Projects

How To Protect The Laser Cutting Machine From Moisture

Because China has a large territory, a wide latitude, a long distance from the sea, various terrain levels, terrain types, and mountain trends, the combination of temperature and precipitation is diverse, resulting in a wide range of climates.

When the temperature rises in the southern region, the air humidity rises, and the walls and ground become “dripping” and wet everywhere. If the moisture-proof protection of the laser cutting machine and other equipment is ignored in this case, it may result in problems such as laser alarm, industrial control computer unable to start, equipment computer black screen, switch trip, and so on, affecting production efficiency.

Following that, HGSTAR will demonstrate how to perform effective laser cutting machine moisture-proof maintenance.

一、Dehumidification

1. Carbon activated

Activated carbon has numerous applications, including air purification, impurity filtering, and dehumidification. The use of an activated carbon moisture-proof agent can lower the ambient humidity of the workshop, lowering the likelihood of failure due to humidity.

2. Keep windows closed on rainy days and open on sunny days.

When it rains or the weather is cloudy, it is best not to open the windows (especially those facing south) to keep hot and humid air out of the house. When the weather is sunny, you can open windows selectively (windows facing other directions) for ventilation to reduce indoor humidity

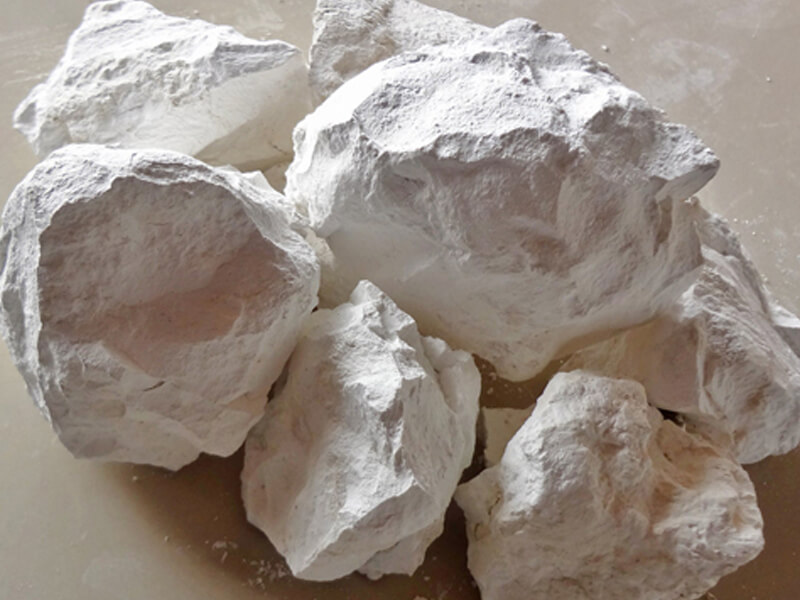

3. Dehumidification with quick lime

According to some materials, 1 kg quicklime can absorb approximately 0.3 kg of water in the air and effectively absorb moisture. If the room is damp and the ground condenses, quicklime can be placed in cloth bags in each corner of the workshop to achieve the effect of rapid moisture removal and drying.

4. Dehumidification of air conditioning

The dehumidification effect of air conditioning is very noticeable in humid climates. Turn on the air conditioner, then the dehumidification function, and then the normal operation of the air conditioner. In this state, the air conditioner functions similarly to a dryer, reducing indoor ambient humidity and ensuring that indoor air humidity is not excessively high, which is very conducive to the equipment’s stable operation.

5. Remove any dust from the electrical cabinet.

Dust and dust particles are easily absorbed by moisture in the air. Regular dust removal for the electrical cabinet can also effectively reduce the cabinet’s environmental humidity.

二、If water vapor appears outside the electric cabinet, do not immediately start the machine.

If there is water vapor on the outside of the electric cabinet, wipe it down first, then turn on the air conditioner (dehumidification function) for half an hour, and then turn on the power supply of the equipment to ensure the safe and stable operation of the equipment.

三、Regular inspection

Check the drainage of the air compressor, filter element, cold dryer, and other components on a regular basis. Avoid contamination of the cutting head lens and the machine tool gas pipeline as a result of the air compressor drainage function failing.

Please pay special attention to anti-static and lightning protection in wet weather. Staff are not permitted to wear slippers and must always ensure that the ground wire is grounded.