machine industry. It is not difficult to find that laser cutting machine can be seen in various industries, and three-dimensional laser cutting machines that can achieve three-dimensional cutting are one of the widely used laser cutting equipment in various industries.

At present, 3D laser cutting machines are mainly used in automobile manufacturing. Nowadays, automobile manufacturing is developing towards low pollution and lightweight, and new energy vehicles are a good example. As a powerful support for automobile manufacturing, 3D laser cutting machine equipment is naturally indispensable.

3D laser cutting utilizes the flexible and fast motion performance of industrial robots. Depending on the size of the workpiece being cut and processed by the user, the robot can be installed vertically or upside down to teach programming or offline programming for different products and trajectories. The sixth axis of the robot is loaded with fiber laser cutting heads to perform 3D cutting on irregular workpieces; The fiber laser cutting head is equipped with a follow-up device and a light path transmission device. The laser is transmitted to the cutting head using optical fibers, and then the focusing system is used to focus. Multiple sets of focusing systems have been developed for different thicknesses of plates to cut various three-dimensional metal plates in multiple directions, meeting the needs of customers.

According to relevant data statistics, it can be learned that manufacturers in countries such as Europe and America use laser cutting technology to manufacture 50% -70% of the components of a car. For example, the cutting of parts such as the hood, rear lid box, bumper, leaf panel, door, control arm, rear axle, etc. requires the use of excellent laser cutting equipment such as 3D laser cutting machines.

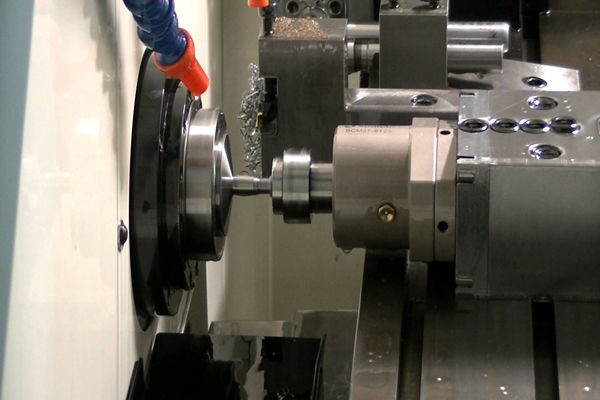

3D laser cutting machines are mainly used in production enterprises that have processing needs for 3D workpieces, such as automotive manufacturing, mechanical manufacturing, and metal processing. It is highly intelligent and can effectively save labor, material, and time costs. In production and processing, it does not require manual repeated angle adjustments. The intelligent setting of the system allows it to cut on any surface of the workpiece. It uses robots as the main body and is controlled through a system, which is very flexible, fast, and stable in performance. Moreover, users can install robots in different forms according to their own needs, such as forward or reverse installation, to ensure accurate cutting of three-dimensional laser cutting machines with different shapes. The principle of the machine is actually similar to that of fiber laser cutting machines, which emit laser light through a fiber laser generator and transmit it to the cutting head through fiber optics. Through system control, it achieves high stability, height, and other characteristics, Double the efficiency of manufacturers.

The 3D laser cutting machine is a laser cutting machine that uses a U-shaped tube laser head. It can perform various processes on three-dimensional processing objects, and can work on any surface on its own without the need for manual angle adjustment. It is one of the essential laser cutting equipment in many manufacturing industries.

About HGSTAR: HGSTAR is is a sub-brand of HGTECH.HGTECH the pioneer and leader of laser industrial application in China, and the authoritative provider of global laser processing solutions. We have comprehensively arranged laser intelligent machine, measurement and automation production lines, and smart factory construction to provide overall solutions for intelligent manufacturing.